The chicken feed manufacturing plant is normally made use of to produce various sort of chicken feed pellets, such as infant chicken feed pellets, laying chicken feed pellets, chickens feed pellets, as well as griddle feed pellets. The working procedure is generally precleaning, crushing, blending, pelletizing, cooling down, screening along with packaging.

The related cases are: Animal Feed Factory Project In Saudi Arabia

The gadgets of the precleaning location are drum kind precleaner, powder filter, along with long-term magnet sleeve. This section is to eliminate contaminations such as rope, paper, rocks, and likewise iron filings mixed in the raw items. After being cleansed, the raw materials are sent out to the precrushing container by the pail lift. Raw items go into the feed mill tools. The feed grinder machine is squashing the raw materials right into powder which is convenient for the succeeding treatments. After that, the powder is sent out to the feed mixer equipment. The feed mixer device is for the blood circulation uniformly of basic materials and additionally other ingredients. All the materials get in the poultry feed pellet machine. The chicken feed pellet tools is a vital manufacturer in the manufacturing of feed pellets. In pelletizing area, the items, with conditioning, get in the pelletizing chamber. In the chamber, the powder is very squeezed by the ring die as well as the tension roller to develop pellets. To make the pellets save longer, they are sent out to the counterflow colder to readjust the temperature degree. After cooling down, the pellets can be loaded.

Being used the chicken feed pellet maker, you need to be attention to the following concepts.

- Chicken feed pellet tool along with furthermore its top magnet is called for to be regularly cleansed. If you do not clean, the iron in the feed inlet might enter into the ring die of the chicken feed pellet tools, which affects the regular working of the devices.

- The wear service of the ring pressure as well as die roller demand to be examined at well-known periods. The wear of the stress and anxiety roller could impact the production capability, which would affect the premium of pellets.

- Inspect the cutter of the chicken feed pellet machine. The cutter is used too candid, which would definitely lower the creating price of the feed pellets.

- When transforming raw materials, the cone container above the chicken feed pellet device and also the ended up thing container should certainly be entirely cleared to quit mixing.

This can increase starch pasting as well as lower the production of hazardous microorganisms. It furthermore can improve producing effectiveness as well as also pellet leading quality.

Pets need to eat nutritionally well balanced feed for a long time to obtain advantages, which are carefully relating to the operation of animal feed tools. Precisely exactly how can a chicken feed pellet device be far more durable? You need to take note of the list below variables.

- Do a terrific job in the trial run before the formal production. After the warmth treatment of the ring die, it ought to be examined whether the die opening is brightened or not, as well as whether the surface area of the die hole is adequate or otherwise.

- Relatively grasp the lots of the chicken feed pellet gadget. The whole lots degree of the animal feed devices has a fantastic impact on the result in addition to premium quality of the feed pellets.

- The dampness web material of products should certainly be handled. If the moisture product of the material is appropriate, the outcome along with top quality of the chicken feed pellet manufacturer can be increased. For the safe storage and also transportation of granular products, the moisture web content should be well managed.

Thus, prior to the chicken feed pellet devices is officially put into usage, the above aspects require to be completely examined. In the whole chicken feed factory, evaluation in addition to maintenance of the devices are needed before manufacturing to make sure the top quality of the pellets.

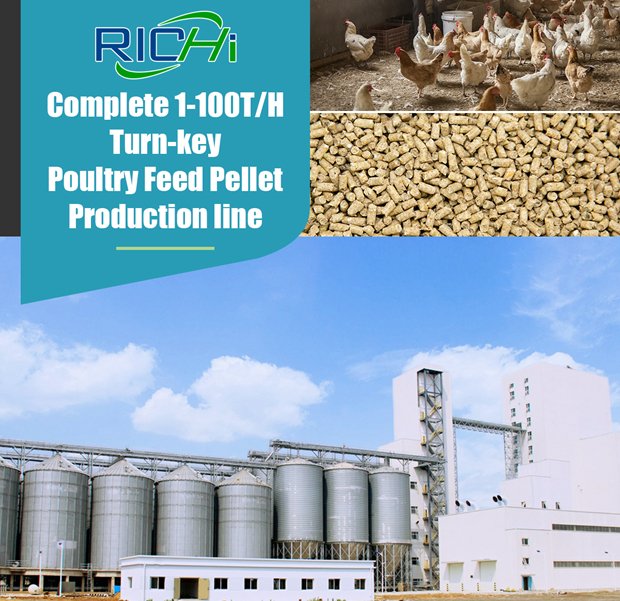

RICHI Machinery, situated in Zhengzhou, Henan Province, China, has really taken part in the manufacturing of pellet manufacturing equipment for more than 27 years. RICHI can supply you with various chicken feed manufacturing plants of 1-100t/h. RICHI Machinery additionally provides a one-stop service. It has a specialist system from architectural style, gadgets manufacturing, as well as installation to after-sales service.

More information is on the website: Poultry Feed Manufacturing Plant

Or you can contact:

Whatsapp: +86 18574103366

Email: [email protected]