In today's competitive market, your product development plays a vital role in determining where your company stands. In order to design a flawless product, an appropriate research and prototyping process is essential. But, apart from creating a high-quality product that caters to the need of folks, you should also consider the development time. Make use of the reliable rapid prototyping services in China.

It goes without saying "the faster you design your brand and bring it to the marketplace, the higher is the probability of your company taking over the competition. In this fast-growing economy, rapid prototyping is a key element in designing your material within a short timeframe.

Now the question is what exactly refers to the rapid prototyping process? Which material can be designed using this approach? And, which prototyping process can help your company to develop top-notch materials in a short period? Read on to find the answers:

Rapid prototyping technologies

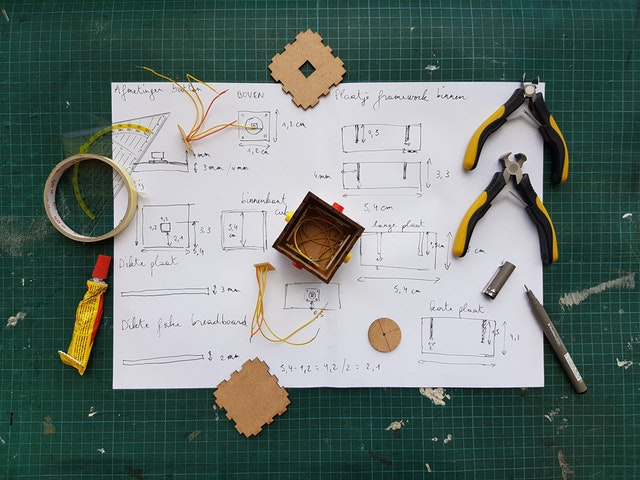

The rapid prototyping process involves the production and designing of your material using the advanced CAD technology. Note that there have been several conventional tools that design product in a short time span, but the rapid prototyping technologies include the latest machinery which not only produces your brand shortly but without compromising the quality. Hire reliable rapid prototyping services in China.

Here are some factors to consider before choosing the right prototyping process for your company:

- Level of quality: Which type of prototyping project is your company focusing on? For instance, are you looking for a machine that could cater to your medium fidelity or low fidelity requirements? Or your firm is working on a functional prototyping project?

- The complexity of the material: Not every material could be processed using SLS prototyping method, and especially if the parts you are planning to shape are intricate. While some casual materials do not need an effective prototyping machine, you might require a CNC machine for complex metals which need sharp tools to be cut and shaped.

- Quantity: Another factor that can affect your decision of buying an accurate prototyping tool is the quantity of the materials you'll be passing through the machine. Make sure that some tools, though claims to offer a rapid prototyping outcome, can only handle a small volume of materials. If you're looking for a reliable tool that could design the large volume of materials, you must choose the high-standard prototyping tool.

- Available resources: Even if you’re willing to buy a premium prototyping machine, your budget might not allow you to go for it. So keep in mind your budget before selecting a rapid prototyping tool.

Which prototyping tool should you buy?

Buying a right prototyping tool depends on the above-listed factors. But is there any special machine that could give you the optimum results and within a short period? Be it Selective Laser Sintering device, DMLS, Fuse Deposition Modeling, or CNC machinery, every tool comes with its own pros and limitations. But when it comes to the most precise prototyping tools in recent times, you can expect a quality output from the Computer Numeric Controlled Machine (CNC). It can cut, shape, notch, and design all types of material rapidly.

Congratulations @jamesdean1! You have completed the following achievement on the Steem blockchain and have been rewarded with new badge(s) :

Click here to view your Board

If you no longer want to receive notifications, reply to this comment with the word

STOPDownvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit