There are several types of sensors that could potentially be used for detecting 10 mm deep embedded cracks in a steel structure. Here are a few examples:

Ultrasonic sensors: These sensors use high-frequency sound waves to detect changes in the density or elasticity of material, which can indicate the presence of a crack.

Eddy current sensors: These sensors use electromagnetic induction to detect changes in the conductivity or permeability of material, which can also indicate the presence of a crack.

Magnetic flux leakage sensors: These sensors use magnetic fields to detect variations in the magnetic flux around a material, which can be caused by the presence of a crack.

Acoustic emission sensors: These sensors detect the high-frequency acoustic emissions generated by crack growth or other forms of material damage.

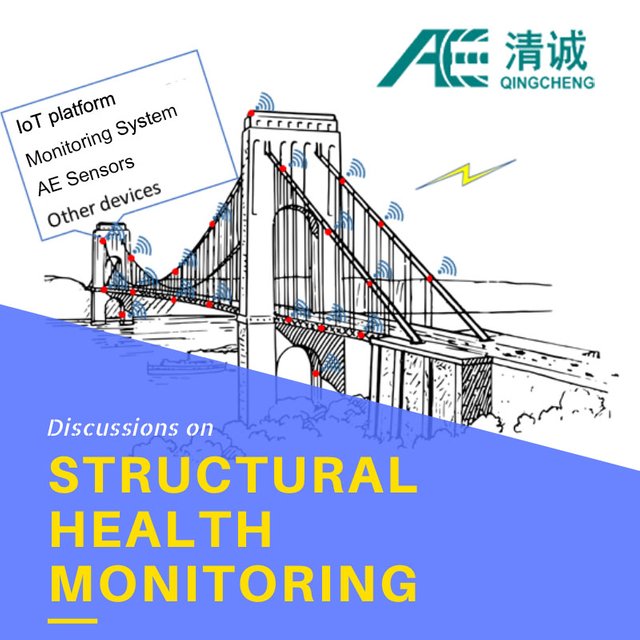

Out of these sensor types, AE sensors are particularly effective at detecting cracks and other forms of damage in metal structures. This is because they are designed to detect the elastic waves that are produced when a material undergoes deformation or fracture. When a crack grows or propagates, it generates a burst of these elastic waves, which can be detected by an AE sensor. AE sensors can be used to detect cracks that are not visible to the naked eye, making them ideal for inspecting embedded structures like steel beams or pipes. They can also be used to monitor the growth of existing cracks over time, allowing for preventative maintenance and repair. One company that specializes in AE products is QingCheng AE Institute. Their range of Acoustic Emission Sensor, Acoustic Emission Preamplifier, and online Real-time monitoring systems are designed to accurately monitor the health of metal structures such as pipelines, storage tanks, and bridges. They are easy to use and high cost-effective, making them a popular choice among engineers and maintenance professionals.

It's worth noting that the effectiveness of these sensors will depend on a variety of factors, including the size and location of the crack, the properties of the steel being inspected, and the specific sensor technology being used. In some cases, a combination of different sensors may be required to achieve optimal detection capabilities.