[Social Talk] Company Town ① Toyota City (Japan)

Do you know that there is a city called Toyota City in Japan?

As you can see from the name Toyota, it is a city named after Toyota.

I would like to take a look at Toyota City in Japan, which is attracting attention as an industrial trading company city among various types of corporate cities.

A corporate city is a city that is leading a growth with private investment.

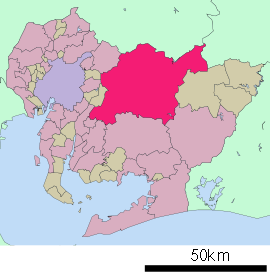

Located in Aichi Prefecture, about 30 km away from Nagoya City, the city is home to Toyota Motor Corporation's headquarters, seven assembly plants and Toyota Central Research Institute, and Toyota Tsusho University is also nearby.

Originally known as Komochirira, it was renamed Toyota City in 1959. In Aichi Prefecture, where Toyota City is located, Suzuki, a Mitsubishi automobile assembly plant, research institute, and light vehicle company, is located in Shizuoka, forming a sort of automotive industry cluster.

In this city, 12 affiliated parts companies called "Toyota Group" and more than 200 major auto parts suppliers supply products, facilities and logistics companies, as well as various automobile related companies such as general machinery, steel, And accelerate the development of the city.

Especially, Toyota's financial performance has increased since the performance of Toyota has increased. In 2003, Toyota City's product shipment nuclear power was 9.4 trillion yen, ranking first in Japan, and Toyota City's fiscal revenue It was 1.82 times the number one in Japan. On April 1, 2005, Nishikamo County, Fujioka County, Obama Rumah, etc. will be transferred to increase the population including interview.

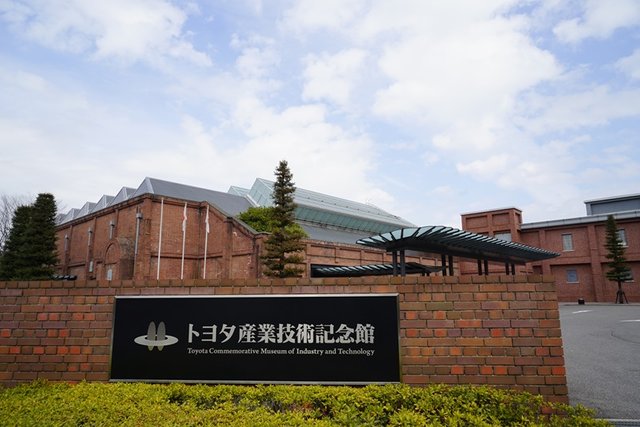

Prior to the change of name to Toyota City, Goromo City has grown historically as a textile industry. In 1938, when Toyota Motor was promoting the construction of its headquarters, it selected the location to prevent the damage caused by salt due to the level of steel making technology.

Since then, all 14 Toyota factories, except for Kyushu and Hokkaido factories, have been located in Aichi Prefecture. The farthest factory before the Kyushu factory was established in 1979, which is also a 1 hour 40 minute drive from Toyota headquarters. Minutes away.

Toyota's Just In Time (JIT) system has played a major role in this accumulation, which means that only a small amount of parts need to be supplied frequently, The result will be.

As a result, 80% of Toyota components companies are located in Aichi, 50% of which are located inside Toyota City. Secondary vendors are also in close proximity to this, which is why they have been in the 7th generation vendors.

Even when this Toyota city was made, there were twists and turns. At that time, the landlord demanded 30 won per pyong, but Toyota insisted 20 won. Toyota City, which saw this difference, saved the difference of 10 won to the city's budget, which was half the city's budget.

In 1965, Toyota City enforced the Factory Promotion Ordinance, and Toyota related companies actively moved to Toyota City. It seems that the policy of returning fixed asset tax and municipal tax to the incentive grant for three years from the commencement date of the project, and funding and tax benefit for the expansion and transfer of factories in the area played a major role.

In 1974, the SME financing grant system was implemented based on the Basic Law of Small and Medium Enterprises, and the grouping projects such as the Pungpyeong Ironworks Cooperative Cooperative and the Donghae Electronics Industry Cooperative Cooperative Union were developed.

CCC21 (Construction of Cost Competitiveness 21), which cuts the production cost of major parts by 30%, reducing the total cost by 10 trillion yen. It is said that the cooperation was made easier because the adjacent companies were able to exchange easily.

And this integration has formed a knowledge exchange network such as the cooperation meeting, the consultation of the production survey department, the research meeting, and the personnel exchange, and constituted the system as a whole which formed the complementary relation with the individual network function.

It is organized for the purpose of mutual friendship and governmental exchanges. The Production Research Department is based on the Toyota production method and resides in the partner company on a team basis for innovation. And consulting is provided free of charge.

The research group relocates its members every 3 to 5 years and consists of 5 to 8 component companies. Preliminary tests, diagnostics and experiments, presentations, follow-up surveys and assessments. Personnel exchange also helps exchange knowledge. Knowledge transfer and understanding of the problem at the same time.