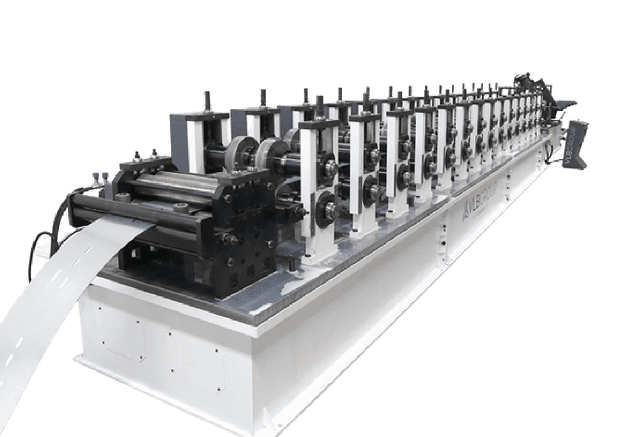

A staple of contemporary manufacturing, roll forming has become the go-to method for producing metal components with extreme accuracy and efficiency. This process is unique in that it can smoothly and consistently create continuous metal strips into intricate shapes and features. Tube Form Solutions’ roll forming lines are a prime example of this technology’s achievements. These lines combine advanced controls with knowledge of tooling to help companies optimize their manufacturing operations. Manufacturers may confidently and easily achieve rigorous production deadlines, improve product quality, and minimize material waste by utilizing roll forming lines. This creative method helps companies provide better outcomes for their clients while also increasing operational efficiency.

Understanding Roll Forming

Roll forming is the technique of gradually shaping a continuous strip of metal by running it through a number of rollers (or stands). Every roll stand carries out a distinct bending process that gradually shapes the metal into the required shape. For the creation of lengthy, consistent metal profiles used in the construction, automotive, aerospace, and other industries, this process is especially beneficial.

Benefits of Roll Forming Lines

Efficiency: The design of roll forming lines prioritizes efficiency. Their ability to provide uninterrupted output makes them perfect for high-volume manufacturing. These lines increase output while drastically lowering labor expenses by automating the shaping process.

Customizability: The adaptability of roll forming lines is one of their best qualities. With just a few roll tooling configuration changes, they can be made to generate an almost infinite variety of profiles and forms. This adaptability spares producers from having to retool extensively in order to react swiftly to shifting market needs.

Precision and Consistency: Roll shaping provides excellent consistency and dimensional correctness. Utilizing computer-controlled systems minimizes material waste and rework by guaranteeing that every component satisfies precise specifications.

Material Savings: Roll shaping maximizes the use of material. It reduces material stress and waste by gently shaping the metal, which saves money in comparison to more conventional forming techniques.

Tube Form Solutions: Leading the Way

At the forefront of roll forming technology, Tube Form Solutions provides creative solutions suited to the unique requirements of manufacturers. Their roll forming lines are designed with efficiency, dependability, and user-friendliness in mind, enabling enterprises to effectively meet their production targets.

Key Features of Tube Form Solutions Roll Forming Lines

Advanced Controls: To give operators exact control over the forming process, Tube Form Solutions incorporates cutting-edge control systems into their roll forming lines.

Tooling Expertise: Tube Form Solutions has decades of experience and provides complete tooling solutions to ensure the lifetime and best possible performance of their roll forming processes.

Customization: Tube Form Solutions offers roll forming lines that may be tailored to meet specific production needs. Businesses can increase production and product quality because of this flexibility.

Technical assistance: Tube Form Solutions offers outstanding technical assistance and training in addition to equipment sales, making sure that clients can make the most out of their roll forming operations.

Encouraging Excellence in Manufacturing

In today’s competitive production world, quality and efficiency are key considerations. Tube Form Solutions’ roll forming lines are prime examples of their dedication to quality, helping companies increase production capacity and bring better goods to market.

In summary

Metal forming has been transformed by roll forming lines, which provide a combination of accuracy, effectiveness, and adaptability that is difficult for conventional techniques to match. Investing in roll forming technology is a strategic choice for firms who want to stay competitive in today’s changing industry and optimize their operations. Tube Form Solutions is prepared to provide companies with innovative solutions that open doors to superior manufacturing.

Hello @inspirehub

Maybe you are part of the newcomers to our platform. I will tell you that as a new user of the #steemit platform must follow the rules of the community and must complete their task of achievement. It will help you to learn about this platform.

Newcomers' Community will help them in this aspect and etiquette on steemit platform here. You can also follow this link to complete tasks on the steemit platform.

After completing all these guidelines, aUser can post in any community according to their rules. As long as members are in good standing, if they are caught committing any kind of abuse, they will be silenced from the community and will also be subject to downvoting.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit