Operate the sewing machine

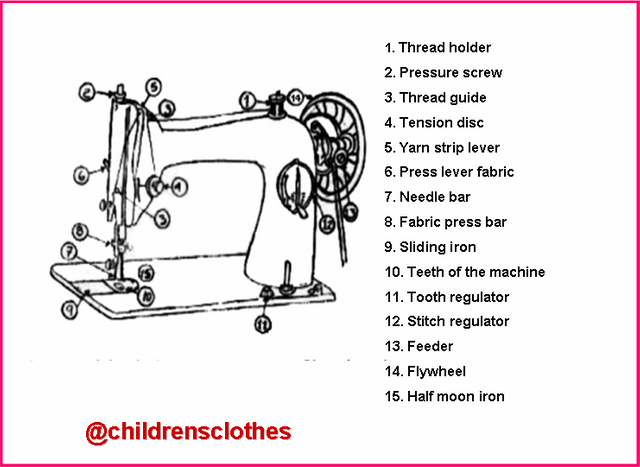

The parts of the pedal sewing machine.

The Sewing Machine is the set of combined mechanisms that allow to make most of the sewing and embroidery points mechanically.

In the year 1945, in the United States, Elías Howe patents a first sewing machine. Five years later, Isaac Merrit Singer patented his sewing machine model, with a single thread and chain stitch, perfecting that of Howe. In the last hundred years more than 45,000 inventions of sewing machines have been patented.

Terminology

Wire holder: Part of the machine used to locate the thread spool.

Pressure screw: Part of the machine that allows pressing the presser foot.

Tension discs: Part of the machine in the form of cymbals that allow loose stitching.

Thread strip lever: Part of the machine in the form of a lever which, by having movement from top to bottom, allows the thread of the cone to be unwound.

Presser foot lever: Part of the machine in the form of a lever that manually operated allows moving the presser up and down.

Needle bar: This is the part of the machine where the needle is held by the needle screw.

Presser bar: It is the bar that has the machine to hold the presser with the screw.

Sliding plate: It is the part of the machine that when running allows to introduce the coil with thread to the box of the coil and cover the lane.

Drag system (teeth): They are the part of the machine that having forward and backward movements allows the advancement of the fabric.

Tooth regulator: It is the part of the machine in the form of buttons that when rotating it allows to raise or lower the teeth according to the need of the sewing that has to be done.

Stitch length regulator: It is the part of the machine in the form of a lever that moving it up or down allows you to make the stitch shorter or longer, as needed.

Winder: Part of the machine that allows winding the yarn.

Steering wheel: It is the part of the machine that when rolling it in coordination with the pedal allows the general movement of the machine.

Half moon iron: It is the part of the machine in the form of a semicircle plate that allows the exit and movement of the teeth.

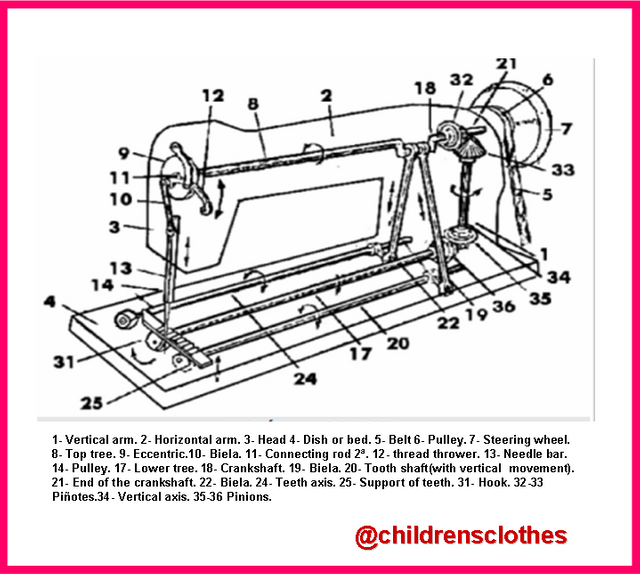

Structure of the sewing machine

The mechanical complex in which the sewing machine is integrated is divided into two fundamental parts: the bench and the board; they are the sustaining organs of the machine.

The pedals with which it controls the starting and stopping of the driving mechanism and the speed of the latter are installed on the bench.

The board can be supported either on legs, as a table, or on the column that starts on the bench, and allows to regulate the table height. This second case is the most frequent among industrial machines.

The board houses the accessories box and supports the body of the machine, which is divided into two groups: transmitter and operator groups.

Remember

To sew the fabric the teeth must be high and to embroider down.

To make basting the stitch length regulating lever has to be in the most number

high and to embroider in zero.

(1) Vertical arm: it is the support of the horizontal arm. It holds the pinions and the vertical axis, transmitter of the driving force to the lower shaft; the crankshaft and the cranks, transmitters of the movement to the axes of teeth.

(2) Horizontal arm: it is the support of the head. Interior ensu

find the upper shaft, from the crankshaft to the eccentric wheel, which transmits the movement from the steering wheel to the head of the

machine.

(3) Head: contains most of the elements

Sewing machine operators:

Needle bar mechanism (13)

Presser bar mechanism

Needle thread tension mechanism (4)

Plate or bed: is the base of the head. Houses elements transmitters and operators:

The lower tree (17)

The tooth shafts (20)

Shuttle mechanism composed of two mechanical sections: the feed or drag mechanism and the needle plate.

How does the sewing machine work?

The machine head

Elements that make it up:

Needle bar mechanism

The presser bar

Needle thread tension mechanism

The head and the bed are the essential organs of the machine, where sewing takes place.

Needle bar mechanism

It is the first of the mechanisms that houses the head of the machine; they form it: the needle bar and the needle.

The bar of the needle is a solid and resistant piece that in the lower end fits the needle of sewing and in the superior one it is coupled to the crank of the eccentric wheel (9), wheel that drives the needle bar in its movement of vertical and continuous oscillation.

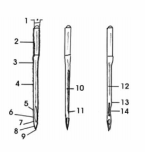

The needle

The needle is the basic element of the sewing machine, but it is, at the same time, a particularly delicate piece. Subjected to the hard work of perforating the fabric and carrying the thread to each stitch, it must also do so with total precision. With the progressive increase of the speed, each new generation of machines needs of the needle a greater

quality, resistance and improvement of the stitch. A normal needle of industrial sewing machine is divided into the following parts: Heel, cone, trunk, grooves, inlet, eye and tip.

Diameter or thickness of needle

Nm: Needle number: It is the thickness of the diameter in the cylindrical part of the trunk of the needle, above the recess of the short slot, not in the reinforcement part of the trunk. Currently the needle diameter, its Nm, it has been standardized. Always this value is given in hundredths of mm. In this table we see, for example, that the Nm 70 corresponds to the needle that Singer calls 10, the 7 of Pfaff, the 3/0 of Mausser,

2.5 from Lewis and 3/0 from Reece.

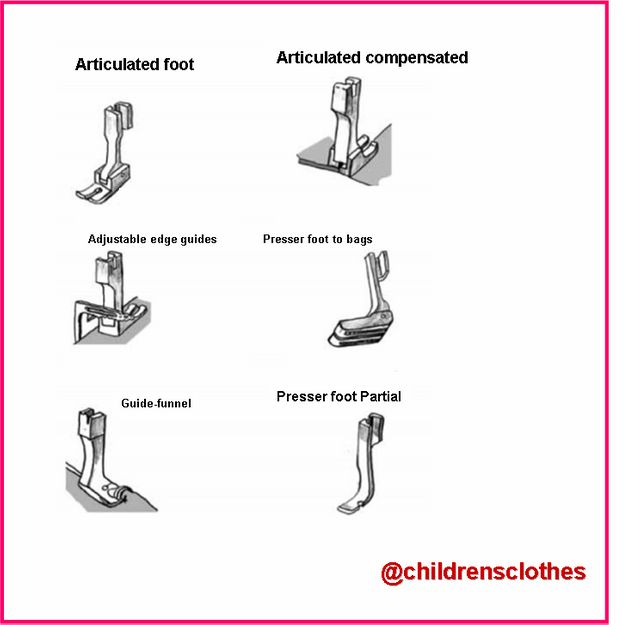

Presser bar mechanism

It is the second mechanism in importance, inside the head of the sewing machine.

Your foot is the presser foot.

The whole of this mechanism has the mission of fixing the gender that is sewn (during the stitch) on the trailing teeth and help that these pull the genus in the opposite direction to the advance of sewing.

The presser foot

It is the piece of the machine responsible for preparing the fabric and, together with the drag system, handle it

moving it with precision to be sewn.

Tools and sewing machine

Types of presser foot

Tension mechanism of the needle thread

The third of the mechanisms inside the head of the machine consists of the following elements: the thread take-up, pressure discs and compensator spring.

The thread take-up (12) is a lever with one end on the axis of the eccentric and a fixed point of support on the head; release and tighten the thread that goes to the needle, before and after, respectively, of the stitch. It serves this way to remove the thread from the bobbin or cone, first, and to recover the excess thread, by pressing the stitch, after

done this one

There are two concave discs, pressed together by an adjustable spring. The compensating spring, located next to the tension discs, keeps the thread in a minimum and constant tension, avoiding jerks.

The plate or bed of machine

It is the base of the head and houses transmitting elements of the driving force and operators of dragging or feeding of fabric or material to be sewn. Elements that make it up:

The lower shaft (17) and the tooth shafts (20).

Shuttle mechanism.

Feed or drag mechanism.

The needle plate.

The shuttle mechanism receives its driving force through the lower tree.

This mechanism is the one that, with its movement, forms the stitch, together with the needle and with the fabric itself. The shuttle forms several pieces. The shuttle tip is the one that hooks the thread loop to make the stitch. According to the different types of machines, the Shuttle can be in vertical or horizontal position and be a complex of more than one shuttle.

The art of synchronizing perfectly the movements of rotary and needle is achieved by means of toothed systems, of belts, chains or pinions. There may be one or several motors in the same machine and it is the electric current itself that feeds those quartz motors the one that controls its speed with absolute and constant precision. In one of these turns, with the needle down, the point B of the hook grabs the loop of thread together with the needle, and the back plate retains it. The wing A repels the thread of the loop towards the outside, taking it to pass around the bobbin. Heel C holds the loop while closing, until the moment of disengagement.

Tools and sewing machine

The bobbin is the lower thread store. If the bobbin goes into the rotary hook system, its bobbin is inside the bobbin case or bobbin case, rotating only by pulling the thread. The hook

It revolves around the canillero. The lid of the canillero, by means of a spring, regulates the tension of the thread between the hook and the bobbin.

FROM LEFT TO RIGHT: The box of taps. The Shin. The intermediate piece.

Mechanism of feeding or drag of gender

The driving force arrives at the mechanism of drag by the axes of teeth, connected to the crankshaft by two connecting rods that cause them to move back and forth. The two systems of teeth have two movements, one in a horizontal direction and another that also oscillates but in a vertical direction.

In those combined movements, the teeth drag the genre imprisoned between them and the presser foot, whose pressure, can be regulated as necessary. The teeth can also vary in size and shape. A normal sewing takes five stitches per cm. The more powerful the drag, the heavier and more bulky can be the fabrics to sew. In the following graphs we have the overview of the drag operation.

Contact Data

In addition we will have channels available for questions, suggestions and personalized attention through email and discord.

[email protected]

[email protected] or chat with @childrensclothes#7556 on our Discord

You can also enjoy updated information on events and models from our Aurora collection, follow the Instagram account: Vastagocasademodas.

We accept payments in Cryptocurrencies Steem, Sbd.

Why support @childrensclothes?

By supporting this productive social program will be contributing to a solidarity project for children in Venezuela who have no shelter, food and medicine, will be strengthening the productive apparatus and the ability to generate jobs to mothers head of households, will also contribute to maximize the level educational with training for entrepreneurs in various trends, financial, commercial, business, personalized courses, will also be promoting the inclusion of special children Autism, Down syndrome, and children with cancer that occupy a special place. Preventive measures to care for the environment The use of the blockchain will be established as a technology with purpose, and to empower leaders in action to form their own companies, in a self-sustaining model through efficient resource management.

"If society improves, it will improve the performance of the company. You can not be happy alone, I can not do well in the middle of a failed society "

FASHION WITH PURPOSE: THE BEST COAT, IT'S LOVE

YEAR 2019. The goal is to enjoy childhood in all its colors, aromas and flavors.

We thank our collaborators:

___-

This project is being supported by @Fundition the next-generation, decentralized, peer-to-peer crowdfunding and collaboration platform, built on the Steem blockchain.

Read the full details of Fundition Fund program

Learn more about Fundition by reading our purplepaper

Join a community with heart based giving at its core

Fundition is a non profit project, by supporting it with delegation you are supporting 200+ projects.

50SP100SP200SP500SP1000SP2000SP5000SP10000SP

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Good tutorial, there is a lot to practice and learn from all this, thanks is very good initiative.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit