A Complete Guide to Feeler Gauges: Uses, Types, and Benefits

Introduction

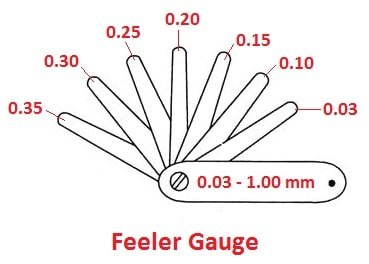

A feeler gauge is a precision measurement tool used to measure gap widths or clearances between two surfaces. Commonly used in mechanical, automotive, and machining industries, feeler gauges ensure parts fit accurately and operate smoothly.

- What is a Feeler Gauge?

A feeler gauge consists of thin metal strips or blades of varying thicknesses. These blades are precisely measured in millimeters or inches, allowing for accurate gap measurements. Feeler gauges are particularly important in tasks like valve adjustments, spark plug settings, and measuring bearing clearances in engines.

- Types of Feeler Gauges

There are several types of feeler gauges designed for different purposes:

• Straight Feeler Gauge: The most common type, with flat, straight blades. Ideal for measuring gaps in tight spaces.

• Angled Feeler Gauge: These gauges have blades bent at an angle, making them useful in hard-to-reach areas, such as engine valve settings.

• Go-No-Go Feeler Gauge: This tool combines two thicknesses—one that “goes” into the gap and one that “doesn’t”—for rapid testing.

- How to Use a Feeler Gauge

Using a feeler gauge is simple:

1. Select the appropriate blade thickness.

2. Insert the blade into the gap or clearance being measured.

3. Adjust the gap as necessary until the blade fits snugly but can still move without force.

4. Record the measurement for future reference.

Applications of Feeler Gauges

• Automotive Maintenance: Feeler gauges are commonly used for adjusting engine valve clearances, ensuring smooth operation of the camshaft and valve.

• Machining and Fabrication: These gauges measure precise gaps between parts in machinery or during assembly.

• Quality Control: In manufacturing, feeler gauges are used to check tolerances and ensure products meet specifications.Maintenance and Care

Proper care of feeler gauges ensures accuracy and longevity:

• Clean Regularly: Wipe blades clean after each use to prevent rust or corrosion.

• Store Properly: Keep gauges in a dry, protective case to avoid bending or damaging the blades.

• Check Calibration: Periodically verify the gauge’s accuracy using a micrometer.

Conclusion

Feeler gauges are vital for ensuring precise measurements in mechanical systems. Whether adjusting engine valves, measuring part tolerances, or performing quality control checks, these tools guarantee accurate and efficient work. By selecting the right type of gauge and maintaining it properly, you can rely on feeler gauges for long-term use.

Do you use feeler gauges in your work? Share your experiences and tips in the comments below! 💬

#FeelerGauge #PrecisionTools #MechanicalEngineering #DIY #Automotive