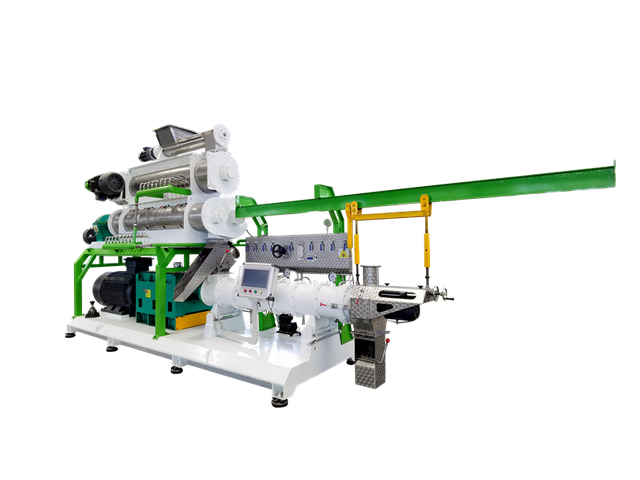

The main function of the fish feed floating pellet making device is to straight squeeze out puffed food. Generally, grains, potatoes or beans are utilized as the primary basic materials.

After being squeezed out by thefloating fish feed making maker, under the conditions of heat as well as high pressure, the item is blown by using the pressure difference inside and also outside the maker

The straight extrusion kind puffed food usually does not contain lead, as well as now the fish feed drifting pellet making device is widely utilized in the food industry. So how much do you understand about the drifting fish feed extruder? The fish feed drifting pellet making machine has a set of screws and a screw sleeve, which have the functions of blending and kneading.

After the raw product goes into the extruding dental caries, the product is subjected to extrusion, friction as well as shearing between the screw sleeves, and also the inner stress remains to increase, up to 4Mpa, and the temperature level continues to increase, up to 140 ℃.

Related post: Fish feed extruder machine

Within 3-7s, the temperature level and stress of fish feed drifting pellet making maker rise greatly, and the tissue structure of the product adjustments, which better gelatinizes the starch, denatures the healthy protein, damages the unrefined fiber, and eliminates damaging microorganisms such as Salmonella.

The high-temperature as well as high-pressure product appears of the discharge port, and its pressure is suddenly launched in an split second, and the moisture is partially blinked.

1. The structure of drifting pellet making equipment.

The feeder is to guarantee uniform as well as steady feeding, as well as adjust the feeding quantity according to the rated existing worth of the electric motor of fish feed floating pellet making equipment. Normally, an electromagnetic speed-regulating motor or a regularity converter is used to readjust the rate, and the feeding quantity of the feeder is altered.

Development dental caries of fish feed drifting pellet making device is made up of screw, screw sleeve, layout, card bone and so forth. The screw and also screw sleeve are integrated in sections, the compression degree can be changed according to the type and also requirements of the extruded feed, and also the extruded level of the extruded feed can be changed;

Related post:https://www.richipelletmachine.com/fish-feed-extruder-machine/

The fish feed drifting pellet making machine is split into three areas in terms of collapse degree according to work and position:

① Feeding area: This section of floating fish feed maker has a large screw pitch, and mostly conveys and also compresses the product so that the product loads the spiral groove;

② Compression area: The screw groove of this section adjustments from deep to superficial along the material moving direction to compress the product;

③ Extrusion section: the screw groove is shallower, the pitch gradually diminishes, the extrusion pressure can get to 3.0-10Mpa, and the temperature level can reach 120-150 degrees Celsius. This section has the highest pressure and also greatest temperature, so the wear of the screw and also screw sleeve is also one of the most significant. hop over to this web-site

The outlet of the extrusion section is a design template, the shape of the layout is developed with different die holes according to the demands of various feeds, the material is squeezed out from the die opening of the theme and gets in the environment, the pressure and temperature level decline greatly, as well as its volume broadens swiftly, the water swiftly evaporates, dehydrates as well as strengthens to become an extruded material.

2. Fixing of fish feed drifting pellet making machine

Transform the fish feed floating pellet making equipment on-site control switch to the stop state during maintenance;

The within as well as beyond the fish feed drifting pellet making device should be cleaned after each shift, especially the material needs to not be kept in the puffing chamber, so regarding avoid it being tough to clean up after cooling and also load;

Related post: 1-60T/H Floating Fish Feed Mill

The huge sheave of the primary shaft of the puffing chamber ought to be cleaned up frequently, and not too much dust, otherwise the sheave will certainly be out of balance as well as the puffing chamber will certainly shake;

The primary bearing of the expansion chamber is oiled with lubricating oil, and the bearing of the fish feed floating pellet making device conditioner and its transmission tool as well as various other bearing parts are lubricated with grease;

The main bearing needs to be replaced with new oil regularly. After 250 hrs of job, all brand-new oil needs to be replaced;

Various other bearing components, every two days of job, grease is injected when;

The chain transmission device on the vapor conditioner need to be lubed regularly;

The oil in the reducer of fish feed floating pellet making equipment must be managed at the calibrated oil level, and also the brand-new oil should be changed after 250 hrs of operation;

When getting rid of the screw head, do not knock it hard;

Constantly keep the fish feed drifting pellet making device and also its environments clean.

For details please contact: pellet plant

WhatsApp:86 138 3838 9622

Email:[email protected]