Here is an example of how rapid prototyping can be used in the domestic environment.

This description is divided into the following chapters:

-THE STAGES OF RAPID PROTOTYPING

-WHAT I NEEDED

-MY HOMEMADE MANUFACTURING PROCESS

Here are the chapters:

-THE STAGES OF RAPID PROTOTYPING

The fundamental stages of production in rapid prototyping are 3:

1-Design

2-Print 3d

3-Application

-WHAT I NEEDED

What I needed were feet for some plastic lockers that didn't have supports. These lockers were built to rest the base on the ground, but this situation makes it impossible to clean under the lockers where dirt accumulates. After using the lockers for a few days, the need to lift the base off the ground immediately arose. At this point I started thinking about how to produce feet to apply to the base of the lockers.

-MY HOMEMADE PRODUCTION PROCESS

1-Design

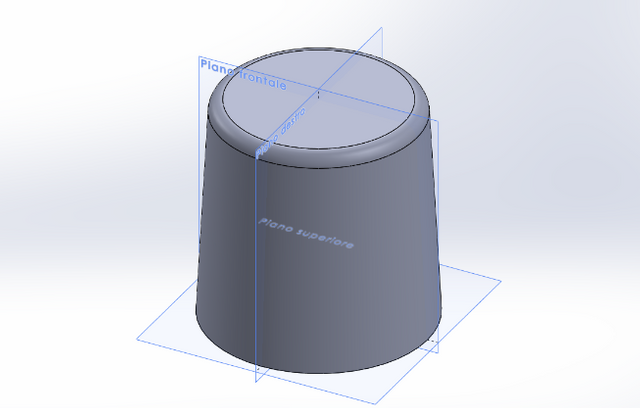

With solid modeling software I modeled a foot. Here is a screenshot of the particular modeled foot.

2-Print 3D

For 3D printing I used a Sharebot 42.

The material I used to print is Nylon-Carbon. Here is a set of feet that I sent to print. Nylon-Carbon, as the name suggests, is a material composed of nylon and carbon fibers. Nylon gives the material toughness and resistance, while carbon makes it light.

3-Application

Below is a photo of the upside-down cabinet in which the printed feet have been applied

Below is a picture of the locker put back in its correct position with the feet lifting it off the ground.

CONCLUSIONS

When the prices of 3D printers drop further, many of us will use them and find lots of objects to build for home applications.

That's really great. Do you know if there are any toxic fumes?

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

If PLA material is used there are no toxic fumes. For this Nylon-Carbon material I have no information. But I can tell you that I printed 12 feet in a closed room and I didn't smell any smells.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

That's a great thing this 3D printing :D

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit