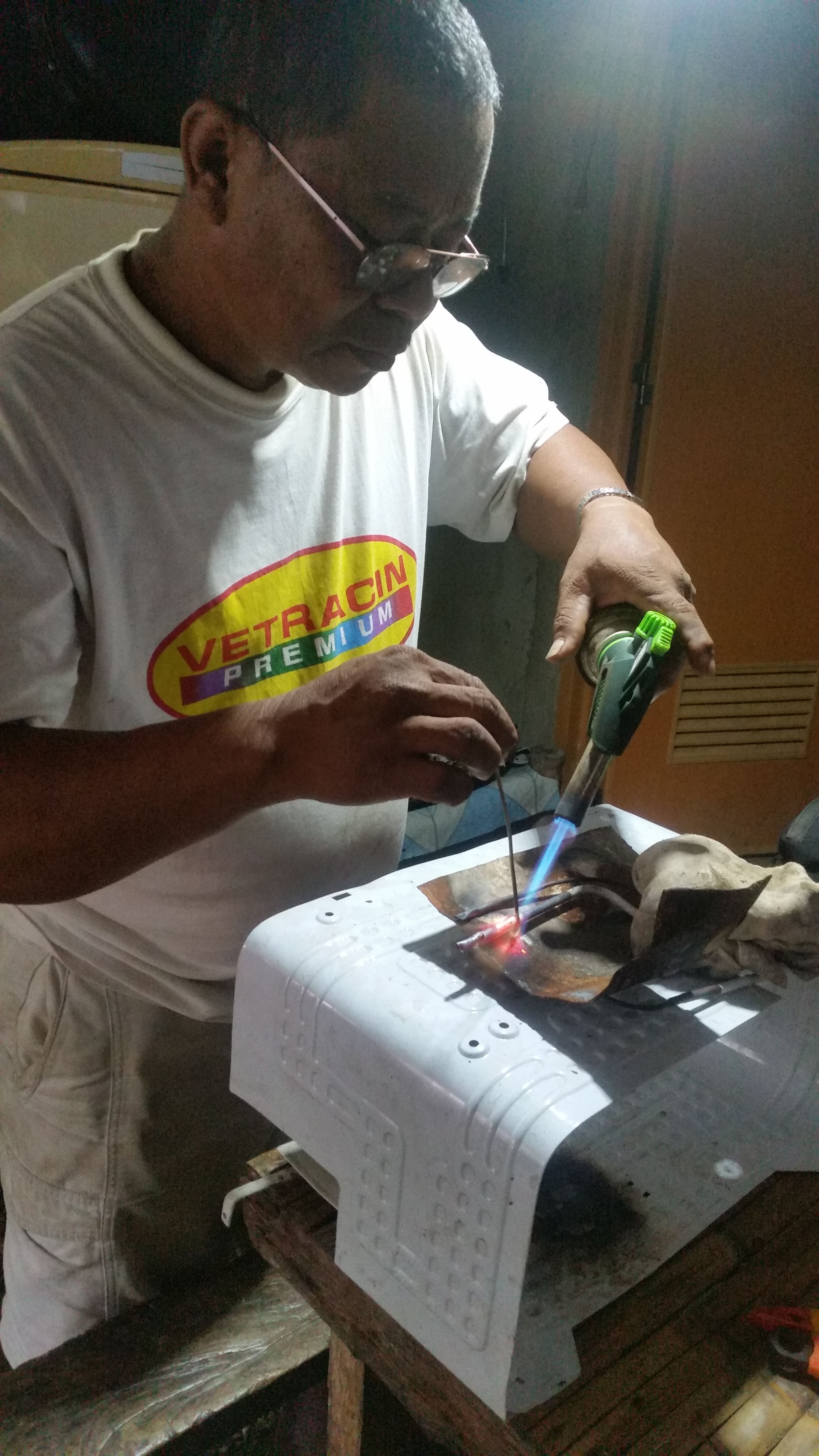

Aluminum evaporator is a part of the refrigerator where we put the frozen foods inside. When it is broken there is a tendency that it has a hole a particular very little ones that needs time to locate for it by flashing freon nitrogen to make a hard pressure and put a little soap bar on it so that i can determine when there is a hole that cannot be seen directly to the eye when the soap bubbles it means there is a tiny hole making the problem why it won't function at all, then finally soak it in the large basin of water to make sure there are no more other holes. Let it dry and start soldering its hole by the use of soldering aluminum rod stick and a mop gas.

Do it slowly and carefully because it is prone to melt easily the whole thing that may result to damage everything and can't be done at all but leave it as forever broken.

*i want to note that in this picture i am soldering an evaporator tube only but it has the same story like the process of fixing the evaporator itself. Until it will totally well done repaired.

Thanks for dropping by here and take time to read. @majimboangkabo

Upvoted

Please Consider Supporting Fellow redfish User by Upvoting Them

see redfish post here: https://steemit.com/created/redfish

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit