Vacuum insulating

glass is mainly used in building envelope and industrial products (such

as freezer

doors, car and ship windows, etc.), and has to

withstand the repeated effects of sunlight and high and low temperature changes

during its lifetime. Te time to maintain its good performance is the key to the

survival and development of vacuum glass as an industrial product.

Vacuum glass is different from laminated glass or insulated glass that contain organic

materials:

- Laminated glass contain PVB or SGP interlayer,during its

lifetime,rain/temperature and humidity will affect the interlayer and

cause bubbles around glass edge,or delamination problem after years. - Insulating glass contains butyl and silicon sealant, the rubble

or sealant will aged and decrease its lifetime after years as well,IGU max

lifetime is 25 years. - Tempered

glass has no lifetime as well,it can work if only glass don’t break.

Different from above

normal architectural glass,vacuum glazing ,whether it’s sealed by glass solders

or metals,the glass component are inorganic materials, every component,whether

it’s sealing materials,glass itself,won’t get oxidized or aging after

years,so vacuum glass can serve 25-50 years.

The so-called

“vacuum glass lifetime” refers to the time that the high vacuum degree (≤0.1

Pa) in the vacuum insulating glass can be maintained.The main factors that

cause the working vacuum to drop are:

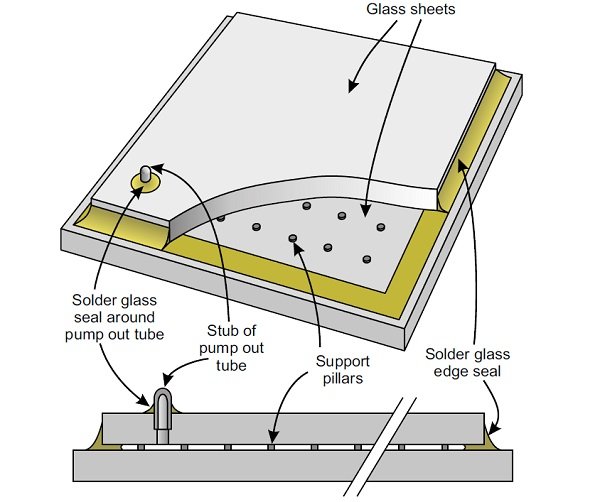

1.Leakage.

The periphery of the vacuum glass are sealed with low-melting glass powder

widely used in the kinescope industry.

The application practice for more than 80 years has proved that (the

black-and-white TV came out in 1939, and the color TV came out in 1953): this

sealing material is enough to meet the needs of Sealing requirements for

various electric vacuum devices such as tubes (the allowable leak rate of

electric vacuum devices is ≤10-12 Pa·m3/s).

2.

Gas The main

factors affecting the life of vacuum glass The glass surface and body contain a

large amount of gas. These gases are dissolved or adsorbed on the surface

during glass melting or thermal processing, about 102 Pa·L/cm3. Under the

action of external conditions such as temperature and light, these gases can be

desorbed from the glass surface,or diffused into the vacuum layer.

Heating and baking are the main methods of degassing glass in the electric

vacuum industry.Of course in our vacuum glass production,the sealing

temperature is 250℃-350℃,under this high

temperature the gas were removed from glass surface and inside and keep high

vacuum degree.

3.Getters.

In order to ensure the service life of the vacuum glass lifetime≥ 20 years, in

addition to the above measures, a long-term getter has been installed in the

vacuum glass to further improve the vacuum degree of the vacuum glass. The

application practice of electric vacuum devices represented by picture tubes

can prove that vacuum glass is a reliable and long-life static vacuum device.

Vacuum insulating glass produced by HaanGlas can reach 50 years,and offer

up to 10 years warranty.

While be careful when handling,installing,and

avoid damage before installation.

HaanGlas is your turnkey vacuum glazing

manufacturer and supply,kindly contact us for your next great project.

Contact us:

Location: 501,Sweetome,NO.2

Dongyue Ave,Taian city,Shandong Province,China

Mail: [email protected]

Website: https://www.vacuum-glass.com/vacuum-glass-solutions/

Mobile: + 86 17705464660