IMARC Group’s report titled “Flow Chemistry Market Report by Reactor (Continuous Stirred Tank Reactor, Plug Flow Reactor, Microreactor, Microwave System, and Others), Application (Pharmaceuticals, Chemicals, Academia and Research, Petrochemicals, and Others), and Region 2025-2033”. The global flow chemistry market size reached USD 2.0 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 4.5 Billion by 2033, exhibiting a growth rate (CAGR) of 8.38% during 2025-2033.

Factors Affecting the Growth of the Flow Chemistry Industry:

- Increasing Focus on Productivity:

This factor informs that the growth of the market has been propelled by the quest for efficiency and Production. Flow chemistry allows the process of continuous introduction of reactants and the removal of products. This means that synthesis is continuous and uninter- rupted in a continuous process rather than stop-and-go as in batch processing. The continuous method, again, accelerates reactions and makes it easier to attain uniform synthesis at an industrial size. Further, it avoids long time consumed in the cleaning and preparation of the next batch of reactors, thus, exhibiting increased production.

- Growing Need for Enhanced Safety:

From the study, flow chemistry enhance the safety of chemicals manufacturing. It requires the use of small amounts of the reacting materials in a limited region. This ensure that there are no explosions or hazardous reactions which is different from batch reactors. Lower amounts ensure detrimental reactions’ impacts are minimized, as well as hazardous materials’ usage is controlled. Moreover, non-flow closed systems reduce the problem of toxic gases and leaks in the process of flow reactors. This serves the interest of the environment and people. Therefore, the aspects of safety are significant for flow chemistry useful in industries dealing with reactive or toxic compounds.

- Improved Reaction Control:

So flow chemistry systems are argued to offer better control over temperature, pressure and time. This enhances selectivity and settle in incumbent chemical reactors. Flow reactors combine quickly and transfer heat from a reactant to the other reactant. This enables the use of observational data to be complemented by data. Such control is beneficial in fine tuning cancer, determining better ways of communicating or new ways of treating it. It also helps make consistent constants to support replicability and growability in the software. This is significant in the areas of medicine for instance because quality and stability are desirable attributes in products.

Grab a sample PDF of this report: https://www.imarcgroup.com/flow-chemistry-market/requestsample

Leading Companies Operating in the Global Flow Chemistry Industry:

- AM Technology

- Chemtrix BV

- Corning Incorporated

- Ehrfeld Mikrotechnik GmbH

- FutureChemistry Holding B.V.

- HEL Ltd.

- Lonza Group AG

- Milestone Srl

- Parr Instruments Company

- Syrris Ltd (Asahi Glassplant Inc.)

- ThalesNano Inc

Flow Chemistry Market Report Segmentation:

By Reactor:

- Continuous Stirred Tank Reactor

- Plug Flow Reactor

- Microreactor

- Microwave System

- Others

Continuous stirred tank reactor represents the largest segment as it maintains a steady-state operation while allowing for efficient mixing and reaction control.

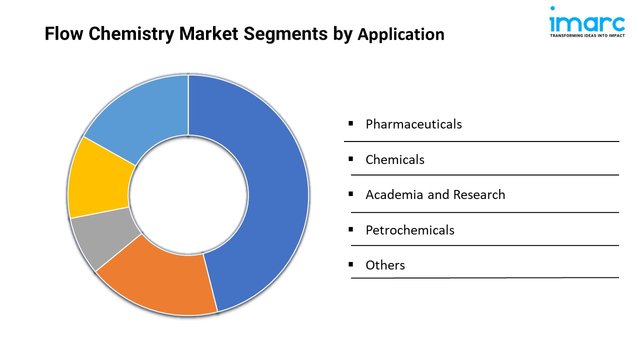

By Application:

- Pharmaceuticals

- Chemicals

- Academia and Research

- Petrochemicals

- Others

Chemicals hold the biggest market share due to the rising focus on optimizing reaction conditions and minimizing waste.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America enjoys a leading position in the flow chemistry market, which can be attributed to the burgeoning pharmaceutical sector.

Global Flow Chemistry Market Trends:

Flow chemistry, though not new, can make chlorinated processes greener. It reduces solvent and energy use and optimizes resources. This aligns with the growing demand for green chemistry and sustainable methods. Moreover, flow chemistry requires less energy and raw materials, needs fewer workers, and doesn't need large plants.

There's been a steady improvement in flow chemistry technology. Advances have been made in reactors and monitoring technologies, boosting market growth.

Note: If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145