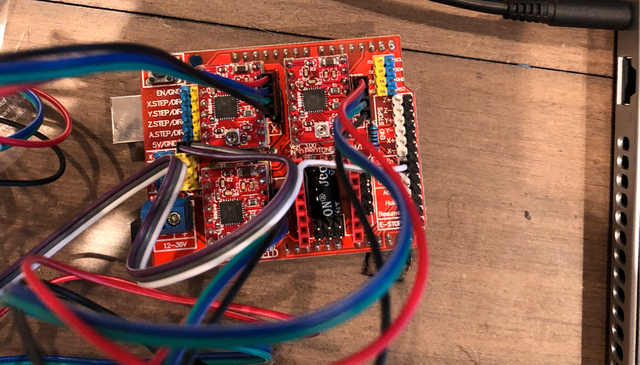

I was building my new tiny, tiny CNC mill and discovered a problem.

Everything was working apart from the spindle.

As you can imagine, that was a little irritating as the spindle is kinda important to the whole operation.

Turned out after some arduino tinkering, the shield has the wrong pin connections.

You see, it seems around version 0.9 the Spindle PWM pin had a change.

My GRBL firmware was sending PWM to pin 11. The shield pin though was NOT connected to that pin.

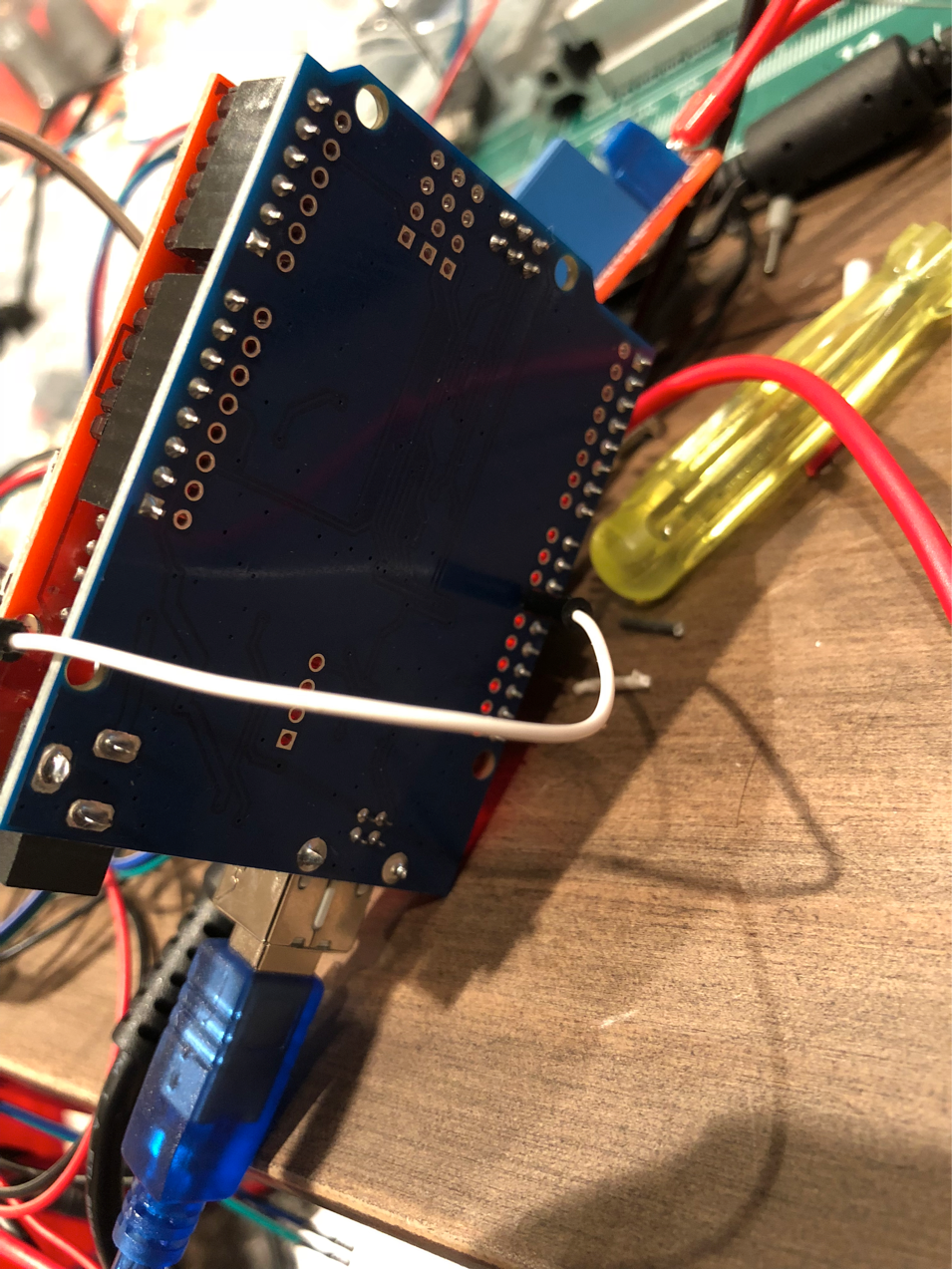

Thankfully, with a little Arduino search I can change the pin allocation, or I can just solder the pin directly.

Lesson here though - hardware dependent on certain pin allocations causes obsolescence problems. Not sure how many customers would have been completely stymied with this issue. Especially considering this particular CNC kit comes with zero instructions ...

Hopefully, the pin location did not fry anything. What is the purpose of this CNC: engraving and cutting small stuff ?

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Yeah PCB and stuff but because it’s built out of extrusion I’m thinking it would scale up nicely

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Cool.

For the extrusion you are using 2020, 3030 or the biffy 4545 ?

I am thinking about putting external TB6600 stepper drivers to put reliably 2A in my stepper motors, do you have any experience with those ? I found a set of 5 for less than 30 $.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

I have a bunch of 2020 here so likely use that. Not tried those stepper drivers :)

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Ciencia ,tecnology,memoria ,creativity,ideas ,logica ,creo que es mucho

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit