A Complete Guide to Reaming Tools

Introduction

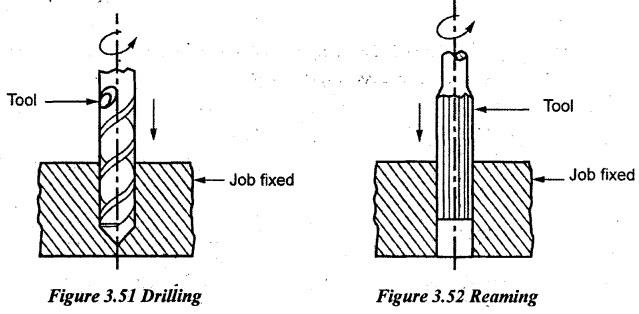

A reaming tool is a precision machining tool used to enlarge and smooth out holes that have already been drilled or bored. It provides a higher degree of accuracy and a better surface finish, making it essential in many industries, including automotive, aerospace, and manufacturing.

- What is a Reaming Tool?

Reamers are cylindrical tools with multiple cutting edges that slightly enlarge the hole’s diameter and improve its accuracy. The reaming process removes a minimal amount of material, typically less than a millimeter, and is used to achieve precise hole dimensions and a smoother finish.

Types of Reamers

• Hand Reamer: Used manually with a tap wrench for light reaming work, providing precision by the operator’s hand force.

• Machine Reamer: Designed for use with machines like lathes or drill presses, offering faster and more precise hole finishing.

• Adjustable Reamer: The blades on these can be adjusted to ream holes of varying sizes, adding versatility.

• Tapered Reamer: Used to ream holes that have a slight taper, common in fitting components like pins or bushings.Applications of Reaming Tools

• Metalworking: Reamers are used to refine holes for bolts, pins, and other fittings.

• Automotive Industry: Critical for ensuring the precision of engine components, such as valve guides and connecting rods.

• Manufacturing: Helps in the production of machinery parts that require highly accurate holes, such as in gear production or molds.Advantages of Reaming

• Improved Accuracy: Reaming ensures tight tolerances and uniform hole sizes.

• Smoother Surface Finish: Provides a high-quality finish to the walls of the hole, reducing friction and improving the fit of mechanical parts.

• Efficiency: Reaming can save time by reducing the need for multiple machining passes to achieve precise dimensions.How to Use a Reaming Tool

• Preparation: Start by drilling a hole slightly smaller than the final required size.

• Reaming Process: Insert the reamer into the hole using slow, steady pressure. Avoid forcing the tool, as this can damage both the reamer and the workpiece.

• Machine Setup: Ensure your machine settings, such as speed and feed rate, are adjusted to match the material you’re working with.Maintenance and Care

• Sharpening: Reamers should be regularly sharpened to maintain their cutting performance.

• Cleaning: After each use, clean the tool to remove debris and chips, which can cause wear.

• Proper Storage: Store in a dry, secure location to prevent damage and corrosion.

Conclusion

Reaming tools are essential for achieving precision in various machining applications, offering tighter tolerances and smoother surface finishes than standard drilling. Whether used manually or with machines, reamers provide a reliable way to ensure accuracy in hole dimensions across multiple industries.

What are your go-to reaming techniques or challenges? Share them in the comments! 💬

#ReamingTools #PrecisionMachining #Metalworking #Manufacturing #DIY