Two important factors in developing a SSD are the NAND Flash and controller IC. However, rapid advances in technology means that memory and IC quality require additional checks. In response to this, ADATA Technology Co., Ltd. has developed its A+ Testing Methodology, resulting in the most rigorous testing process. Testing for flash memory is divided into two major processes: 1) Flash evaluation is conducted at the start of the flash memory, followed by back-end 2) IC validation to ensure that all products are of the best quality.

ADATA's professional A+ Testing Methodology not only provides a major boost to production yields but also delivers quality products.

Flash Evaluation

ADATA has developed testing methods and standards based on Joint Electron Device Engineering Council (JEDEC) guidelines targeted at three critical attributes: Retention, Endurance and Cross Temperature. These ensure that flash memory meets product specifications.

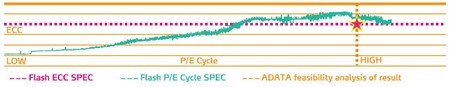

Endurance Testing

Large quantities of product samples undergo extended read, write and erase testing. The Bit Error Rate (BER) of each round is also verified to validate Flash memory endurance. This test can be used to confirm the life of the Flash memory and provides the best guarantee of quality.

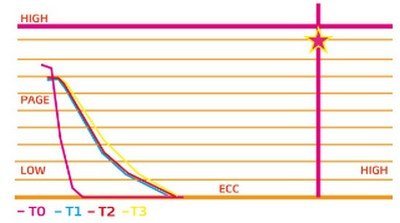

Retention Testing

After the samples undergo endurance testing, the Flash is fully written and the BER observed at different points in time at high temperatures. This test provides an effective way of determining product data retention over long periods of time and an early evaluation of its applications.

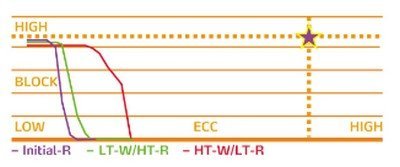

Cross Temperature Testing

Cross temperature operation is usually a key factor for Flash memory, especially for operation in high-stress environments – for example industrial PCs, or systems requiring exposure to harsh elements. Through cross temperature read-writes as well as observation of BER, any performance problems under extreme environments can be identified.

IC Validation

ADATA has developed its own hardware and firmware tests for IC Validation. More exacting testing standards are set at every point so the final product will be up to even higher standards. For industrial control, ADATA has defined even more stringent cross temperature tests. All components must undergo a series of tests before finally being manufactured in products that meet customer requirements.

- Go here for a full listing of ADATA SSDs – and make certain the one you purchase is TRIM-enabled.

- Go here to access ADATA's free SSD ToolBox software.

- For those of you who need an extra measure of protection for the data on your SSDs, check out ADATA's flawless Power Loss Protection feature.