You came as a child to play with the Lego bricks, where you could build tracks, toys, bridge what you could imagine. Today I present a social and ecological project.

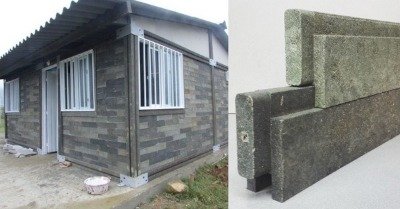

It is the construction of bricks (in the form of Lego) with recycled plastic, these bricks are intended to build a house at very low cost, apart from not needing specialized labor.

This brick is made for a very high strength and stiffness, in addition to its semi-double characteristics, makes it resistant to earthquakes and heavy rains, this system reduces the plastic that reaches the landfill thanks to the use of this plastic in the bricks, in turn it reduces the consumption of water and energy, as well as the reduction of CO2 emissions.

The BRICKARP system is made of recycled plastic and its guarantee extends to the terms of biodegradation of the raw material of these (3,000 years). These blocks contain recycled plastic, are thermoplastic polyolefins of high rigidity, crystallinity, high melting point and excellent chemical resistance. The blocks are light, modular and can be easily coupled, and do not require specialized labor.

This system seeks to offer an alternative future for the manufacture of structural and non-structural elements for the construction of architectural projects, generating an integrated construction system with lightweight elements, resistant to the modules, allowing fast, safe and economical installations.