I have working on motorcycle, scooters, and atvs for 18 years. This blog is years worth of notes all put together into this blog. This blog should answer a lot of your questions on how to tune a carburetor. This will cover how they work, the carburetor components, and tuning tips with illustrations

Basics of a carburetor:

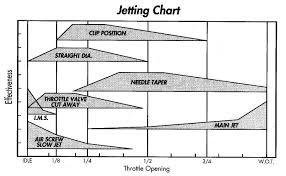

The carburetor consists of four components:

Pilot Jet - this controls the amount of fuel when idling

Main Jet - this controls the fuel when you open up the throttle (between 50 and 100 percent power)

Jet Needle - this controls the fuel when you open and close the throttle (between 20 and 80 percent power)

Needle Jet - this is what the jet needle pops in and out of (between 15 to 60 percent of throttle

Main jet tuning: perfect air fuel ratio is 12.5-1

Denver formula for 70 degrees at 5300 feet is : 0.948

Here is a table made from the formula: the temperature and altitude with give you the correct atmospheric pressure, the numbers below have been pre calculated.

T = 20 40 60 80 100F

0ft 1.056 1.033 1.011. .989. .967

3000ft 1.025 1.003. .981. .959. .937

5000ft 1.008 .985 .963 .941 .919

8000ft .985 .962 .940 .918 .896

12000ft. .961 .938 .916 .894 .872

Take 0.948 x jet size = new jet size

This will give you a good place to start. At this point you can do a plug chop to verify jetting. Be sure you are full throttle under load for at leased 200 yards or so. Up hill works best.

Pilot jet tuning:

If the motor is back firing at decel this is a good indication the pilot jet is to lean. Try richening up the fuel mixture by turning the fuel screw out or the air screw in to allow more fuel. Any more than 3 turns out go one size larger on the pilot jet. Fuel screws are towards the front of the carburetor and air screws are toward the rear of the carburetor. 2-2.5 turns out on a fuel screw is proper for Colorado. In most cases screw adjustments won't correct the lean back firing, installing a one size larger pilot jet will do the trick for higher elevations (Colorado).

How to determine the proper jet size on a Chinese scooter:

Carburetor diameter(12mm) x 5 = 60(or number it calculates) x 0.9 = sea level jet size

For Denver:

Take 0.948(Denver atmospheric pressure at 70 degrees) x jet size(60) = new jet size(56.88) round up 57 would be the proper jet size to start at for a stock scooter using a 12mm carburetor.

EXTRA EXAMPLE:

Great little jetting article:

(this is a good article we found on the net)

CF = function(temperature,altitude)

the CF is correction factor. CF=1 for sea level, 70 degrees F. If it is 80 F at 5000 ft, you calculate a new CF, say 0.9 (this is just an example). You take your main jet that is for a CF=1, say a 200. Multiply 200 by the CF=.9 to get 180 as the new main jet. This gives you a good place to start your fine tuning.

Needles are a little trickier, I think each needle clip was worth a change in CF of 0.1 on my KX. Probably about the same on the YZ426F, I am one clip leaner here in Denver, which is about CF=0.9, depending on temperature. You can also use it for pilots, but pilots sometimes go the other way (larger at high altitude). You need to determine this by pilot screw position. If not running (idling around 1k RPM) optimally between 1/2 and 2 1/2 turns out, change the pilot. Another way is by backfiring on a YZF on decel, too lean. Richen up by turning pilot (fuel) screw out. If you go more than 2 1/2 turns to get rid of backfiring, change the pilot richer (bigger).

I have the formula at home, I will get it and post it. I made it into a table and pasted it on the inside of my toolbox lid. Remember, its a good place to start but is not the same as jetting by someone who is good at it. For example humidity can affect jetting and the formula does not include this).

Jetting formula (cf x jet size = new jet size)

CF = 1.0778-.00111T + (2.3855410^-10)A^2 -(1.077710^-5)*A

T is temperature in degrees F

A is altitude in feet

If you plug in A=0 and T=70 you get CF=1. This is your correction factor at standard temperature and pressure (STP). If you put in 5000 ft and 70 F (Denver), you get CF=.95. So your bike that was jetted for a 175 at STP now requires a 0.95 * 175 = 166 (or the nearest size).

Here is a table made from the formula:

T = 20 40 60 80 100F

0ft 1.056 1.033 1.011 .989 .967

3000ft 1.025 1.003 .981 .959 .937

5000ft 1.008 .985 .963 .941 .919

8000ft .985 .962 .940 .918 .896

12000ft .961 .938 .916 .894 .872

So lets say you take your bike and put on a new pipe, airbox, and such and get it jetted well in Denver on a 60 degree day (CF=.963). Lets say the main jet that runs best is a 180. Your new STP main jet is a 180/.963 = 187. If you go to sea level to race on a 70 degree day this is what you should try first. If you go up to ride at Rampart Range, 8000 ft on a 80 degree day, your CF=.918. So you should try a 187 * .918= 172. (You need to use the STP jet size as the base).

Needle clips are about a 0.05 CF change, from my notes. (I would like feedback if you find it different). You can use it for pilot jet sizes too, but don't be surprised if it doesn't work as well as the main. You need to fiddle with the slow circuit more.