The floating fish feed making device cost has to do with several thousand bucks. If it is a fish pellet machine assembly line, it will probably cost tens of thousands to thousands of thousands of bucks.

One of the most vital factors affecting the cost of the drifting fish feed making maker are the model (capacity) of the pellet maker and also the arrangement of the fish pellet device If you are going to do a tiny drifting fish feed mill, you can use a small feed pellet assembly line, to make sure that the manufacturing efficiency as well as degree of automation will certainly be greater.

Nevertheless, if it is a independent family members farming, the result is typically low, as well as a smaller sized fish pellet feed maker can be chosen.

Related post: Floating fish feed making machine

1. Benefits of floating fish feed making device.

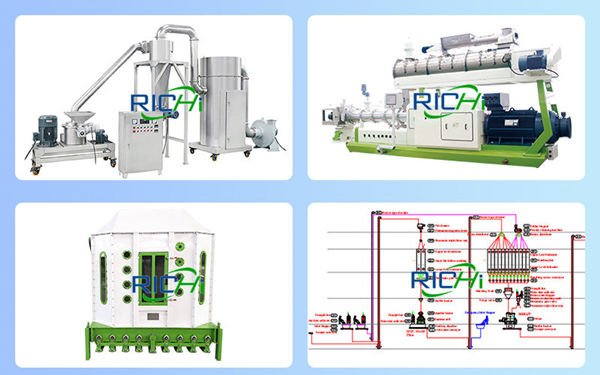

The drifting fish feed making machines generated by Richi Machinery are flexible as well as can be used in feed handling plants of different dimensions, along with livestock ranches of different sizes.

The little feed pellet equipment is made from stainless-steel, which can avoid corrosion or rust, consequently extending the life span of the feed pellet maker and also saving prices.

The drifting fish feed pellet equipment has small footprint, reduced noise and no residue. At the same time, the pellet feed produced by it has high dietary worth and also solid palatability, which is the most effective selection for the majority of users.

The tiny fish feed making device appropriates for different products to ensure the important effect. The extruded granules have smooth surface area, high interior maturity, high granule firmness as well as simple storage.

Compared to the typical pellet equipment, Richi Machinery's little feed pellet device enhances the sturdiness as well as firmness of the product, is a lot more resilient and easy to use, and also extends the life span of the machine.

Related post: Poultry Feed Pellet Making Machine

The feed pellets made by the fish feed floating pellet making machine are more tasty, less complicated to take in, and minimize the occurrence of diseases.

The floating fish feed making device cost has to do with several thousand bucks. If it is a fish pellet machine assembly line, it will probably cost tens of thousands to thousands of thousands of bucks.

One of the most vital factors affecting the cost of the drifting fish feed making maker are the model (capacity) of the pellet maker and also the arrangement of the fish pellet device If you are going to do a tiny drifting fish feed mill, you can use a small feed pellet assembly line, to make sure that the manufacturing efficiency as well as degree of automation will certainly be greater.

Nevertheless, if it is a independent family members farming, the result is typically low, as well as a smaller sized fish pellet feed maker can be chosen.

2. The difference between drifting pellet machine and drifting fish feed extruder:

( 1 ) Various in nature

① Floating pellet equipment: feed pellet maker ( additionally called: pellet feed machine, feed pellet machine, pellet feed forming device), belongs to feed pelleting tools. It is a feed processing equipment that uses corn, soybean dish, straw, grass, rice husk, etc as raw materials, as well as directly presses the raw products right into pellets after crushing the raw products.

Related post: organic fertilizer pellet making machine

Floating fish feed extruder: Feed extruder is a type of extruder, mainly made use of for food extruding, animals as well as chicken feed or for squeezing out a single raw material, and also can additionally be used as the pretreatment of resources in the manufacturing of vegetable oil and alcohol consumption a glass of wine.

( 2 ) Different range of application

① Floating pellet device: feed pellet machine, widely utilized in big, medium and also little aquaculture, grain feed handling plants, animals farms, poultry ranches, individual farmers and small and also medium-sized farms, farmers or large, medium and little feed processing Manufacturing facility use.

② Fish feed pellet extruder: This series of completely dry and also damp extruders appropriate for huge, tool as well as tiny ranches, feed manufacturing facilities and food factories.

3. Crushed pellet size for fish feed granulator

Ordinary fish feed pellet dimension of fish feed resources is listed below 40 mesh, as well as the digestion as well as absorption price is substantially minimized. The squashing pellet dimension of the compound feed for juveniles of common carp, turf, green and also bream need to travel through 50-60 mesh (0.30mm-0 .25 mm), and the squashing pellet size of the compound feed for grown-up fish should travel through a 30-40 mesh screen. 60-0 .355 mm ).

Related post: tofu cat litter making machine plant

Aquatic feed made by floating fish feed making equipment calls for better pellet dimension: the demands of marine items for feed are various from those of terrestrial livestock and also fowl, and also the crushed pellet dimension of aquatic feed is usually better than that of livestock and also poultry feed, generally for the complying with reasons:

( 1 )Digestive capacity. The digestive system system of fish and also shrimp is short as well as slim, and also the proportion of its length to its very own body length is generally much smaller than that of animals and fowl, and its digestion as well as absorption capacity is likewise weak.

At present, the majority of the fish, shrimp as well as crab species that are grown are carnivorous or partial carnivorous omnivorous aquatic items, and the size of their gastrointestinal system is much shorter than that of herbivorous or filter-feeding ones.

On top of that, fish and also shrimps have weak food digestion as well as absorption ability for plant-based grains or cakes, and poor use of raw ( premature) feeds. Therefore, crushing the feed finer helps to boost the usage rate of the feed.

( 2) Feeding atmosphere. Aquatic animals eat in water, and the feed needs to be taken into the water. Therefore, marine feeds are called for to have a particular stability in water to maintain their shape and nutrients from being shed. The smaller pellet size helps to boost the water stability of the feed.

Related post: bentonite cat litter production line

At present, the typical kinds of aquafeed made by floating fish feed making maker are hard pellets, extruded pellets, soft pellets and also dough-like feeds. For the initial 2 types, there is a hydrothermal quenching as well as toughening up extrusion treatment throughout the handling.

Small pellet dimension, water as well as heat are easily transferred to the within the powder pellets, decreasing the distinction in the degree of therapy in between the center and the surface of the pellets, which is conducive to starch gelatinization and protein denaturation in the feed active ingredients.

This change procedure can make the distinction between different powder pellets. Interphase bonding, inlaying, as well as creating secure pellets under the activity of extrusion.

The level of adjustment is big, which can dramatically improve the water security of the feed. For the latter 2 forms, the finer powder pellets are much better bonded to cohesive substances such as starch under the activity of dampness, and the surface of the soft pellets or dough will be smoother, which is beneficial to boost the stability of the feed water.

On top of that, when grating with a relatively fine pellet size, the powder pellets are additionally installed with each other, which is additionally beneficial to the stability in water.

( 3 ) Individual size. Individuals that breed marine items are typically not as big as livestock and fowl, and also their calibers are additionally tiny. For the same water types, the ended up item made by drifting fish feed making equipment is countless times larger than the private plants.

Especially for fish, shrimp and also crab fry, the pellet dimension required for squashing is alike smaller sized.

4. Floating fish feed making equipment types

( 1 ) Pellet feed treating tools

In order to prevent the pellet feed from dispersing immediately in the water, a steam treating gadget is normally included in the difficult pellet feed machine to enhance the cohesion of the feed .

( 2 ) Extruded drifting fish feed making equipment

In order to establish brand-new feed resources, squeezed out pig hair, feathers, as well as livestock manures are made use of for feed. In order to eliminate toxins such as gossypol, puffed soybean meal, veggie cake, cottonseed cake, and so on.

( 3 ) Pellet feed coating devices

In order to extend the qualitative time of pellet feed in water, an oil splashing movie tool is usually set up at the electrical outlet of floating fish feed making maker. Nonetheless, because the moisture material of pellets was high during that time and also the wetness content of the completed item was more than 16%, it needs to be dried initially and afterwards splashed .

( 4 ) Devices for fresh soft pellet feed

The fresh feed is made right into a paste with a beater, mixed with various other powdered feed, as well as processed into fresh soft pellet feed to keep the energetic materials of the online feed .

( 5 ) One-step floating pellet equipment

The drifting fish feed making machine does not require to include water vapor as well as feed during the handling, dry in and dry. When the moisture content of the raw material is less than 12%, the dampness content of the product is less than 10.2%, as well as no drying out is needed .

( 6 ) Tools for processing pellet after sinking and then floating

Its product is the prawn pellet feed advised by the United Nations. It does not degenerate after being launched into the water, as well as can float to the surface area after a few hrs, which can lower the pollution to the water body as well as save the feed .

( 7 ) Typical temperature level and normal pressure equipment

The sort of floating pellet maker does not need heating facilities, as well as the pellet feed refined under regular temperature as well as pressure can " drift right away", and also float for numerous hours without degenerating .

( 8 ) Equipment for ultra-fine grinding as well as processing

In order to make the feed very easy to digest as well as take in, the sieveless ultra-fine grinding modern technology is typically made use of to feed bigger plants, and it can also be made use of as the raw material of pellet feed .

( 9 ) Full tools for microcapsule feed processing

It can make the micro-pellets naturally layered, and afterwards spray-dried to develop.

More details: https://www.richipelletmachine.com/floating-fish-feed-making-machine/

5. Floating feed maker price.

The huge and medium-sized drifting fish feed making machine is the fave of lots of users with a huge range of farming, due to the fact that this model has huge outcome, high production efficiency, low power intake, high pellet creating price, simple device procedure and easy to use, as well as the rate of the pellet machine is modest. The 400 type floating feed extruder maker belongs to the ring die cost-effective feed equipment.

( 1) Functioning concept of huge fish feed pellet equipment.

The electric motor drives the main shaft through the hypoid bevel equipment, and also the primary shaft drives the pressure roller to turn. When processing raw materials, the raw materials are fed right into the feeding chamber of the ring die drifting feed equipment rate, as well as the materials all fall on the ring die.

The primary shaft drives the stress roller to rotate, the stress roller continually rolls via the material layer, and also squeezes the material right into the die opening. The blade reduces the material to form pellets, as well as the pelletss are sent out by the throwing disc.

( 2) Product functions of drifting feed equipment price.

The seal of the pressure roller as well as the major shaft bearing takes on a fully enclosed layout, the bearing and grease are free of pollution, the bearing life is long, and the floating feed maker cost maintenance time is conserved.

The general pushing roller takes on three-roller style, which improves journalism work effectiveness, and the pressing roller has a wider range of basic materials.

The product of the die plate is completely upgraded, alloy steel is created as well as refined, and also after vacuum heat treatment, the material is wear-resistant, high in hardness as well as long in service life.

The die opening of the die plate is refined by automatic CNC drilling, with high processing precision as well as good surface, which can improve the equipment productivity as well as lower the manufacturing cost.

The reduction box of the drifting feed machine rate embraces hypoid bevel equipment, which has high transmission efficiency, secure transmission, high bearing capability, dependable procedure, portable framework, energy conserving, product conserving, room conserving, put on resistance, long life and low noise.

For details please contact: Richi Pellet Machine

WhatsApp:86 138 3838 9622

Email:[email protected]

You've got a free upvote from witness fuli.

Peace & Love!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Wahoo! Resteemed!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit