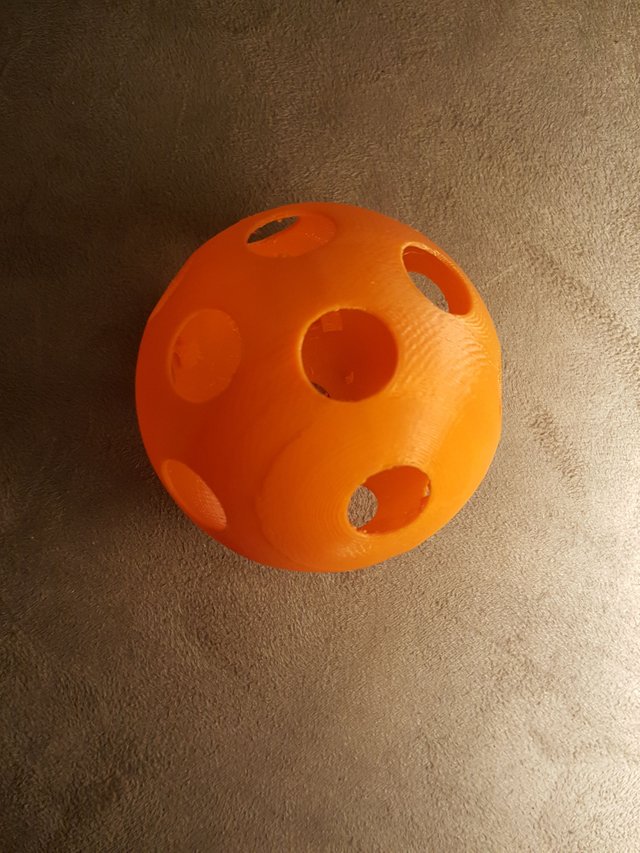

I'm still at the very beginning of the journey to 3D print a working pickleball, but I have produced my first prototype. The goal of this project will be to eventually produce the best pickleball possible from a consumer 3D printer (I will try the formlabs as well in the future, ).

The first iteration I went with more of an indoor style with large holes, to make it easy to get support material out and just for an easy design. My final ball should be a 40 hole outdoor style ball.

This was printed on a Makerbot Replicator 2, with the original print head, and Makerbot PLA filament. The thickness was 1 millimeter, and overall diameter was 2.95".

The print came out pretty well, but the functionality was terrible. It cracked on the first drop, that is what can be seen in the pictures.

The improvements for next time will be thicker walls, and an attempt at annealing (a process in which you heat the part and then slowly cool it, which can strengthen 3D printed parts), and maybe also coating in an epoxy.

Any other suggestions to try? I also want to try ABS and nylon in the future, but I have to wait until my Prusa 3D printer comes in the next couple months to attempt that.

Congratulations @how2s101! You received a personal award!

Click here to view your Board

Do not miss the last post from @steemitboard:

Vote for @Steemitboard as a witness and get one more award and increased upvotes!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Congratulations @how2s101! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Do not miss the last post from @steemitboard:

Vote for @Steemitboard as a witness to get one more award and increased upvotes!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit