With the rapid development and application of cloud computing and data cloud, the substantial increase in data center network traffic also places higher requirements on data center networks and optical interconnection technologies. The emergence of silicon photonics technology has solved how Internet cloud service providers can greatly increase the speed of optical modules while maintaining the same cost, power consumption and size.

Compared with traditional technology, the advantages of silicon photonics technology are its low power consumption, high-speed, and compact structure. With its high integrated features, Silicon photonics technology can be widely used in consumer electronics, intelligent driving, quantum communication, etc.

For simply, silicon photonics technology laser beams instead of electronic signals to transmit data, combining optical and electronic components into a single microchip to increase connection speed. One technical difficulty of silicon photonics technology is that the packaging difficulty of silicon photonics chips is far greater than that of traditional optical devices. Traditional packaging is to couple the optical fiber with the optoelectronic chip through a lens after polishing. One problem with silicon photonics chips is that the mode field diameter of silicon waveguides is much smaller than that of optical fibers, only 0.3-0.5 μm, and the diameter of ordinary single-mode optical fibers is 9 μm, which does not match with optical fibers. The problem is that direct alignment between them will cause severe coupling loss.

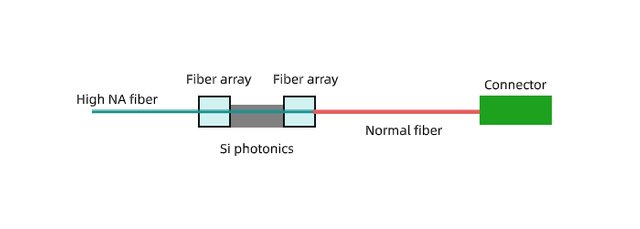

Considering the high integration of Silicon photonics chip, it is better to use a fiber array for chip coupling. Besides, the waveguide of the photonics chip is small, it cannot be coupled with regular single-mode fiber directly. Therefore, some transition processing is needed. Some typical coupling schemes of fiber array are introduced.

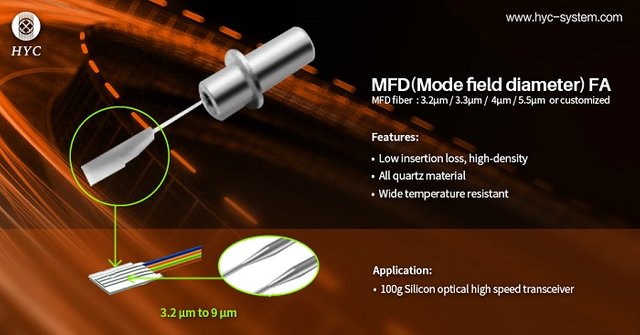

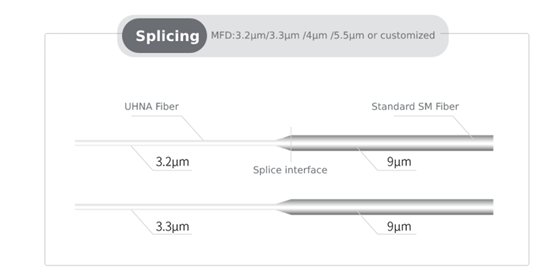

The mode field diameter fiber array (Short for MFD FA) provides a method of low loss coupling to waveguides with small mode fields, using a small section of ultra-high numerical aperture single-mode fiber (UHNA) spliced to the pigtail of standard SM or PM fiber, keeping the fusion point and the surface of the fiber array close to 7mm to achieve mode field conversion. Due to the thermally-expanded core of UHNA fibers, the splice loss to standard fiber is typically less than 0.3dB. The product is an ideal solution for connection on high-speed silicon photonic transceiver module, and can provide customized mode field diameter, such as 3.2μm/3.3μm/4μm/5.5μm to 9μm.

HYC provides a variety of choices of fiber arrays, such as the number of fiber array channels, core spacing and polish angle can be customized. HYC Co., Ltd has been focusing on the OEM/ODM manufacturing of optical passive devices for 23 years with a strong R&D team and production capacity. We can provide customers with one-stop customized production of optical communication passive basic device design, R&D and manufacturing.