This is the technique and tool that is used by our minting team for our coins dies and for the last 2017 Steem Silver Round.

This is the pantograph machine, we'll give it a little intro.

Essentially it's kind of like a key cutting machine and record player in one, but not really since it also scales the size of the reproduction. This probably doesn't make a whole lot of sense so let me let Wikipedia explain it.

A pantograph (Greek roots παντ- "all, every" and γραφ- "to write", from their original use for copying writing) is a mechanical linkage connected in a manner based on parallelograms so that the movement of one pen, in tracing an image, produces identical movements in a second pen. If a line drawing is traced by the first point, an identical, enlarged, or miniaturized copy will be drawn by a pen fixed to the other. Using the same principle, different kinds of pantographs are used for other forms of duplication in areas such as sculpture, minting, engraving and milling.

Did that help? Or make it worse

It's just the fancy machine that takes the large epoxy mold of the art and carves it into a coin die, we're about to get much more into it.

This is the large epoxy mold of the final coin design, it is created by taking an impression of a plaster that is hand carved by a sculptor.

This is then reproduced to the much smaller coin die.

When the machine is activated it spins and reads the first pattern then cutting it into to whatever smaller scale is being used of the coin die. It has a series of pulleys, gears, tensionors and motors that detemine the speed of spin, depth of cut and reproduced size. This same machine and same plaster can be used to create a die as large as 64mm for a 5 ounce silver round to as small as 8mm for a 1 gram gold round. This process can take up to several days of spinning on the pantograph and takes a master's touch and lots of technical expertise to ensure the heads are mounted, sharpened, adjusted and chosen just right.

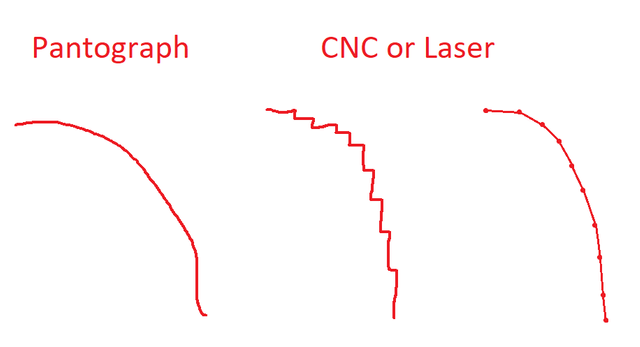

Most of these pantograph machines are very old and new ones are no longer constructed since most have been replaced with CNC machines or laser engravers, although most of the big government mints are still using pantograph machines to create there coin dies. This was a topic of discussion with our minting team and they provided use with some great insight. Although these new machines are highly sophisticated, when they are programmed using the 3d vector files it's never a fluid as the human sculptor who makes the plaster used as the template(more on this step in another post). It was explained that when a master sculptor carves the plaster the lines and contours are created fluidly and perfectly and the pantograph is the only way to replicate that onto the die. When the computer follows the rounded surfaces it break it down into a series of way points. In earlier machines this left a stepped pattern of cuts, this has improved and it not connects dots to a series or way points, but it never really follows the same fluid movement a human is able to create.

I used all my sweet graphic design skills to make this little image to try and explain it, they was it was explained to us.

Interestingly I noticed this exact same phenomenon when I zoned in on my awesome artwork above.

I found this video on YouTube of one actually in action, but otherwise from my understanding, there are not many pantographs remaining in operation and public hands.

Really cool. I never thought a lot about how coin dies are made. Very interesting.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Great article/post.

Why the big sizes? Is it just to check detail?

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

The big size for the initial epoxy? Some guy carves that think by hand. It would be damn hard to carve all those details at like 1.5"

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Haha makes sense. I thought machine was enlarging not reducing.

I see the point now

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

I have always wondered. I have a large copy router in storage and that is called a pantograph but it only does 1:1 scale, so not technically a pantograph at all. I haven't got the 3 phase to run it yet as it is big and will make Four reproductions at a time. I prefer the old machines they were made really well and do generally give better results. I have been fascinated by the art work of coins , it is seriously impressive.

Thanks

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

That's pretty cool you have something similar for your woodworking. I do agree that there something just more real and true about some of these older machines and technology.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

I have a bit of a passion for old machines and tools. Strong, easy to repair and accurate. I would love to see some more about the original sculpting of the coin if you could point me in the right direction please?

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Good post. Thanks for sharing

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Sweet Man! 2018 Steemit rounds are around the corner too! Gonna be a good year 😀

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Oh yea, can't wait.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

I was wondering why CNC and computer design wasn't used for this. I'm surprised that it still has that much error in it. I see what you're talking about in your drawing, but from what I've seen on a laser cutter you'll never notice those "imperfections", but maybe since coins are so small those imperfections will make a bigger deal?

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Yeah, It may just be the "old school" mint makers talking, but I'd love to see a comparison of the laser engraved vs pantograph die.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

If you ever get a chance to compare this I'd love to see it.

I'm sure there is some truth to their "madness", but wonder if those "imperfections" from lasers could even be detected by the human eye.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Please upvote me

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

I think as a kid I had a similar toy. Long time ago. It came with plastic designs/example drawings that you could enlarge on paper. But it was all too wobbly.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Yeah, I see the one in the Gif, I've been tempted to try to build one for my kids.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

You have received an upvote from STAX. Thanks for being a member of the #steemsilvergold community and opting in (if you wish to be removed please follow the link). Please continue to support each other in this great community. To learn more about the #steemsilvergold community and STAX, check this out.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thank you for sharing this information with us. We all love to collect the coins, but we often don't know exactly how they are made. The time and skill that are needed just to make the molds, makes every coin that much more special.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Yeah, It was super cool touring the mint and getting to ask these questions and see the process.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

This was incredibly interesting!! Do they make dies with laser engravers now, or is it more CNC?

I'm hoping to get 1 or the other later in the year if the planets all align.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Yes they do use both laser and CNC, but I still think many mints are reluctant to abandon the pantograph for the "true " feel.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Awesome post! I love old machines. Especially ones that are not being produced anymore. I have no doubt that there is an art to running those correctly. I could watch those "How Its Made" videos for hours.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Oh yea, I'm a huge fan of "How It's made" so cool to know what happens behind the sceens.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Cool stuff @phelimint! I was aware of the process, but have never actually seen a pantograph.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit