Researchers at the Zurich Institute of Technology have discovered plastics that can be easily disintegrated into their basic pieces, according to their findings.

Plastics are a low-cost, long-lasting material that can be recycled. They are capable of taking on any form and performing practically any duty. Plastics, on the other hand, are a major source of concern for both the environment and living organisms. Plastics are extremely difficult to decompose in the natural environment. The environmental damage caused by waste plastics that cannot be recycled continues for an extended period of time, endangering the health of all living things in the ecosystem.

Source

One technique for reducing plastic pollution is to recycle as much plastic as feasible as much as possible. Plastic recycling, on the other hand, is fraught with complications. The first thing to note is that while all plastics are polymers (a long, chain-shaped molecule composed of repeating units), different raw materials are used to manufacture different types of plastics.

This means that, before some types of plastics (such as PET and PVC) can be recycled, they must first be separated from other types of plastics in order to be recycled properly. A combination of human contact and sophisticated technology is typically required for the decomposition of plastics. Second, recycling processes that are widely used cannot be considered to be particularly beneficial in terms of energy conservation.

SourcePlastic recycling

Plastics are recycled on a regular basis today, primarily through mechanical means. Prior to being melted and re-poured into the mold, the garbage is broken up into little pieces. However, during the course of each recycling operation, these mechanical activities lead the polymer chains to shorten, resulting in a reduction in the quality of the material that is created. It follows as a result that mechanical recycling of plastics will be impossible in perpetuity.

Decomposing plastics first and then repolymerizing them would be a significantly more successful method of recycling than what is now in use. A variety of breakdown and repolymerization techniques have been developed for a wide variety of polymers. These alternatives, on the other hand, consume a lot of energy and are not particularly cost-effective.

SourceBiodegradable plastic

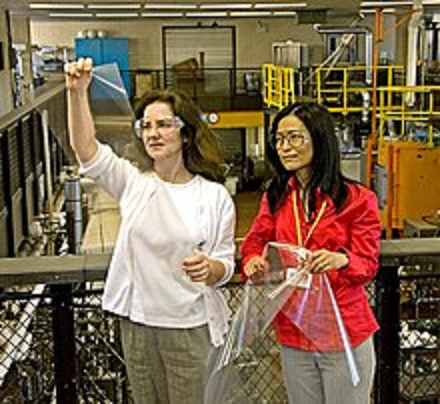

According to a study published in the Journal of the American Chemical Society, Athina Anastasaki and her students were able to recover 92 percent of the original raw material by re-decomposing the polymers they had created. Plastic glass, often known as mica, is a type of polymer that has been produced by researchers for use in many applications.

It is necessary to produce polymer chains of equal length during the synthesis process, and this is accomplished through the use of a recently invented technique called as RAFT for short. A chemical group is added to the end of polymer chains to ensure that the polymers formed are easily disintegrated into their constituent parts once they are formed. As soon as the temperature of the substance is raised to 120 degrees Celsius, the chemical group begins the decomposition process.

In the medium run, it seems unlikely that the newly developed method will provide a solution to the problem of plastic pollution. First and foremost, research must be carried out to ensure that the new technology is suitable for use in industrial polymer manufacturing applications. A further disadvantage of the new approach is that it does not allow for the breakdown of today's polymers into their basic parts.

References: