How can CPG Data Insights transform your supply chain: leverage the power of data for better demand forecasting to prevent out of stock, improve on-shelf availability and increase margins.

This is why your company needs CPG Data Insight for supply chain management

This is not an easy moment in time for supply chain managers. Geopolitical conflicts, inflation, the aftermath of the pandemic, and climate change are putting a lot of pressure on supply chain operations, and this situation will continue throughout 2023. Out of stock is becoming increasingly common due to disruption in the supply chain, and profits are suffering. So, how can companies strengthen their logistic systems and maximize on-shelf availability? The answer lies in their ability to leverage the power of CPG Data Insights for demand forecasting and supply chain optimization.

As reported by a Wtwco study, for 65% of businesses worldwide, the losses related to supply chain disruptions in the last two years were higher than expected. As a response, 58% plan to make significant supply chain changes in the near future.

Businesses are looking for a solution to transform their supply chain in order to optimize costs, avoid out of stock and ensure on-shelf availability. Advanced CPG data analysis provides executives with CPG Data Insights, which are extremely valuable to make data-driven decisions. Here are the steps to use CPG Data Insights to maximize on-shelf availability and take your supply chain to the next level.

Leverage CPG Data Insights for demand forecasting

Innovators are already using advanced AI software and state-of-the-art systems for demand forecasting, but the others aren’t quite there yet. With a staggering 73% of businesses still using spreadsheets as the main tool for scenario planning, the obsolescence of supply chains poses a serious risk in today’s challenging market.

Demand forecasting is one of the most crucial activities in supply chain management and presents a long list of benefits:

- Reduce risk

- Better allocate resources

- Avoid out of stock

- Increase operational efficiency

- Make better informed financial decisions

By collecting and analyzing both real-time and historical data, CPG Data Analytics identifies patterns, trends and potential issues, and accurately forecasts demand for scenario planning. This will allow you to adjust inventory levels accordingly to ensure on-shelf availability, avoid understocking and overstocking, and maximize revenue.

CPG Data Insights lead inventory management optimization, making sure that inventory levels are in line with demand patterns and lead times.

Make the switch to supply chain automatization

The consumer packaged goods industry is permeated with volatility, which makes it extremely difficult for companies to maintain the right inventory levels and minimize out of stock risk. Manually adjusting inventory is not efficient and often results in understocking or overstocking; moreover, it is susceptible to data loss.

The solution is automatization. Implementing automated replenishment systems helps streamline the ordering process by automatically generating purchase orders or replenishment requests based on both historical and real-time data. Ai-powered tools collect and analyze large amounts of data, centralize all processes in order to simplify supply chain management and generate CPG Data Insights for better demand forecasting.

Do you want to learn more about AI solutions for supply chain management? Here is how CPG data company Tredence successfully implemented automated replenishment for a leading global CPG manufacturer.

The importance of real-time data for on-shelf availability

Constant monitoring is crucial for every business activity, and supply chain management is no exception. Technology grants end-to-end visibility on all stages of the supply chain, and as measured by KPMG, this visibility enabled by real-time analytics helps maintain operational stability.

Regularly monitoring shelf conditions, fluctuations in demand, the emergence of new trends, changings in customer behavior and preferences, and SKU levels is extremely hard when done manually, but when automatized, it becomes an invaluable source of information. Monitoring systems identify issues like out-of-stock situations, allowing to intervene promptly to improve on-shelf availability.

Keeping data sources like sales records, point-of-sale systems, inventory levels and customer insights under constant monitoring provides CPG Data Insights that will help your company have a much clearer view of your entire supply chain.

How to avoid out of stock and increase margins

Executives worldwide are well aware of the challenges of today’s supply chains and their need to change logistic systems. But modern problems require modern solutions, and the answer to increasing complexity in the supply chain lies in the power of technology and consumer insights. Access to high-quality data, processing, and monitoring allows companies to overcome some of the biggest challenges in today’s scenario, like demand volatility, increasing costs, and low on-shelf availability.

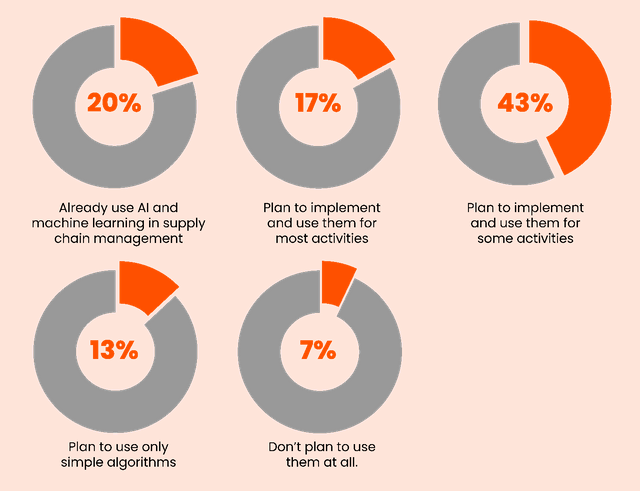

The benefits of CPG analytics are clear. Innovators are already paving the road, while others are still behind, but it is common knowledge that Consumer Data Analytics is the future of supply chains. McKinsey interviewed supply chain executives and found the following results:

- 20% already use AI and machine learning in supply chain management;

- 17% plan to implement and use them for most activities;

- 43% plan to implement and use them for some activities;

- 13% plan to use only simple algorithms;

- 7% don’t plan to use them at all.

Utilize advanced AI-powered algorithms to better understand your Consumer Data Insights and transform your supply chain to achieve more efficiency, flexibility, and resilience. Customer analytics consulting firms can help you transition toward the future.