In the recent past the Oil and Gas (O&G) industry has achieved huge gains in efficiency and cost reduction. O&G has the advantage of a large number of wells drilled, investment and people. The geothermal industry has a much smaller number of wells so such a revolution would be harder to achieve. As such, my aim with this article is to explore the size of the potential opportunity, the risks involved in geothermal power exploration projects, geothermal drilling challenges and lastly technology crossover from the O&G industry that would help reduce drilling risk.

Geothermal energy is heat within the earth. People drill deep wells into the ground to access this heat in the form of steam. This steam once produced may be used to turn a turbine and generate electricity. Additionally, there are various direct utilization applications including district heating, greenhouses and food drying and geothermal heat pumps which are used to heat and cool buildings. However, this article will only focus on geothermal well drilling for power production.

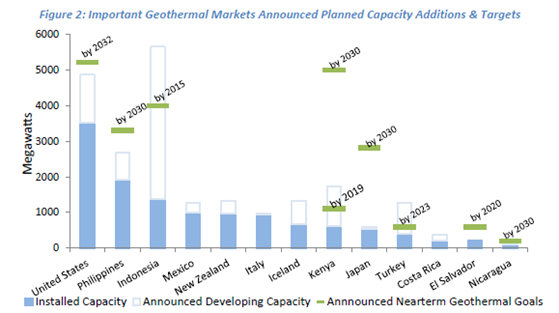

The graph below shows the planned geothermal power projects to 2030 in Megawatts and gives an indication of the size of the opportunity.

In summary the Planned projects in the eastern hemisphere (EHO) are approximately 20 GW while in the western hemisphere (WHO) they are 2.6GW. Using an estimated production of 7MW per well this translates to an estimated 3700 wells in the EHO and 500 wells in the WHO. This is a small fraction of the number of oil and gas wells drilled annually. In addition, only 6.5% of global geothermal potential of 195 GW (based on current technology and knowledge) has been exploited to date, which shows that there is plenty of room for growth.

Early stage geothermal projects tend to have high risk, due to the high upfront costs associated with exploration drilling focused on finding the geothermal resource in a previously unexplored area. Most strategies for reducing investor and developer risk focus on providing grant funding or insurance for exploration drilling. One additional way to reduce the risk and costs involved in exploration drilling is to use customized tried and tested techniques and equipment from the O&G industry to optimize the drilling process and reduce the drilling time and cost.

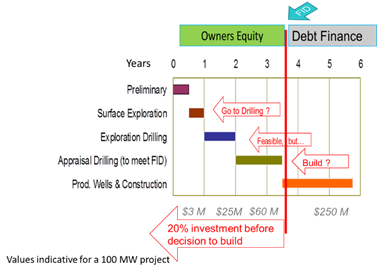

The typical geothermal project lifecycle is shown in the chart below. The costs shown are indicative of a typical 100MW project.

From the chart it can be seen that there are significant upfront costs and risk associated with geothermal exploration and appraisal drilling. Most of the work up unto the end of appraisal drilling will be owner funded with perhaps some funded through support funds such as GRMF( Geothermal Risk Mitigation Fund). Up to 20% of the cost of the entire project is made before the decision to build a power plant is made. This is a substantial investment, the bulk of which can be attributed to exploration and appraisal drilling at $5-8m per well. After appraisal drilling a significant part of the risk associated with the project will have been mitigated with funding usually available from financing institutions to finance the rest of the project.

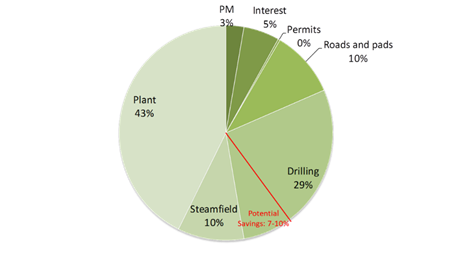

The pie chart below shows the split in geothermal project costs.

Total drilling cost accounts for 29% of overall project cost on average. For a 100MW project costing a total $340M the drilling cost is approximately $100M. Through various optimization technologies a total saving of $7-10M is possible for such a project. By using the right technologies it is possible to increase drilling efficiency, not only faster drilling but also the benefit of better production

Geothermal Drilling Risks and Crossover Oil and Gas technology solutions

We will now summarize the key risks related to geothermal drilling and the technologies which have crossed over or have the potential to cross over from O&G. These technologies seek to provide solutions for the key technical needs of geothermal projects: faster drilling leading to reduce drilling costs; improved formation characterization to determine reservoir characteristics; application of reservoir stimulation to optimize the well output.

a) Risk: Very hard and abrasive formations: Basalt, trachyte etc leading to low penetration rate and long drilling periods of up to 60-90 days. Damage caused by these formations may also lead to premature drill bits and drilling tool failures.

Solutions:

Engineered roller cone(which have three rotating cones) drill bits that are designed to better handle harder rocks and high temperatures. Positive displacement drilling motors which use hydraulic horsepower of the drilling fluid to drive the drill bit, that are built to survive temperatures over 300 deg. C.

Drilling optimization with data analytics; A recent drilling data analytics optimization project in which I participated involved the following phases:

Data collection during drilling using surface and down hole data recorders.

Analysis to gather information from the data and to develop optimization solutions.

Iterative drilling performance improvement over the course of the drilling project attained by changing drilling parameters, drill bits and BHA (bottom hole assembly) designs.

Results: increased rate of penetration and reduction in number of trips into and out of the hole.

b) Risk: Unstable, unconsolidated formations which sometimes cave in leading to problems of stuck pipe.

Solutions

Drilling with casing: In this case the casing is used as the drill string to rotate the drill bit so that it is already in place when the well reaches the desired depth. Advantages are, the method can be used to gain casing setting depth by drilling through lost circulation zones or weak formations. The method also eliminates the time and of cost of pulling out of hole with the drill pipe then running the casing to the bottom of the hole on a separate trip.

(courtesy Odjfell).

c) Risk: Fractured formations require aerated drilling fluids due to challenges with lost circulation. Aerated fluids create a communication challenge for most oilfield tools which usually send signals to surface using mud pulse telemetry.

Solutions:

Real time data collection, transmission and interpretation would eliminate lost time correcting well direction. Because wells are drilled using aerated drilling fluids this rules out the use of conventional MWD(measurement while drilling) which uses mud pulse telemetry. One possible solution is to use Electromagnetic- Measurement While Drilling (EM- MWD) which allows measurement of bit position and formation characteristics and transmission of this data to surface using electromagnetic waves. This data can be used to navigate and allow production optimization.

d) Risk: High Temperatures from 160 deg.C to 300 deg. C. Most oilfield tools function at maximum temperatures of about 150 deg.C.

Solutions:

Formation characterization tools are needed to locate the best possible location in the well for stimulation and analyse fractures in the well eg. acoustic sensors, resistivity probes, natural gamma ray detectors.

Stimulation tools are needed to fracture rock and improve well productivity. Packers are required to localize hydraulic pressure during fracturing and seismic sensors in the well to improve fracture mapping.

Maintenance tools for future high flow geothermal wells with require smart well technology. These will give an indication of the ‘health’ of the well and include down hole sensors and casing inspection tools.

Summary

In summary the geothermal industry stands to gain a lot from the efficiency and progress already achieved in the O&G industry to reduce risks in exploration drilling. Significant challenges still remain around making tools for High Temperature 300 deg.C applications which can improve drilling efficiency, reservoir characterization, well productivity and maintenance. In addition, funding is not as abundant nor research into solving challenges as common as the O&G industry. The list of technologies proposed to address the main drilling risks is not exhaustive but gives an indication of the main areas of focus. The growth potential of geothermal energy is still huge, global production is only about 6.5% of the current hydrothermal resources potential of 195 GW. In addition we have only started scratch the surface of the immense potential of deep/dry rock geothermal resources which lack sufficient fluids and permeability but which is much more prevalent.

Geothermal energy is stable and available around the clock making it ideal for base power production. It is renewable and sustainable and is set form an important part of the energy mix of the future as the world seeks to meet goal for affordable, reliable, sustainable and modern energy for all (Sustainable Development Goal-7).

By: Eng. Mathew Mwenga, Ren Company Limited

http://www.ren-engineering-solutions.com/

Also on behalf of: ECP24

References

Annual U.S & Global Geothermal Power Production Report- Feb 2015

IEA-Technology Roadmap-2011

World Energy Resources: Geothermal, World Energy Council, 2013.

IFC drilling success, 2013.

Jacobs introduction to Geothermal Energy

Handbook of Geothermal best practices.

High temperature working paper- Aug 2012.

Future of Geothermal Energy-Nov 2006

Congratulations @wamwenga! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Do not miss the last post from @steemitboard:

Vote for @Steemitboard as a witness to get one more award and increased upvotes!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Congratulations @wamwenga! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Do not miss the last post from @steemitboard:

Vote for @Steemitboard as a witness to get one more award and increased upvotes!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit