Hi ! Any FDM Printer has either a direct drive or a bowden extruder.

There is a third way: the remote direct drive extruder.

Quick Recall

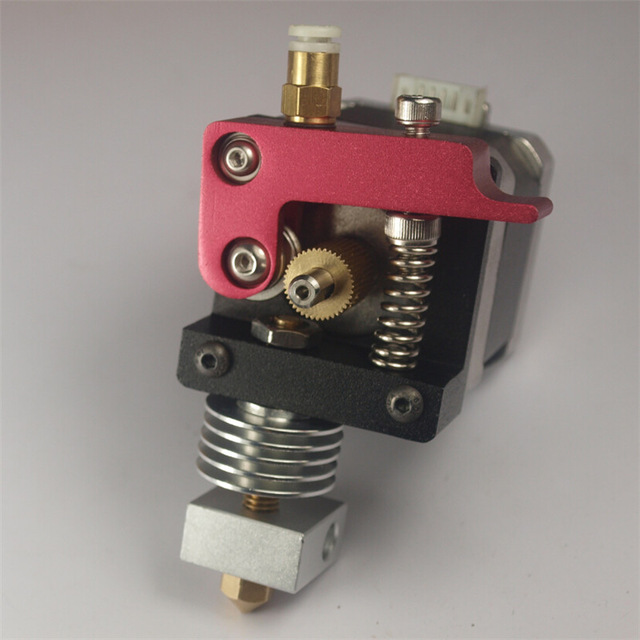

A direct drive extruder has its name implies pushes the filament with a gear hob driven by a stepper motor in the heat throat of the hotend.

A bowden extruder has a so called bowden tube that is directing the filament pushed from the gear hob driven by the stepper motor.

Direct drive

Pros:

- Very short and More constrained filament path: sharper reaction, improving print quality

- Print flexible filaments

- Short retractions

- Less oozing improving print quality

Cons:

- Weight, Inertia: Difficult to accelerate fast

- Vibrations affecting print quality

Bowden

Pros:

- Weight, Inertia: Easier to accelerate fast

- Less vibrations improving print quality

Cons:

- Long and less constrained filament path: lazy reaction, reducing print quality

- Cannot print flexible filaments or very slowly

- Long retractions

- More oozing reducing print quality

- Difficult to really implement it correctly (any source of play is introducing hysteresis and longer reaction)

The Remote Direct Drive Extruder

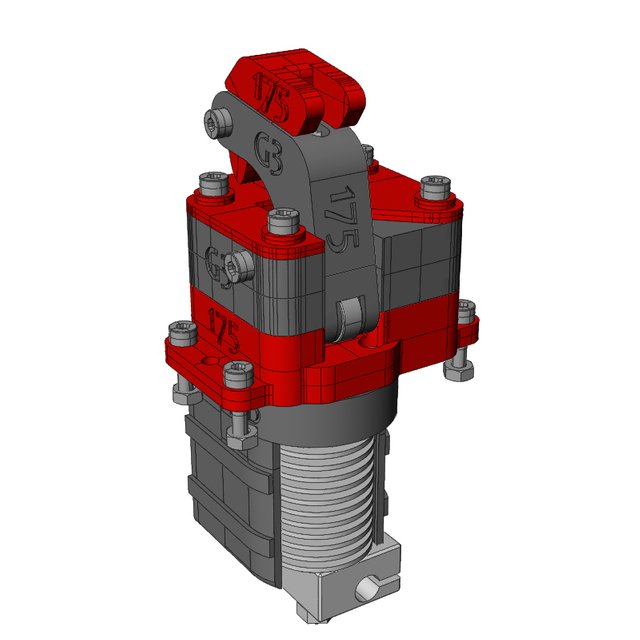

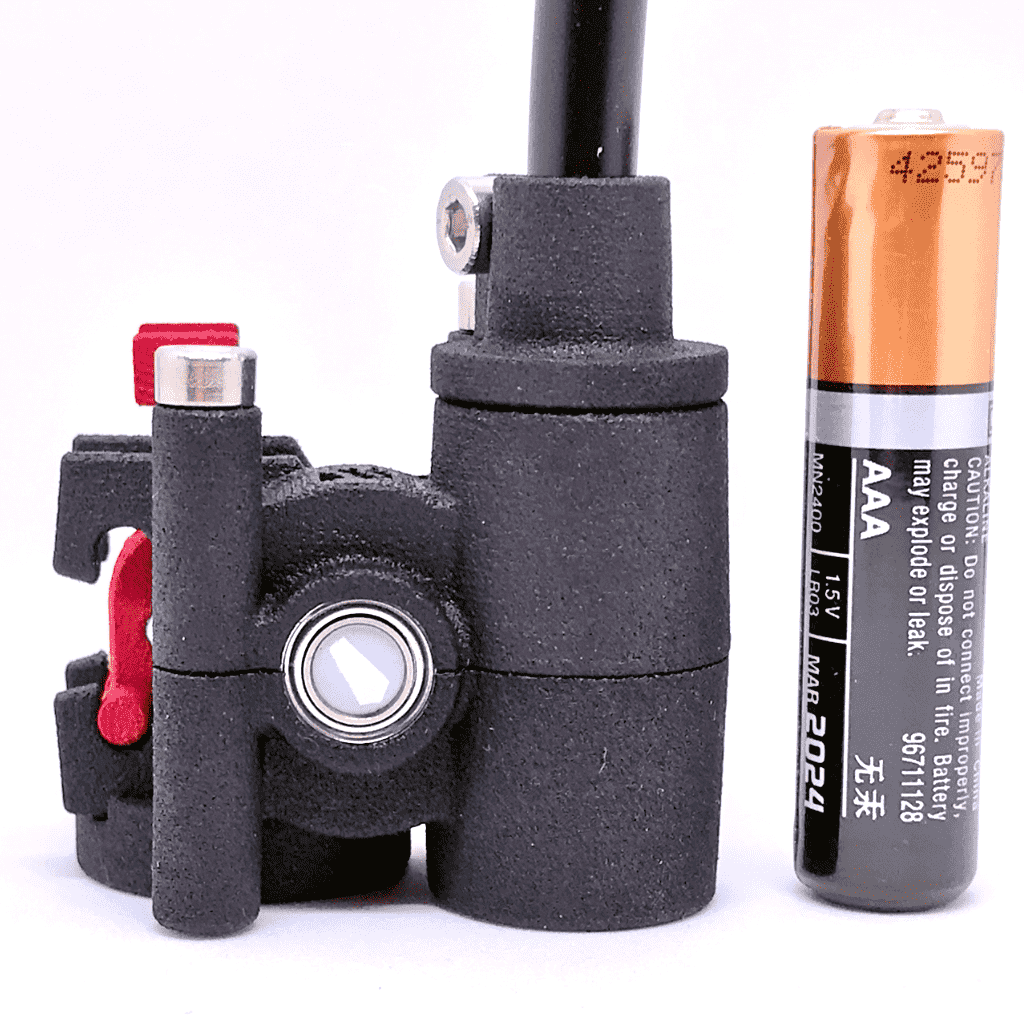

The Remote Direct Drive Extruder is using a constrained cable that connects the stepper motor to a driven gear reductor (worn gear) that is pushing the filament directly in the heat throat of the hot end.

The stepper motor is outside of the gantry just like a bowden extruder, the gear/assembly and the hob driving the filament is on top of the heat throat.

Yes, it looks like a remote Dremel or something like that.

It seems to be as good as the Bowden for the weight, inertia but also allowing a very short and constrained filament path that is needed for sharp reaction and to enable to print fast enough flexible filament.

Is it so good ? I think it is interesting on the paper, but as usual the implementation makes the final decision.

There are two options:

- Flex3Drive: https://flex3drive.com/flex3drive/

- Zesty Nimble: https://zesty.tech/collections/the-nimble

Both products are very similar: compact, lightweight and using a worn/gear.

The Flex3Drive has a 40:1 reduction and the Nimble has a 30:1 reduction.

They have both good reviews.

The weight is around 30 to 60 grams.

Pros:

- Weight, Inertia: Easier to accelerate fast

- Very short and More constrained filament path: sharper reaction, improving print quality

- Less vibrations: improving print quality

- Print flexible filaments

- Short retractions

- Less oozing improving print quality

Cons:

- Input torque limited for the driven cable (reliability and hysteresis issues)

- Max speed limited by the stepper motor (high gearing): low inductance/low inertia stepper motor, high voltage (cheap stepup voltage circuit is an option), probably moderate microsteps or even none.

Others:

- Backslash is not an issue, lot of people are using geared steppers for Bowden.

- Limited Acceleration of the retraction due to the high gearing: it is not a good idea to have a huge acceleration on the extrusion part if you want to go fast.

Personally, I think I will give a try to one of those

You got a 33.33% upvote from @proffit courtesy of @boucaron!

To get upvote send at least 0.01 SBD/STEEM to @proffit , your post link as memo

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

I didn't understand how this new drive should work. Isn't that like a motor again on the print head or where to you position the remote drive extruder ?

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Sorry I should have put an image, it will be more clear.

The worn/gear assembly is attached as a regular direct drive extruder on the hotend, but instead of having the stepper motor, you have a cable that is driving this gear assembly that goes to the stepper motor attached to the chassis

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

I edited the post to add the missing photo

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thanks now I got it :) nice design gonna be interesting to see it in a prosumer printer.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

They are doing custom designs: the case is 3D printed for both companies.

For instance: https://flex3drive.com/flex3drive/f3d-range/

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Cool they also have it for UM2+

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

You got a 12.50% upvote from @childfund courtesy of @boucaron! @childfund is a bid bot to help the steem community sponsor a child.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

You got a 5.72% upvote from @thebot courtesy of @boucaron!

Please delegate us Steem Power & get 97% daily rewards share!

20 SP, 50, 75, 100, 150, 200, 300, 500, 1000 or Fill in any amount of SP.

Click For details | Discord server

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

You got a 18.75% upvote from @bodzila courtesy of @boucaron! Join our Discord Channel https://discord.me/SteemBulls for support & feedback

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Wow greate article!

Thanks for using the @postdoctor service!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Join our Discord Channel to connect with us and nominate your own or somebody else's posts in our review channel.

Help us to reward you for making it ! Join our voting trail or delegate steem power to the community account.

Your post is also presented on the community website www.steemmakers.com where you can find other selected content.

If you like our work, please consider upvoting this comment to support the growth of our community. Thank you.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

You got a 25.00% upvote from @lrd courtesy of @boucaron!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit