The scarcity of protective equipment against coronavirus has caused companies and individuals to mobilize to deliver missing products to frontline professionals. In an initial phase, several 3D printing projects appeared to produce, for example, parts to hold the masks.

It was with this identified problem that we decided to do our part and start producing combs that are used to hold the elastics of the masks, which allows their pressure to stop happening in the ears.

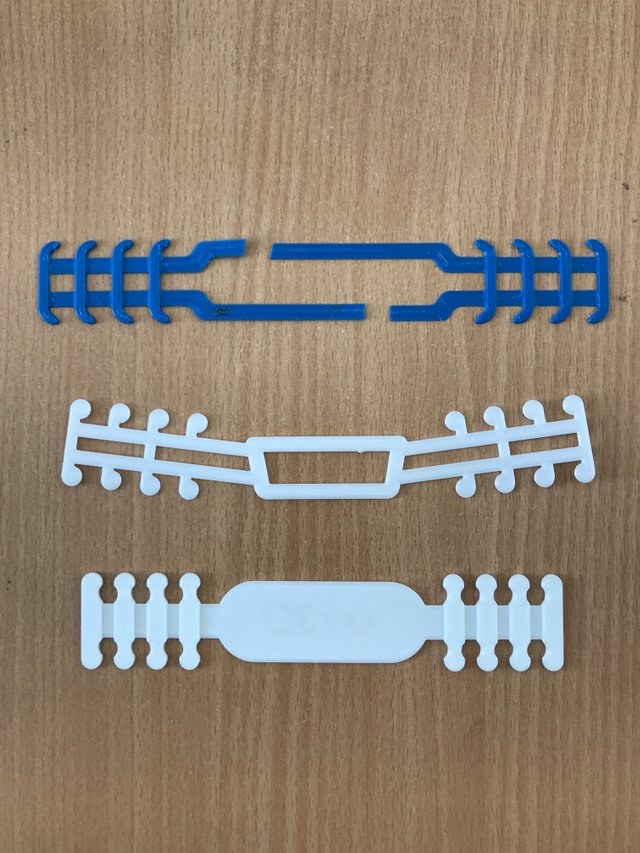

We identified several projects on the internet and several models as you can see in the figure here on the left. Some less robust but faster to execute, others more robust, but with more execution time.

We decided to opt for quality, producing the most robust. Each comb, produced individually, took about an hour. It was a lot of time. We then chose to remove the comb bed ("Raft") and slightly reduce its thickness. These changes made it possible to reduce the execution time to 30 minutes.

The printer started working 24 hours a day, seven days a week. The combs were delivered to the hospital and daily we received messages of thanks for this small relief that we allowed to give to our heroes in the fight against COVID.

It should be noted that during this period the price and delivery time of the PLA increased, but even so, we maintained our production by taking advantage of smaller pieces of PLA that were left over from other projects, hence the fact that some of the combs have different colors as can be seen in the figure on the left. Of course, even this change generated enthusiasm and discussion among the recipients of the combs because, as you would imagine, associations with the football club or the aesthetics and color combination with the combat suits to COVID started right away.

It is a project that we continue to execute and offer for free, this being our small contribution to this fight.