Producing a print campaign and marketing materials across different print formats and processes with consistent colour can be a real challenge.

You could be dealing with offset, wide format display and signage, digital production print, even flexo for packaging! It will never be perfect but consistent colour is achievable throughout these print processes with effective colour management control.

Colour Management - How can it help?

Colour Management (CM) can mean different things to different people. Essentially CM is about how the colour is converted in a workflow (think RGB to CMYK) and how colour is managed with wide format and digital print and with digital proofing.

The colour on your phone, tablet or TV screen is RGB (Red, Green and Blue), compared to offset, wide format and digital print, which is CMYK (Cyan, Magenta, Yellow and Black). Your computer monitor may be calibrated for colour accuracy, which is a BIG plus, but it is still RGB.

TV and LED display screens are able to achieve very bright, vibrant and saturated colour compared to any form of traditional print. Therefore it is vital to keep this in mind when you are embarking with print marketing.

CM for print or colour quality management in print is about achieving colour consistency across the various media types and print processes used in your print marketing materials. If you are putting together a marketing campaign across the internet, TV and print it will be difficult to achieve perfect colour matching over these diverse forms of information, product and brand delivery.

However using best practice in CM can go a long way to achieving more acceptable, consistent and predictable colour from the design stage through to RGB display and CMYK.

Many of the big global brands are very well aware of this and as such they have well documented colour specifications for their brand colours for RGB and CMYK.

What is the key to Colour Management?

Well, first of all, remember that we dealing with two entirely different colour spaces - RGB and CMYK.

- RGB for ‘digital’ media (TV, computer screen, phone, tablet, large advertising display screen, etc)

- CMYK for print - ink on paper or plastic for offset and ink onto a core flute material or foam core board or self adhesive vinyl for wide format are good examples…

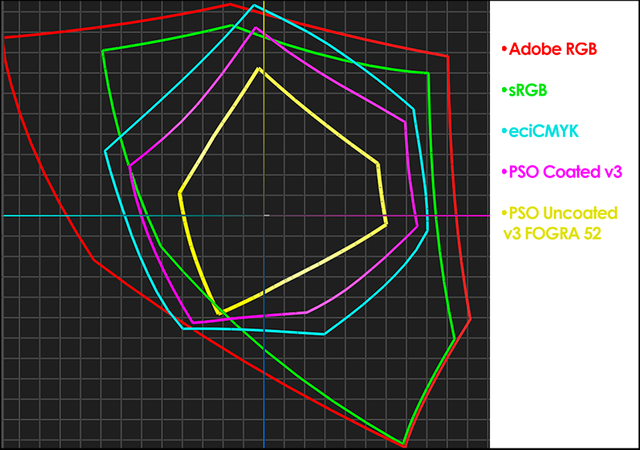

Now RGB is based on emissive technology - bright light on a LCD or LED screen. The screen is black when it is off, but when it is ON you are going to see very bright, vibrant and saturated colours, as we stated at the outset. This equates to a much larger and broader range of colours (or larger gamut) than is achievable in CMYK.

CMYK relies on the ‘paper’ or white substrate (white background) to reflect the available light which translates to a smaller or less saturated gamut.

This means your CMYK print campaign will not have the same colour saturation or vibrancy as your digital media campaign.

It is interesting to note that some of this can be managed by using custom or spot colours in print for particular brand colours.

And importantly CM is an enabling technology - e.g. it will allow you to simulate the printed result on your calibrated monitor!

My concepts and design are in RGB - What should I do?

The design and concept phase is almost always done in RGB. Why can’t they do it in CMYK? Well we do not live in a perfect world and we cannot always get what we want! Photographers and most design schools will work and teach you in RGB - this can mean that their skills and knowledge of CMYK is limited.

Many companies, packaging prepress houses and Ad agencies I work with are well versed RGB to CMYK conversion, but there is still a big gap with much of the creative work being done in RGB. Some companies will provide training or customer service staff to help with the CMYK conversion - even down to providing the Distiller preferences for the conversions.

Some print companies will accept RGB images and elements in the customer supplied files and look after the conversion at the prepress stage or in their work-flow or MIS system.

Quite often designers do not know how their designs and files will be used in print - i.e. Newsprint advert? Magazine? Packaging? Hence they are understandably reticent at designing or doing any form of conversion, as they are unsure about what ICC profile to use and convert to.

What CMYK ICC should I convert to?

- The key here is communication between the designer, the print buyer and the print company.

- When converting from RGB to CMYK it is best to convert to the largest CMYK space available - this then provides the necessary colour gamut for converting to smaller colour gamuts.

- There are ‘large’ CMYK profiles available for free download that provide a media neutral and print process neutral workflow.

To realise the full benefits of printer calibration and using a colour spectrophotometer please contact us at [email protected]

Congratulations @colourgraphic! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

The problem with various printing services is that they provide not very high-quality printing with poor color reproduction, but the prices are high. In order not to worry about the result, learn more about PrintSafari https://www.printsafari.com/us_en/brochures, which provides fast and high-quality printing of brochures and other printed materials with the possibility of customization.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit