In recent times, the application of fish feed pellet extruder extrusion modern technology to feed manufacturing is an epoch-making leap in feed manufacturing technology. The major benefits of extruded granulation:

( 1 )The processing temperature is high and also the wetness content is big, and the product can be fully developed as well as weakened. The pellets are of good quality as well as the feed titer is high;

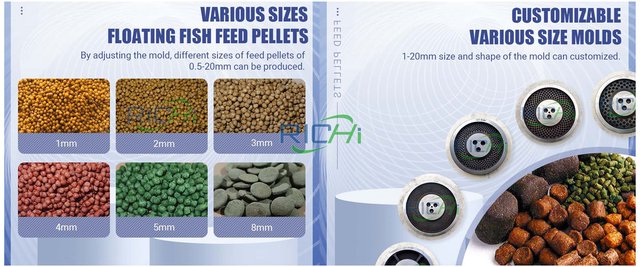

( 2 )The adjustable range of pellet density is large, which can adapt to the needs of various feeding things and also different feeding settings.

Related post: floating fish feed mill

( 1) Puffed suckling pig feed

The important indications of nursing pig feed are hygiene and also maturation to avoid suckling pigs from looseness of the bowels. The raw products are treated with heat and also high pressure, on the one hand, it eliminates pathogenic bacteria, on the other hand, the starch product is fully cooked, and the soybean healthy protein is denatured and also cleansed, so that the material is simple to digest and absorb. Gelatinized starch can promote the manufacturing of lactic acid in animals and boost the antibacterial capability of animals.

( 2) Extruded water feed

The marine feedl is extruded and granulated by fish feed pellet extruder, which enhances the top quality of the product from all aspects.

① Improved feed titer. Extrusion ripens the starch, which is important for fish as raw starch is tough to digest. The starch is prepared, the cohesiveness of the product is boosted, as well as the developing result is great. On the facility of guaranteeing the quality of pellets, the formula can be adapted to lower prices.

Related post: https://www.richipelletmachine.com/floating-fish-feed-mill/

② The floating time of pellets in water is managed by the thickness of pellets, as well as the density is established by the level of puffing by fish feed pellet extruder.

Therefore, by adjusting the formula, changing the variety and web content of starch as well as binder, and also readjusting the procedure criteria, that is, readjusting the dampness, pressure, temperature, etc, squeezed out pellets with different densities can be produced.

( 3) Puffed chicken feed

The formula of chicken feed includes high starch material and 15% -20% healthy protein material at the same time. For this proportion, despite the dry floating pellet maker or the wet drifting pellet maker, the technological efficiency is better.

Experiments have actually revealed that blowing can boost the digestion and absorption price of feed for hens. Extruded chicken feed, due to its small bulk density, can reduce chicken feed consumption, stay clear of excessive weight, and also enhance egg manufacturing.

( 4) Puffed cattle feed (urea blown corn).

Ruminants such as cattle and sheep can transform non-protein nitrogen (such as urea) right into pet healthy protein. The key to adding urea to feed is exactly how to regulate the enhancement amount, consistent feed intake as well as urea decomposition rate. Urea-expanded corn fixes these troubles most properly.

The urea, corn flour as well as additives are mixed in a particular proportion and then go into the floating pellet maker, the corn flour is broadened, and the gelatinized starch and also urea form a layer structure. Urease preventions hinder the activity of urease. It inhibits the launch rate of ammonia after urea decomposition from 2 facets, and also prevents ammonia poisoning triggered by excess ammonia.

Related post: 6-7T/H Fish Feed Plant

( 5) Rice bran conservation therapy.

Fresh rice bran includes really active lipolytic enzymes, which can promptly decompose the oil had in rice bran into free lipids.

Fat and rancidity, so the storage space efficiency of fresh rice bran is very poor. The rancid and ruined rice bran not just decreases the oil yield, however likewise influences the development and also growth of animals and also chicken if fed as feed.

As a result, fresh rice bran need to be maintained fresh in time. Extrusion, high temperature, high pressure as well as high shear can inactivate lipase and also avoid rancidity and wear and tear. Extrusion has actually ended up being a brand-new pretreatment process in rice bran oil manufacturing.

( 6) Detoxification of oilseed meal healthy protein.

In addition to soybean cake ( dish), the cake (meal) gotten from rapeseed, cottonseed, sunflower seed, castor and other oilseeds additionally consists of a certain amount of healthy protein, which is an exceptional source of feed protein. Nevertheless, different oil cakes (including soybean dish) can not be directly utilized to formulate feed, because they all include a particular quantity of anti-nutritional aspects or other harmful parts.

Oil cake (meal) should be purified before it can be used. Detoxification methods include chemical and physical techniques. Oilseed cake (meal) extrusion detoxing is a contemporary innovation applied to oil cake ( dish) treatment by extrusion technology.

( 7) Plume puffing handling.

Due to the existence of disulfide bonds and also hydrogen bonds in between plume polypeptide chains, the framework of feather healthy protein is specifically secure, and also animal digestion enzymes are generally not able to absorb and decompose, so the plume extrusion innovation has been developed.

After the feather is extruded as well as puffed, its disulfide bond is broken, the molecular framework is ruined, and the digestive enzyme is simple to absorb and also decompose, and also the digestibility is boosted. The digestibility is related to the level of degradation as well as extrusion temperature.

When the floating pellet maker extrusion temperature is high, the digestibility of the puffed feather product boosts, yet the amino acid material of the item reduces similarly, and the healthy protein top quality of the item reduces.

Feather dish has high healthy protein material, but the amino acid is not balanced enough. In order to solve this problem, chicken viscera, poultry blood and also feathers can be blended as well as refined into digestive plume meal.

Fish feed pellet extruder extruding modern technology is a feed processing modern technology established at the end of the 20th century. Stress cutting has a excellent impact on regulating the thickness of extruded products, giving a brand-new approach for processing high-demand aquafeeds.

Making use of waste heavy steam as well as waste heat for conditioning makes the equipment much more eco-friendly and also adapts to the trend of the moments. Extrusion technology of fish feed pellet extruder is widely made use of in marine, swine as well as ruminant feeds, which has a considerable impact on changing feed quality and minimizing costs.

With the growth of fish feed pellet extruder squeezing out modern technology, even more extensive research study is required on exactly how to properly regulate the expansiveness and also extruding high quality of extruded feed, and also boost the automation of extruding.

For details please contact: Richi Machinery

WhatsApp:86 138 3838 9622

Email:[email protected]