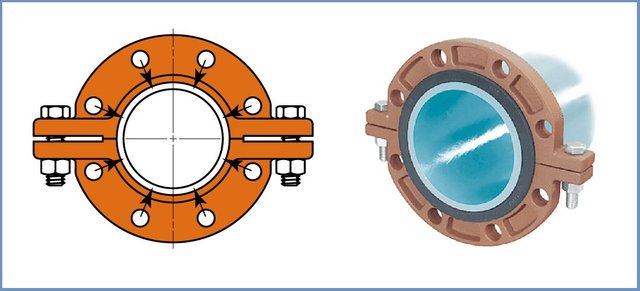

What is a Uni-Flange adapter?

Uni-Flange adapter is used for connecting pipes, valves, pumps, or other equipment to form a piping system. The flanges are mostly used when the piping joints need dismantling, providing flexibility for maintenance. A flanged joint is comprised of three separate but interrelated components such as, the flanges, the bolting, and the gaskets; which are then assembled by the fitter. Most common types of flanges are weld-neck, slip-on threaded, blind, lap joint and many others.

What are the applications of Uni-Flange adapter?

Following are some applications of the Uni-Flange adapter -

Job site fabrication

Uni-Flange adapter are used in job site fabrication to eliminate pre-engineered and pre-fabricated piping systems. When you use Uni-Flange adapter flange, you do not require any threading, welding or grooving. With a plain-end pipe, a pipe cutter and a wrench pipe you can perform pipe fabrication on site. Uni-Flange adapter is ideal for projects that revolve around retro-fitting or renovation of existing piping systems eliminating the need to rely on machine shops or off-site fabricators.

Address bolt-hole alignment problem

As Uni-Flange adapter flanges can be rotated freely before inserting and tightening the flange bolts, it can eliminate bolt-hole alignment problems by giving the facilities of bolt-hole alignment with facing flange, which a pre-fabricated piping system does not offer.

Permits pipe deflection

Unlike other methods, the Uni-Flange offers the installation advantage to permit pipe deflection during installation.

Built-in end restraints

A Uni-Flange adapter flange offers build-in end restraints meaning that no tie rod or other forms of anchoring are needed within normal working pressures. Remember that for surges, special considerations may be necessary.

Future maintenance capabilities

Future maintenance is required for flanged equipment like meters or valves and with Uni-Flange you can dis-assembled and moved back on the pipe easily. It facilitates the removal of flange equipment. So, when it is the time for the equipment to be replaced, simply drop it in it and re-install the Uni-Flange while other flanges like threaded and welled do not offer this feature.

How to install a Uni-Flange adapter flange?

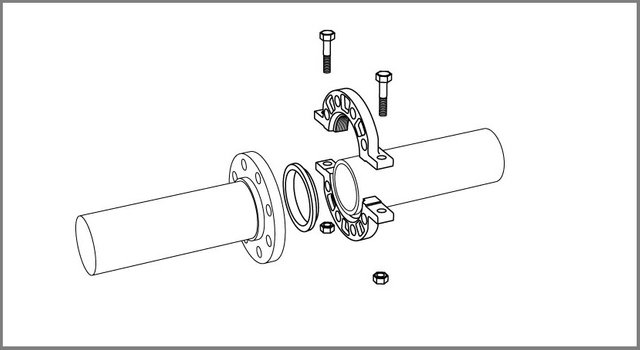

Following are the four simple steps of installing a Uni-Flange adapter:

Step-1

First of all, cut the pipe end to the required length, remember that the cut should be square (for most installations) and make sure it is free from burrs, bevels or shaving. Also, scrape and clean the plain end of the pipe to ensure the proper metal surface for gasket seal and set screw engagement. Afterwards, lubricate the pipe and the gasket thoroughly by using a soap-based pipe lubricant and slide the flange onto the pipe with the gasket cavity facing the end of the pipe. Now slide the lubricated gasket over the pipe end with the tapered end facing the gasket cavity in the flange. Be cautious that no gasket should be used to seal the flange faces, which means no other gasket is necessary.

Step-2

Next, slide the flange forward until the gasket is evenly seated in the flange cavity, and the Uni-Flange face is flushed with the end of the pipe. Make sure the end of the pipe should butt against the facing flange, and it is not more than 1/4” or 6mm from the facing flange, and also hand tighten the set screws against the pipe surface.

Step-3

Now mate the Uni-Flange to the standard flange by using conventional flange bolts. Make sure you evenly tighten the bolts alternately on opposite sides. You could use the star method like tightening the lug nuts on a car wheel. Make sure you do not over-tighten the flange bolts. It is not compulsory to bring the Uni-Flange adapter flange to face to face contact with the standard flange, but a gap (approximately 3mm) between the flanges is normal.

Step-4

Finally, snug down all the set screws and tighten in an alternating manner (e.g. star method) to the torque values specified. It is advised to use a torque wrench.

Conclusion

Using a Uni-Flange adapter flange is helpful for eliminating the need for tie rodding, harnessing, the need for solvent-welding or event other forms of restraints with its power to evenly tight flanged connection. Therefore, if you are looking for Uni-Flange adapter, contact any major industrial control supplier of your area who provides a varied range of Uni-Flange adapter model and choose the right one for you.

All the image credit goes to HITC Australia