Introduction

Building a robot is an easier process than it was in the past. All that is needed is to take into account some of the basics of robotics.

Basic Concepts

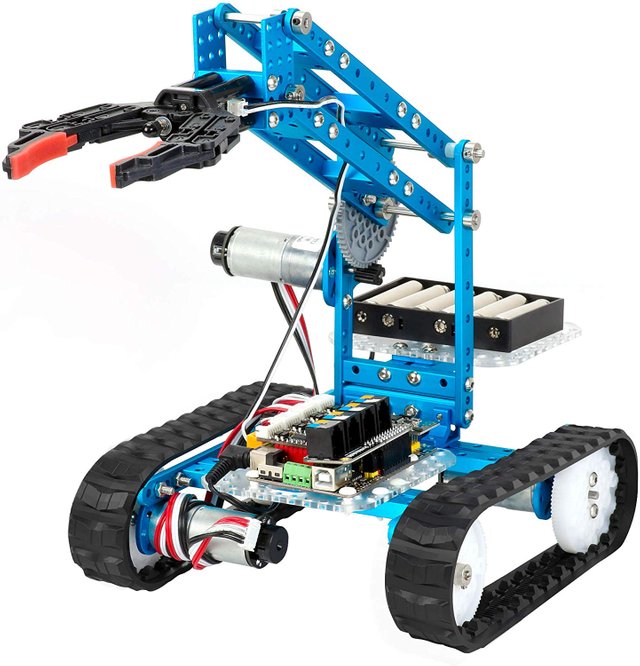

Image Source: https://www.amazon.com/

Although robotics are more accessible than ever, any robot is a complex system and requires a basic understanding of electricity, mechanical design and programming. This article will guide you through the elements of robotics, custom robot design considerations, what it takes to start building a robot and design ideas to spark your creativity.

These days, amateur manufacturers and engineering companies are building endless types of robots. And the capabilities of these robots are growing exponentially.

The MIT Cheetah 3 robot can now jump and gallop across rugged terrain, climb a ladder full of debris and quickly regain balance when suddenly pushed. All while essentially blind.

The 90-pound mechanical beast (about the size of an adult Labrador) is intentionally designed to do all this without relying on external environmental cameras or sensors. Instead, he quickly "feels" his way through his surroundings in a way that engineers describe as "blind locomotion," much like breaking through a completely dark room.

In order to build or assemble robot kits for adults yourself, the basic concepts discussed below must be taken into account. If you want the best resource to advanced robot kits; then check out this ultimate guide to robot kits on Sunglass.io.

Mechanisms

Image Source: https://www.amazon.com/

Making robots move is a crucial part of robotic design. This is where design mechanisms, or mechanical engineering, come into play. While mechanical engineering is more about machine design, robot designers will focus specifically on motors and gears, and how to best use them to get the desired movement of their robots.

This generally involves prototyping individual moving parts before attempting to assemble the entire robot, but it can be as simple as adding wheels to a DC motor. The level of complexity depends on the type of intention of the robot and the way in which the robot will move.

Electronics

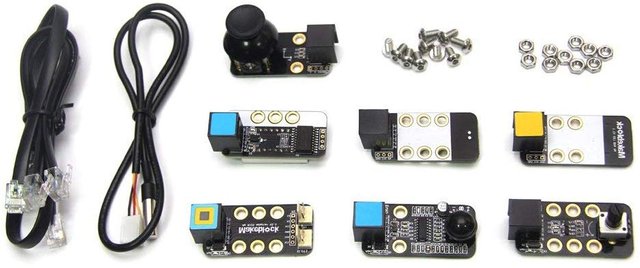

Image Source: https://www.amazon.com/

Another fundamental part required to build robots is circuit design, also known as electronics. The understanding of electronics and microcontrollers will allow you to make the right decisions regarding motors, components and power for the robot that is being designed. It also considers the functionality and physicality of its parts.

A basic understanding of the circuits allows engineers to build a simple robot (such as an RC car) with much online support, documentation and kits available. It may seem an intimidating part of the project, but fortunately easy guides of basic electronics have been created for these purposes.

Programming

Once you have an electrically solid circuit and mechanisms ready to move, it is time to program the microcontrollers used in the circuit. The microcontroller is the brain of the robot, which needs instructions to know how to act and / or react to the surrounding world.

For example, a distance sensing robot needs to be told how to take data from its distance sensor and how to use this data to function. Similarly, an RC car needs to know which joystick buttons initiate forward movement in front of backward movement in front of turns.

The chosen microcontroller will determine the programming language used and how that program is loaded into the microcontroller. An Arduino-based robot uses the Arduino programming language and can be loaded through the Arduino IDE. A micro bit robot uses the visual learning language make: code and is loaded through a drop in desktop files. A robot based on Raspberry Pi uses the python language, which can be programmed directly through the chip when connected to a monitor and keyboard.

Manufacturing

Manufacturing is the final step in the construction of a robot, where the components are joined in the lining for the robot. With the development of accessible digital manufacturing tools, such as laser cutters, CNC mills and 3D printers, amateur robot designers can make refined models that look professional, without the high overhead costs of major manufacturing operations.

The design of the robot cover and the materials chosen depend on what type of robot is being manufactured and the purpose it serves. While the cabinets are practical to extend the mechanisms and protect the precious electronics inside, engineers can also use other models to give the robot personality, express the desired interaction and provide information on how to use the robot.

Other Considerations

Environment

Will the robot move and, if so, on what type of terrain will it navigate? Do you have to dust or water? The exterior elements do not come into play so much if the bot will be kept safe from the elements at home. But imagine where the robot will go and how much environmental abuse it must endure. This affects your choice of materials, the design of the robot mechanisms and the general cover.

Energy

Will you choose the freedom of the batteries or can you live with your robot attached to a wall for energy? Each motor, sensor, processor, etc. It needs a certain amount of energy, so you must determine how much energy each component will consume and how long you want the robot to be operational in order to take into account the energy requirements in the overall design.

It may seem trivial, but choosing the right type of power system is one of the most restrictive aspects of the robot's design. As such, it is smart to first consider the power system before designing any electronics project. And always remember to choose electronic parts that are rated for the power system used and vice versa.

Body and Materials

How much will the robot weigh? Will the ice cream sticks work or do you need custom machined aluminum? Are there practical fixing points for sensors? How safe is the battery? The robot body can be as simple or complex as you want, but the best robot designs allow flexibility, which facilitates an agile process of prototyping and construction.