Introduction to PCB Boards

PCB boards, also known as circuit boards, are essential components in modern electronics. They provide a platform for connecting and supporting electronic components, enabling the smooth operation of various devices and systems. In this blog post, we will explore the key aspects of PCB boards, including buying tips, design and assembly, choosing the right board, the manufacturing process, and prototyping techniques.

Buying Circuit Boards Online

A. Researching Reliable Suppliers

When buying circuit boards online, it's crucial to research and find reliable suppliers. Look for companies with a good reputation, extensive experience, and positive customer reviews. Check if they comply with industry standards and offer quality assurance.If you want to buy PCB boards then you can visit https://robomart.com/bread-board-and-zero-pcb for best price with premium quality.

B. Comparing Prices and Specifications

Before making a purchase, compare prices and specifications from different suppliers. Consider factors such as board material, layer count, size, and additional features. Balance your budget with the required specifications to get the best value for your money.

C. Reading Reviews and Testimonials

Take the time to read reviews and testimonials from other customers who have bought circuit boards from the supplier. Look for feedback on the quality, delivery times, customer support, and overall satisfaction. These insights can help you make an informed decision.

Understanding PCB Board Design and Assembly

A. PCB Layers and Materials

Learn about the different PCB layer configurations and materials available. Understand the impact of layer count on the complexity and performance of your circuit board. Consider factors such as signal integrity, power requirements, and thermal management when selecting the appropriate materials.

B. Schematic Design and Layout

Familiarize yourself with the schematic design and layout process. Use design software to create the circuit diagram and optimize the component placement for efficient signal flow. Pay attention to factors like trace length, impedance control, and ground planes to ensure reliable performance.

C. Component Placement and Soldering

Master the art of component placement and soldering. Follow industry best practices for component spacing, orientation, and thermal considerations. Use the appropriate soldering techniques, tools, and materials to achieve secure and reliable connections.

Choosing the Right PCB Board for Your Project

A. Identifying Project Requirements

Begin by identifying the specific requirements of your project. Consider factors such as the intended application, environmental conditions, power requirements, and anticipated lifespan. This will help you narrow down the options and select a board that meets your needs.

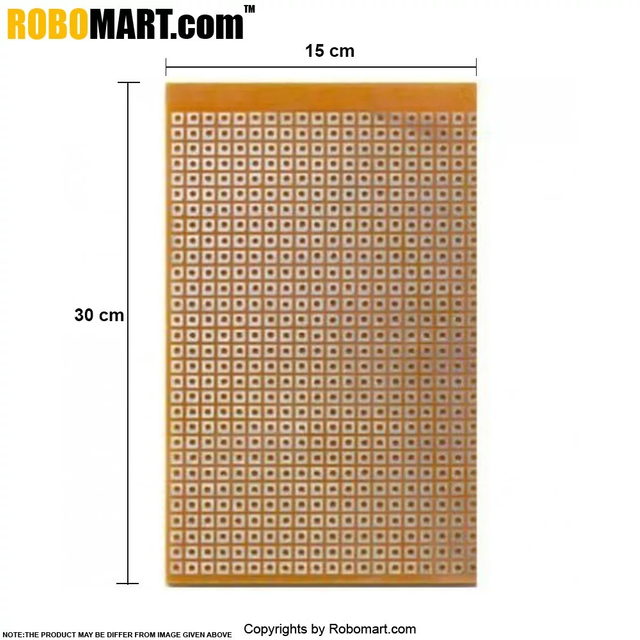

B. Size, Shape, and Mounting Options

Evaluate the size, shape, and mounting options of the PCB board. Ensure it fits within the available space in your device or system. Consider the mounting method (e.g., through-hole or surface mount) based on your assembly process and requirements.

C. Considering Signal Integrity and Power Requirements

Pay close attention to signal integrity and power requirements. Analyze the impedance control, power plane distribution, and noise considerations. Ensure that the selected PCB board can handle the required voltage levels and provide stable power delivery.

Exploring the PCB Manufacturing Process

A. PCB Fabrication

Understand the PCB fabrication process, including the manufacturing steps involved. Learn about the preparation of the substrate, application of the copper layers, etching, and drilling processes. Gain insights into the technologies and techniques used to produce high-quality PCB boards.

B. PCB Assembly

Explore the PCB assembly process, which involves attaching electronic components to the fabricated board. Learn about surface mount technology (SMT), through-hole technology (THT), and the equipment used for precise component placement, soldering, and inspection.

C. Quality Control and Testing

Discover the importance of quality control and testing in PCB manufacturing. Explore the various tests performed, such as visual inspection, electrical testing, and functional testing. Understand the quality standards and certifications that ensure reliable and defect-free PCB boards.

Prototyping a Circuit Board

A. Creating a Prototype Design

Learn the steps involved in creating a prototype design. Use prototyping software or breadboarding techniques to translate your circuit schematic into a physical prototype layout. Optimize the design iteratively based on testing and feedback.

B. Component Selection and Ordering

Carefully select the components for your prototype. Consider factors like availability, cost, and compatibility with the PCB board. Order the required components from reliable suppliers to ensure timely delivery.

C. Assembling and Testing the Prototype

Assemble the prototype by soldering the components onto the PCB board. Follow proper soldering techniques and pay attention to component orientation and polarity. Test the prototype for functionality, identify any issues, and make necessary adjustments before moving to production.

Conclusion

In conclusion, understanding PCB boards is essential for anyone involved in electronics projects. By following the guidelines provided in this blog post, you can make informed decisions when buying circuit boards, designing and assembling PCBs, choosing the right board for your project.