Hi guys !

First a late happy new year ^^, long time I did not write something.

This afternoon, I was doing some cleanup and I saw my large tower under my desk. I cannot put the hoover under and it is very heavy and not easy to move.

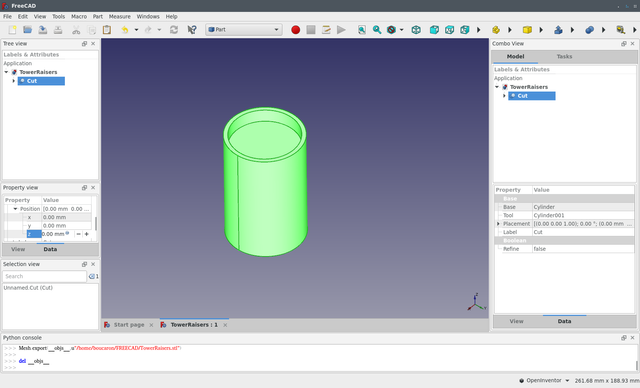

Let's raise the tower with 4 foot underneath. So just a simple and stupid design under FreeCAD and that's it: 2 cylinders and a small difference.

Checking the first time estimate on the slicer, I was upset more than 7 hours for this simple stuff with 0.4mm nozzle, 30% Strong Hex infill, 1.2mm shell thickness on XY and Z with max speed at 35mm/s. This speed is the sweat spot for the print quality on this machine.

I just think, how can I speed up this.

This design has interesting properties. First, there is no overhangs, so I can use whatever extrusion width my nozzle/extruder is able to handle, and I do not need any cooling fan (stronger) and I can put a very high temperature instead of regular one.

So I just put 0.8mm all around (1.6mm shell thickness on XY and 1.2mm on Z).

Also I was lazy and did not want to remove the 0.4mm nozzle and put a 0.8mm nozzle instead...

Slightly better with about 4 hours and nearly 100 grams of material ^^.

This thing is really strong.

So I thought, let's push further with 0.25mm layer height, but it is really the limit throughput on this setting. Hopefully, the printer do not run at 35 mm/s long enough but there is the tick tick noise on the extruder from time to time. About 3 hours, it starts to be interesting.

Follows a close up to show the internal of the thing, the ooze in the hex infill shows the small diameter used to print this

The thing is that it is different to extrude a lot of filament on a regular 0.4mm nozzle than a big 0.8mm nozzle. Higher pressure and this plastic following a Non Newtonian behavior, even if the viscosity is "lower" due to the slightly higher temperature, both are putting a lot of stress on the extruder.

Very happy by this small experiment: less moves, more throughput, less time.

Of course, it only works in cases where you know the geometry of the part is suited for this kind of trick: hopefully many simple parts ^^.

Happy printing !