Any wristwatch has three major components, namely,

1. Watch case, which is housing the mechanism,

2. The mechanism or module with dials & hands,

3. The strap to wear the watch on hand.

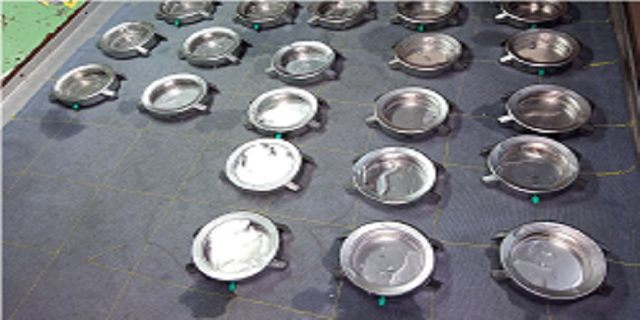

Watch case is a subassembly with glass, back cover and case pipe (to guide stem meant for time adjustment using crown). This subassembly is carried out at the in-house watch case plant that has five major shops–

1. Press shop

2. Machine shop

3. Polishing shop

4. Plating shop

5. Watch case assembly.

In watch case assembly, case center, back cover (BC), case pipe (CP), and glass are assembled together and later tested for joint-strength and water resistance (WR). The WR test is a mandatory statutory requirement for watches and is done through water immersion method where watch cases are soaked in the water for 10 minutes with the pressure of 5 Kg/cm2 or 7 Kg/cm2, based on specification.

To attain this WR property, all the joints mentioned above should have specified strength i.e. glass joint to withstand a minimum of 4 Kg/cm2, BC joint to withstand a minimum of 5 Kg/cm2 and CP to withstand min pressure of 3 Kg/cm2. This strength will ensure the mating parts are intact when the watch is in worn while riding a two-wheeler, running, jumping, etc., as well as resisting entry of water/moisture during testing/use because of outside pressure being higher.

As per horology standard and know-how, a glass joint is made using a plastic gasket, adhesive, sticker, and ultrasound welding in case of acrylic/plastic. Each of this method will have a certain advantage for each kind of design or configuration and quality; e.g. gasket is good for round models with flat glass (ensures higher WR), whereas, an adhesive is good for shaped models with a sharp corner for moderate WR.

Different design demands different method of glass joint/assembly with desired quality. This puts pressure on the production system to maintain the tolerance, and on the designer to forgo his design ability because of this constraint. Hence, the challenge is to ideate and implement an alternate method for this glass joint which is universal for all designs.

Options Tried:

- Sticker type joint was tried where the pressure-sensitive adhesive is used. It demands metallization (metallic coating of the plastic component) band-width of 1.5mm.

- Hot melt glue, which forms a sticker type joint when it is heated at 120 oC for 1 hour, was also tried. However, such high temperatures have an adverse effect on plating quality.

Solution Requirements:

- The alternate method of glass assembly should be universal for all designs and meet all desired requirements.

- It should not pose any restriction or constraint on the design or shape of the watch case.

- It should provide high WR (up to 25 ATM for diving purpose) even in asymmetric shapes.

- Any shock load shouldn’t induce hairline cracks or other failures in WR.

- The new joint type should provide higher quality at optimal cost with ease of production for the manufacturer.

- Also, this alternate method should prevail throughout the world, i.e., it should have no geographical constraints.

- The customer should be able to use and operate all type of watches, without knowing the preconditions of any watch type.

Awards:- INR 5,00,000

Deadline:- 02-11-2019

Posted from my blog with SteemPress : https://givemechallenge.com/universal-glass-joint-for-watch-cases-challenge/

Warning! This user is on our black list, likely as a known plagiarist, spammer or ID thief. Please be cautious with this post!

If you believe this is an error, please chat with us in the #appeals channel in our discord.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit