Habedere everyone,

today I show you some work on the piping.

If you missed the 6th part (Plexiglass); here it is:

Project: Casemod - Hardware@Wall - Plexiglass and "My Mod-Highlight"

The multi-skin sheets are a key element in the whole mod. Many components are influenced by this parts.

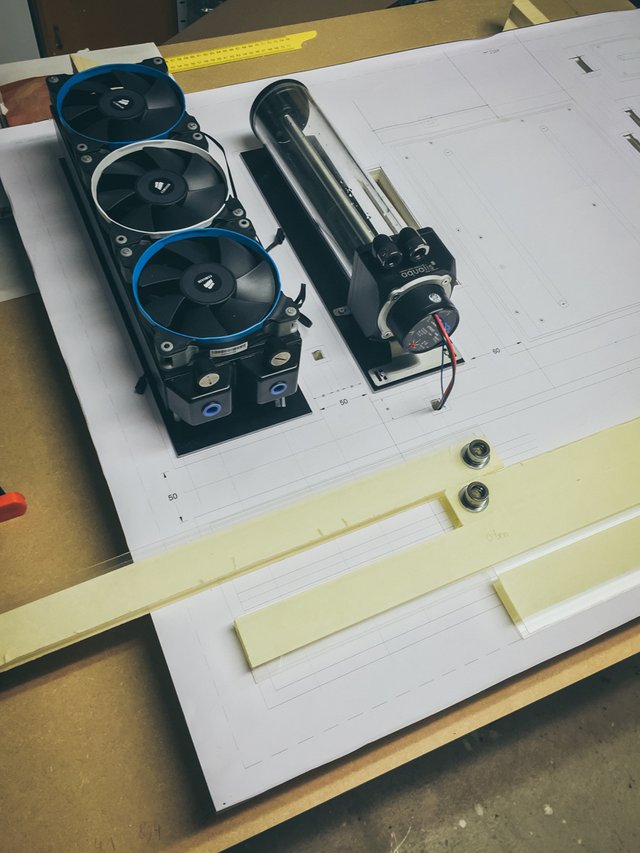

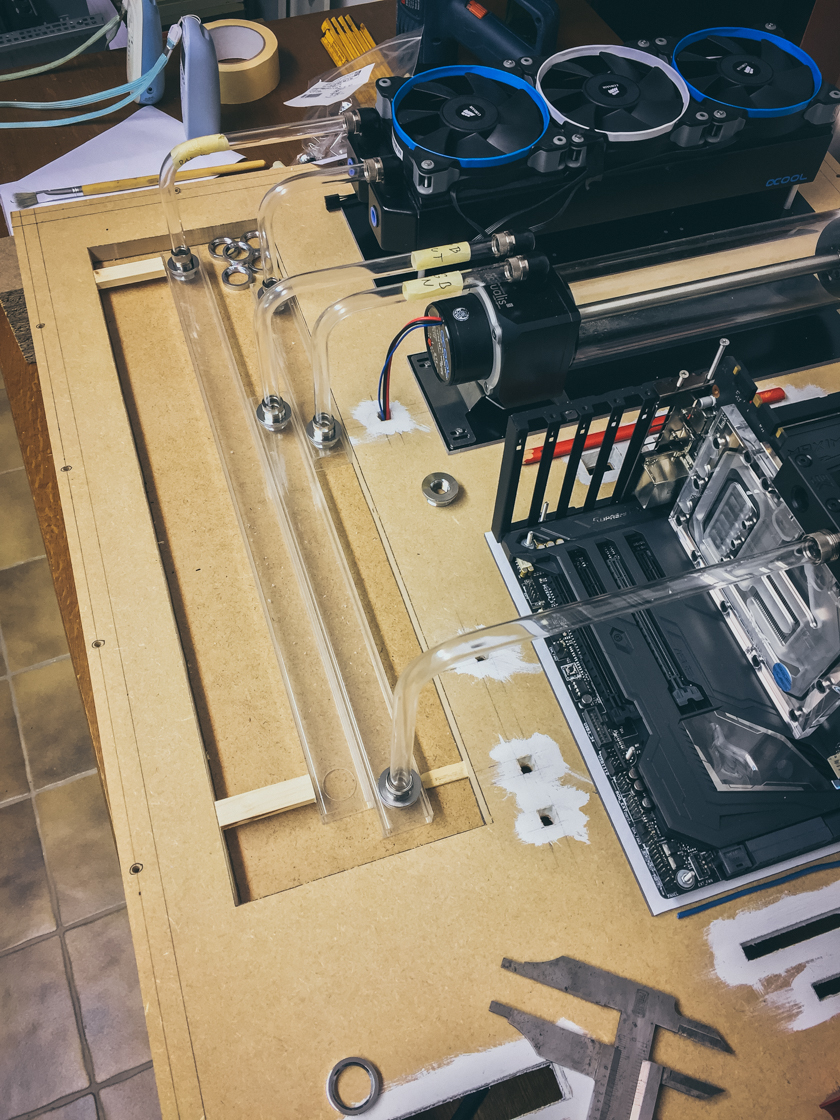

To move on I have to place all water cooling hardware before.

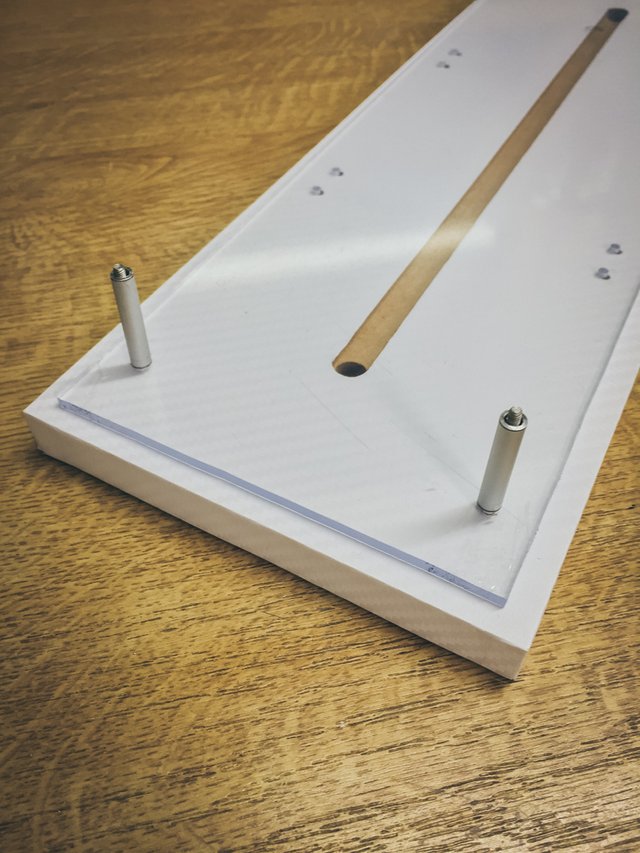

The components will be mounted on their plexiglass base. Mainboard and radiator will have some aluminum spacers in between.

Later I will paint the spacers black.

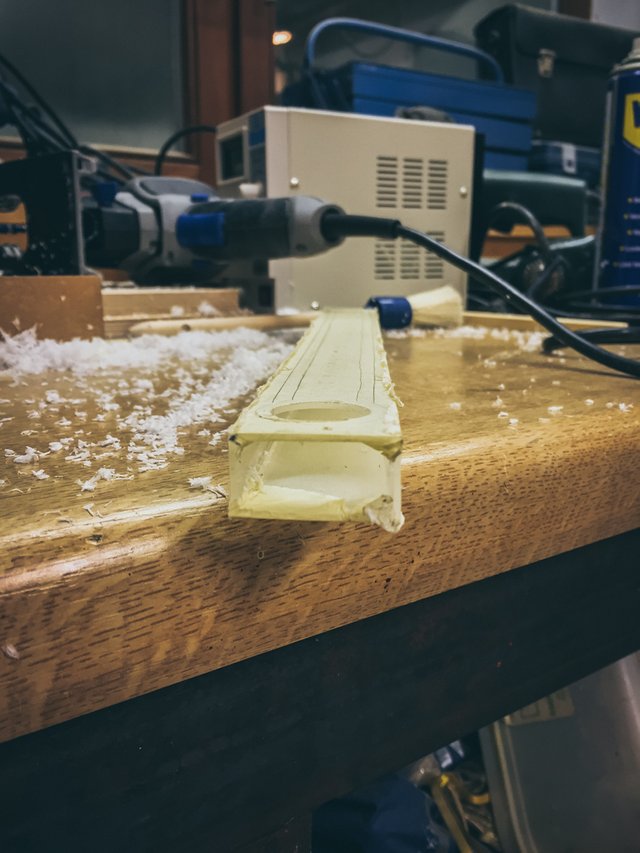

Here is an prototype example where I tested everything.

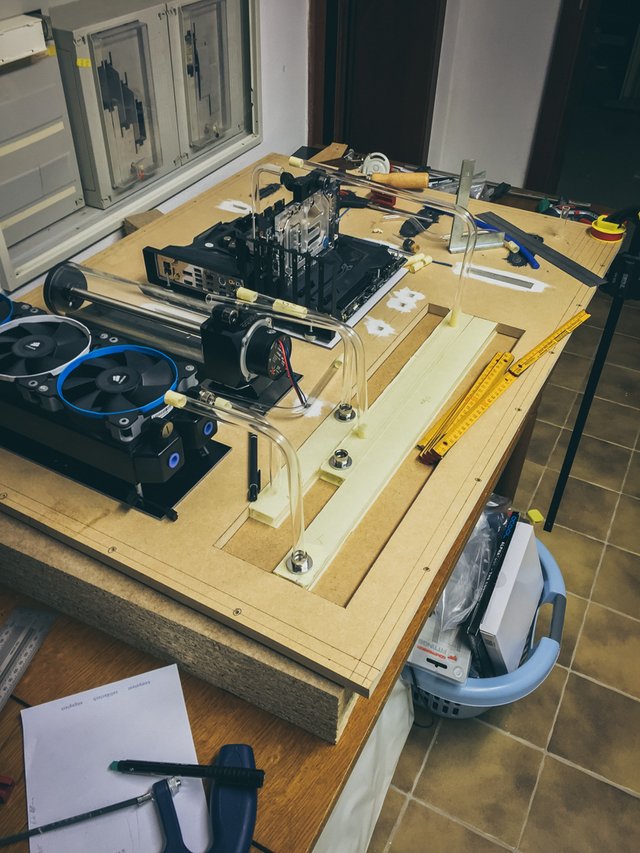

With the help of my CAD document and a lot of measuring I placed the multi-skin sheets to the right position. Then I cut and moved them to their final position.

There is enough room for 4 multi-skin sheets, but I only need 3.

In the free area I will install some kind of lighting.

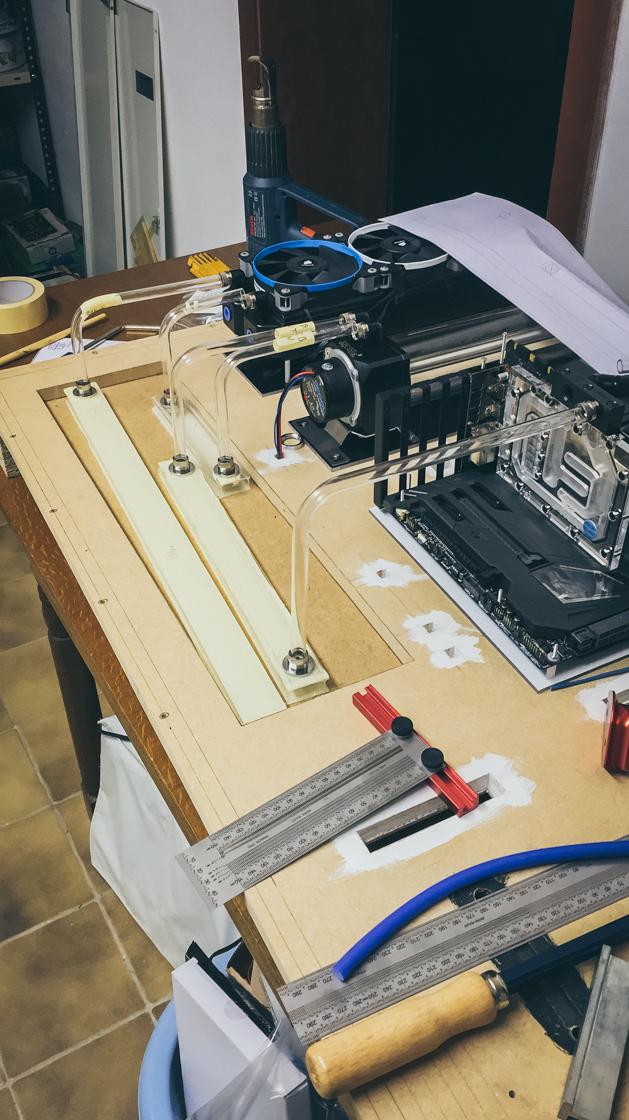

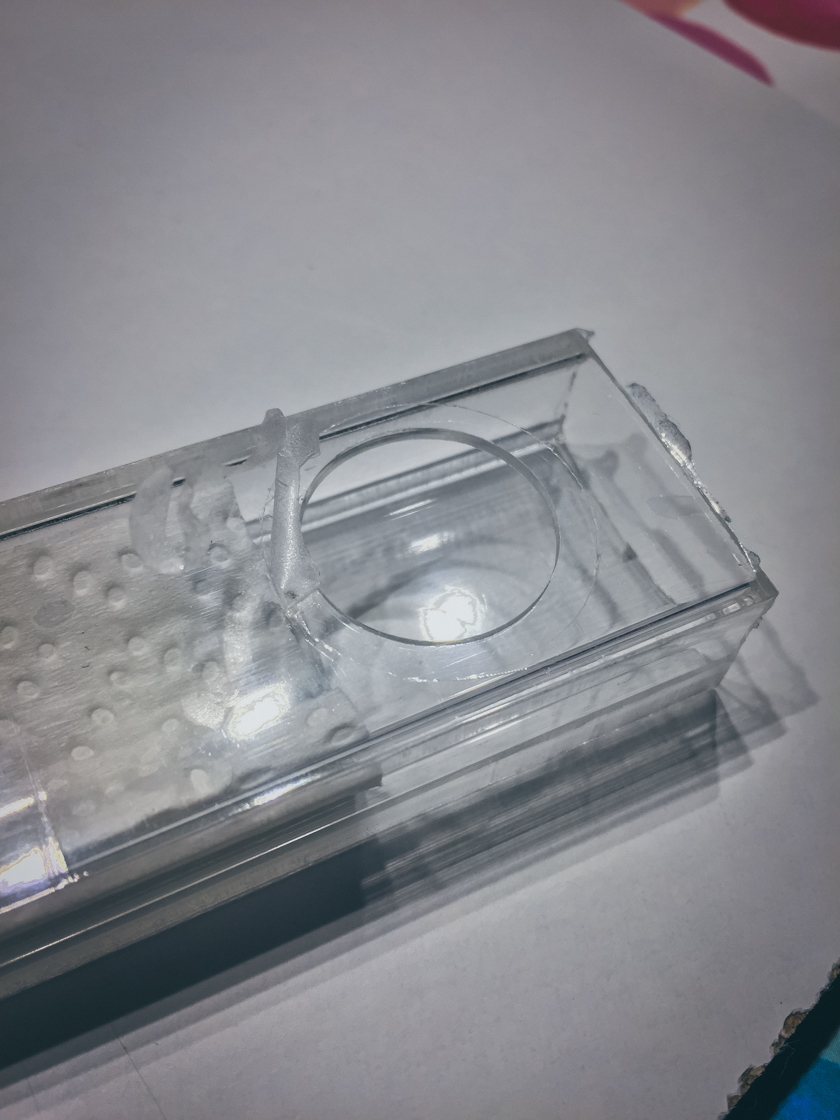

On one side I started with the holes for the fillports.

Here it is with the EK Fitting.

On the other side I had to start with the piping, because I was too difficult to measure.

I have used 12mm hardtube

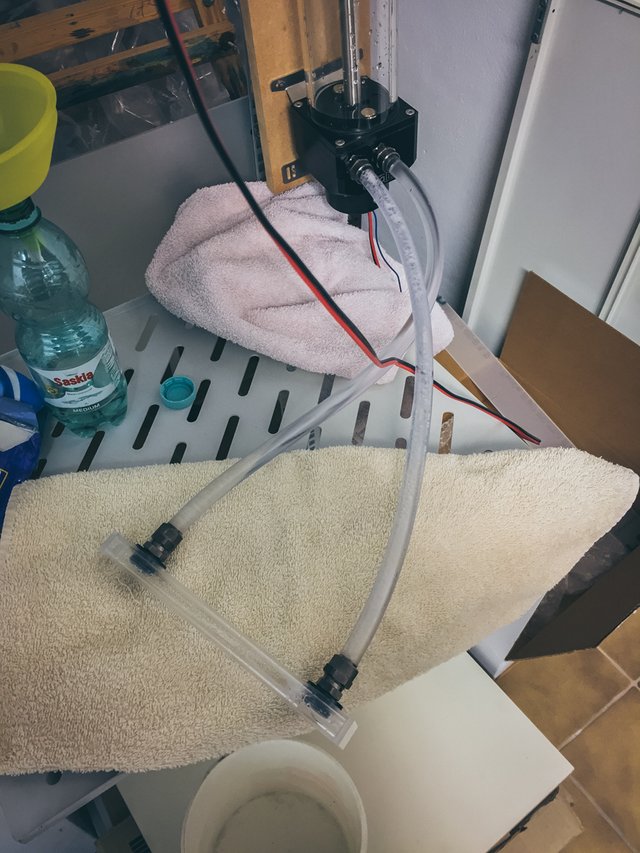

My saw- and bending station. :)

On the hardware side I installed 90 degree fittings from Alphacool

After all pipes were bend I could start to drill the holes for the second fillport.

I used my router to reduce the distance between the multi-skin sheets . After that the profiles laid directly next to each other.

I sanded and painted the fillports so that they will fit optically to the rest of the mod.

During my prototype I was very wasteful with the glue.

Accordingly the result looked very awful. Glue everywhere.

I didn't want that in the final version of the profile.

So I masked the area with some tape.

Then I glued everything together.

Filports and the cover left and right.

To be honest I had a very bad feeling during this process.

"This will never work".

I didn't want to use as much glue as on the prototype.

First test with water => everything tight.

Next, Profile 2 and 3

....untight. Fuck.

Source: giphy

Not on the side, but underneath the fillports.

Seen from a distance not really a surprise.

I want to glue metal to a 1mm plexiglass.

And this should be tight? Nice try.

Lessons learned. Now I have to try another concept.

What's next?

While I’m thinking of a new concept I work on the MDF panel.

Servus and cu next time.