Did you notice how most things in the world stand in binary opposition?

You are either cold or hot, smart or dumb, single or in a relationship…

The food is either good or bad. It’s either day or night outside …

We people love to perceive the world around us in well-known categories, which are in more cases than not is some kind of opposition, and usually, one of them is perceived as better.

Knives are no exception, actually, categories of knife domain are a bit more complex than you may have imagined.

You have your forged and ground knives, full tang and hidden tang, dull knives and sharp ones, folder knives and full blades, bushcraft and kitchen knives, specialized and all-around knives...

There are simply too many aspects of knife usage and making to cover them all in one post...

So, let’s start from the beginning and see how far we’ll go today.

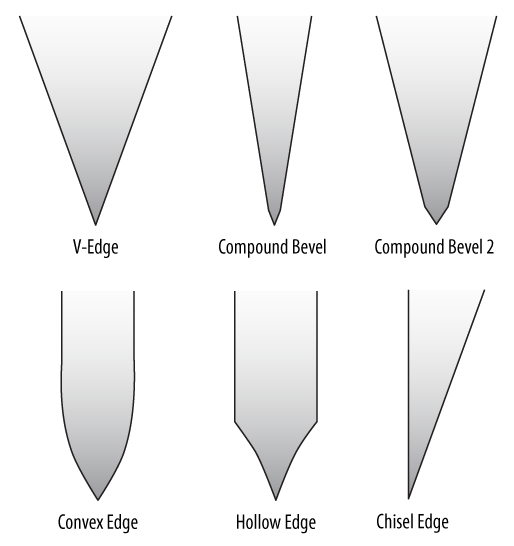

A knife is basically a piece of (usually) steel which was manipulated in some way to get the two planes together as close as humanly possible - a knife bevel. When this is done properly a knife is sharp. This can be done in quite a few ways and a good knifemaker chooses the type of bevel based on the function the knife will have.

Steel

Steel is an alloy which consists of around 90% or iron and 0.5 – 2.5% of carbon. The iron and the carbon are elements that make steel. Other elements can be found either as impurities or as add-ons in order to manipulate the various properties of steel.

high carbon steel: a high carbon steel is a synonym for a simple steel that has around 1% of carbon and not much of anything else

stainless steel is a steel that is (to a certain degree resistant to rust). A steel is considered to be stainless when it has more than 10%(13%) of chromium.

So which one is better? Well, nobody likes rust so it must be stainless – right? What if I told you that most of the high-end handmade and custom knives are made of (simple) high carbon steels? Not only that but when talking about knives for food preparation (enter the professional chefs) high carbon knives are considered a must.

But Doc, don’t they rust?

Well, they will and then not really. The thing you need to know about knives is that you do have to take care of them, and I don’t mean dropping them into a sink or a dishwasher, but taking care of them as you would a supercar.

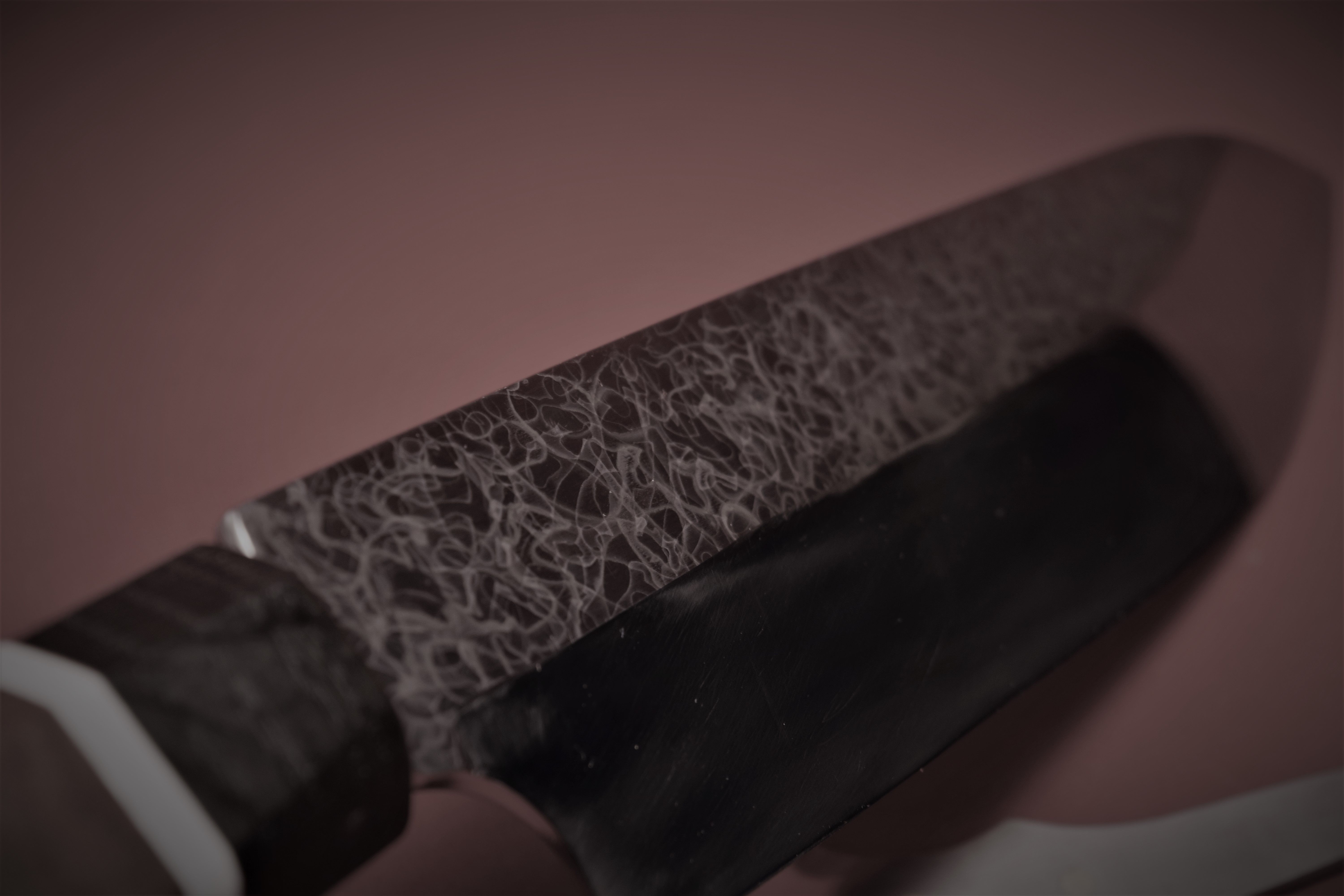

And there's a patina which, if a knife is properly maintained, will develop over the time and your non-stainless knife will start to look like a proper tool.

Or a knifemaker will force one and then a knife can become a piece of art.

Here is a Walter’s video where he’s explaining most of this stuff and giving a few guidelines about how to take care of your knife. Also, check him out on his YouTube channel he has some awesome videos about making knives.

Making a knife

There are two ways one can make a knife: by forging a lump of steel and by removing the steel from a flat stock – AKA stock removal.

forging a steel is basically heating the steel at high temperature and then hitting it with some kind of a hard object – usually a hammer until you move the steel to the desired shape.

stock removal is when you take a flat bar, you sketch a shape you want to have and remove all the rest.

Which one is better?

If you ask a purist forge guy you will most probably hear something along this lines: “only a forged knife can be considered a custom knife – all them stock removal guys are just kids with no skill who are playing around with steel…”.

If you ask a stock removal guy something like this will be heard: “the only reason to forge steel is if you are making laminated steel (AKA Damascus – I’ll cover that in some future session) – why would you spend all that energy to get the steel to a proper shape when in the end you’ll still have to grind…”

.jpg)

As far as I’m concerned, both ways of making a knife are valid – one should use the technique and tools one feels most comfortable with. Actually, to be honest I do tend to lean a bit more toward stock removal. I do like forging, but you can’t really forge a knife without grinding at the end. And, if you are using modern steels that come in bars or sheets, forging really is a waste of time and energy.

On the other hand, forged knives, when done right can have some amazing looking finishes.

That’s it for today, in the next session I’ll do my best to present arguments for buying a hand-made knife and what should you expect for your money.

If you like this topic feel free to comment, ask me a question or suggest a topic you would be interested in reading.

Amazing talent! I'm really impressed by your work my friend!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thank you. This is just the start I will be slowly bringing up the game as we move along. So, stay tuned and look out for some awesome creations.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

@originalworks

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

The @OriginalWorks bot has determined this post by @docsmith to be original material and upvoted it!

To call @OriginalWorks, simply reply to any post with @originalworks or !originalworks in your message!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

This post has received a 1.06 % upvote from @boomerang thanks to: @docsmith

@boomerang distributes 100% of the SBD and up to 80% of the Curation Rewards to STEEM POWER Delegators. If you want to bid for votes or want to delegate SP please read the @boomerang whitepaper.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

This post has received a 0.80 % upvote from @buildawhale thanks to: @docsmith. Send at least 1 SBD to @buildawhale with a post link in the memo field for a portion of the next vote.

To support our daily curation initiative, please vote on my owner, @themarkymark, as a Steem Witness

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

GREAT POST! I'm a stock removal guy myself. I've used both stainless and high carbon steels. Most of my current models have been done out of stainless though. I do plan on trying to forge my own damascus at some time down the road in my knife making journey but that wont be any time soon...haha. Overall knife making has been hard work but very rewarding!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit