Supply chain is a very big topic, and it can be found in almost any industry. For enterprises, how to manage supply chain seems to be a constant problem for a long time.

For an industry, how to provide the best configuration strategy of the supply chain from the perspective of the industry as a whole is also a constant problem.

So when the supply chain meets the blockchain, some of the excellent characteristics of the blockchain can just solve the problems in the current supply chain field.

What’s Supply Chain

Before talking about blockchain and supply chain, you need to understand what supply chain is. Although the supply chain also has something to do with the chain, it is actually a network-like structure.

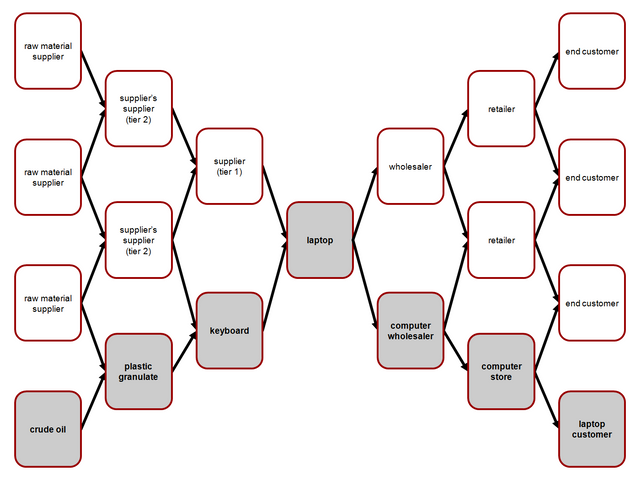

The following figure shows the various links in the notebook computer supply chain.

The picture shows the manufacturing process of the laptop. The left side shows the raw material supply side for manufacturing a laptop computer, and the right side of the “laptop” shows the demand side which contains multiple roles such as wholesalers and retailers. The multiple roles combines together and forms the supply chains built around laptops.

From the above diagram, let's summarize what is a supply chain. The supply chain is built around core enterprises and products. It is a network chain structure that starts with suppliers, passes manufacturers, transporters, distributors, and ends with consumers.

Supply Chain Field

The supply chain field is divided into supply chain management and supply chain finance. Let’s start with supply chain management.

- Supply Chain Management

Supply chain management refers to various activities and processes that plan, coordinate, operate, control, and optimize the entire supply chain system. The goal is to minimize the total cost of this process. It should be noted that the total cost here refers to the smallest total cost of the enterprises involved in the entire supply chain, not the smallest cost of a single link.

The supply chain involves the roles of supplier, manufacturer, channel vendors, and so on, which was connected by a series of transactions such as purchasing, inventory, logistics and so on. Purchasing, inventory, and logistics are mainly around warehousing, distribution centers, and logistics transportation, so we can also consider the supply chain as a network of suppliers, manufacturers, channel vendors, warehouses, distribution centers, and logistics transportation.

In this network, the biggest problem between the various roles is the issue of trust, because only by establishing trust can those roles collaborate to complete the process of product manufacturing and sales. The first problem facing supply chain management is how to reduce the cost of trust and form a loosely-trusted chain structure of mutual trust. Each role must coordinate its own and external resources through effective on-chain management to meet market demand.

There are three flow processes: information flow, logistics, and capital flow.

1)Information flow: It means that each role needs to understand and track the current position and status of the product in the supply chain.

2)Logistics: It refers to the process by which products or raw materials are transferred to the target role.

3)Capital flow: It refers to the process of settlement of upstream and downstream funds.

The current status of the supply chain is that capital flows, information flows, and logistics operate independently. Capital flows rely on banks, information flows depend on supply chain management tools, and logistics depend on the transportation industry. They all revolve around one or more core enterprises. Therefore, each role is extremely dependent on the core enterprise. This model exposes the following issues:

- Core companies have limited reach and control over upstream and downstream in the chain;

- Upstream and downstream roles may have the risk of fraud and tampering of information flow due to competition.

- Changes in market supply and demand cannot be transmitted to the supply side in time, and the risks from market demand to supply side are sequentially amplified.

These problems will increase the complexity of the supply chain management of core companies and lead to the ignorance of risk caused by the weak participation of non-core companies. Although a series of tools have appeared in the market to help improve the upstream and downstream collaboration capabilities of the supply chain, there are still some problems.

There are many different parties involved throughout the supply chain. Because different participants may use different databases or even paper documents, it is difficult to integrate data across systems.

The data in the traditional database system has the risk of being tampered with and attacked. There is still much room for improvement in accuracy and safety.

Due to the difficulty of tracking products, once a problem occurs in a certain link, the regulatory agency has certain difficulties in investigating, obtaining evidence and accountability for non-compliant activities.

In other words, as long as the centralized thinking remains the same, but the form has changed, it is still difficult for traditional technology to effectively solve the problem. However, the transparency and sharing between peer and peer and tamper-resistant features of blockchain are almost the cure for the supply chain. Therefore, blockchain is also known as the ultimate weapon of supply chain management.

- Supply Chain Finance

Supply chain finance and supply chain are two concepts. Supply chain finance belongs to the category of finance and it serves the supply chain.

Supply chain finance (SCF) can refer to a variety of financing instruments, which can be used to provide funds to all parties in the supply chain, using short-term credit to balance the liquidity gap between upstream and downstream, so as to minimize the total supply chain costs. Companies can also use supply chain financing to build stronger relationships with suppliers, reduce financial risks and increase liquidity.

Like other finances, the core of supply chain finance is also risk management. The premise of good risk management is the truthful, reliable, transparent sharing of supply chain information. Traditional supply chain finance revolves around banks. Banks' collection of supply chain information is also constrained by the traditional technologies, making it difficult to record the actual order info between enterprises. Therefore, risk control relies heavily on the reputation of the enterprise.

Therefore, if all participants can truly and accurately check the processes and status of the entire supply chain, then risk management becomes a shared part of the entire supply chain participants, not just the core enterprises and banks.

Blockchain Technology Leads the Future of the Supply Chain

Blockchain has brought major changes in thinking to the supply chain. It is no longer an ecosystem built around core companies, but an ecosystem of co-governance. Blockchain as an infrastructure can provide participants with a credible environment and reduce the cost of the supply chain.

We know that there are three flows in the supply chain: logistics, information flow, and capital flow. The ideal situation is actually "three streams in one", that is, blockchain provide the basic manage system for the three streams. Here is an explanation.

The blockchain itself can also provide information registration, for example, the order status can be formatted as a blockchain transaction additional content.

Blockchain is applied to the flow of funds. You must think of digital assets. In fact, after being registered, items can also be viewed as certificate with value. The verification and delivery of the items or products can be regarded as another form of digital assets.

The application of blockchain to logistics may be completed in conjunction with IoT technology. Because as a distributed system, blockchain technology cannot directly sense the status of logistics, such as the temperature of food during transit. Those data collected from products using sensors needs to be uploaded to the blockchain, or to be registered to the blockchain after hash processing. In fact, it is very difficult to achieve "three flows and one" in the supply chain at this stage, but it’s a trend, which depends on the development speed of the blockchain.

Therefore, the entry point of the blockchain in the supply chain is often logistics, because it’s the most obvious that logistics can be combined with the blockchain technology. Starting from logistics can avoid direct competition with existing supply chain tools. For example, existing supply chain management tools have provided information flow management, and banks have provided capital flow management. Therefore, it is most likely that the project will start from logistics.

In logistics, the blockchain can guarantee the authenticity and credibility of data registration, open and transparent information to all participants, and provide product traceability.

The main focus is on the cross-border logistics environment. The key point of cross-border logistics also involve the impact of customs, cross-border exchange rates, and destination country policies. The degree of mutual trust is lower, so cross-border logistics is addressed. It is a breakthrough point of the blockchain in the supply chain.

There are also many well-known cases of blockchain application in the supply chain, such as the several cases often mentioned in the industry:

- Maersk and IBM's marine insurance blockchain platform;

- Wal-Mart uses blockchain to track food traceability;

- Zhongan's blockchain chicken farm records and traces the entire chicken growth process in real time;

- HNA's end-to-end virtual reality information flow platform based on blockchain technology.

In fact, through careful analysis, we can find that the above organizations use DLT technology, that is, the alliance chain, not the public chain.