Sharing a basic gunsmithing process.

A lot of people locally have been asking me for polished AR-15 triggers lately. The process make the trigger pull smother and not feel gritty. If done properly it can also reduce the trigger pull slightly.

Here is what I have. 1 trigger, 1 hammer, and one disconnect. I use 1500grit wet sand paper some polishing compound and I use a rotary tool.

The surface needing polishing are the face of the trigger. First thing I do is make 3 passes across the sand paper with the trigger. Ensure to maintain the angle or you can make the trigger unsafe or unusable. The three passes takes off the machining marks. Best way I have found to do this is place the sandpaper on my bench and pull the trigger across the paper. It gives the paper a sold serface and help maintain the angle. Then load up your polishing wheel which compound and carefully buff your trigger face to a mirror finish. Like this

Sorry my iPhone camera is kinda bad.

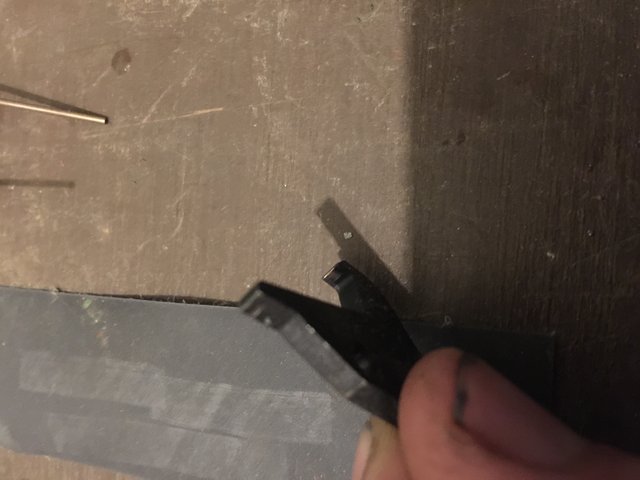

Next I polish the disconnect the small area needing polished here is this little hook.

Polish it to a mirror finish. This is vary important not to over work this area. If done improperly the hammer won’t catch and your AR won’t stop firing.

Next the hammer need attention. The hook that connects to the disconnect is what needs polishing here. Same consideration here don’t over do it.

I also polish where the hammer connect the trigger the little notch on the bottom of the hammer. Some say it is over kill but I polish the top of the trigger face also.

My triggers polished with Kaw valley spring kits average 4.2lb trigger pull.

I sell the kit pictured with hammer, trigger, disconnect, spring kit, and anti walk pins polished for $79 beats the hell out of a drop in for $150-400