Source

Source

Polyester

The word “ester” is the name given to salts formed from the reaction between an alcohol and acid. “Polyester” means many organic salts. Polyester is a man made, synthetic polymer spun in the form of polyester filament or staple fibre. The most commonly polyester filament or staple fibre is usually composed of Polyethylene Terephthalate polymers.

Commercial or Trade name:

| Trade name | Country |

|---|---|

| Dacron | USA |

| Terylene | UK |

| Fortrel | USA |

| Tetoron | Japan |

| Trivera | Japan |

| Pentron | Japan |

| Lambda | USA |

Types of polyester:

Polyesters are subdivided into the following types, based upon their chemical structures and abbreviations shown that are used in referring to the fibres:

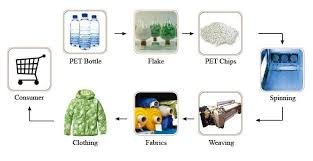

- Polyethylene Terephthalate fibre (PET polyester)

- Poly- 1,4- cyclo hexylene Dimethylene Terephthalate fibres (PCDT polyester fibres)

- Other types of polyester fibres.

1.PET polyester:

PET is made by the condensation of Terephthalic acid or a derivative such as dimethyl terephthalate with ethylene glycol.

2.PCDT:

PCDT polyester fibres are spun from poly -1,4- cyclo hexylene dimethylene terephthalate made by condensing Terephthalic acid with 1,4- cyclo hexane dimethanol,

Diameter: 12 µm to 25 µm.

Appearance: Smooth with round cross-section.

Moisture regain: 0-0.4% (Hydrophobic for extreme crystallinity).

Dye used: Disperse, azoic, some pigments are used for dyeing fibre.

Physical properties:

1.Tenacity:

Polyester filaments and staple fibres are strong to very strong because of their extremely crystalline polymer system. The tenacity of polyester filaments or staple fibres remains unchanged when wet because of the completely hydrophobic and extremely crystalline polymer system.High tenacity filament 7- 8 gm/ den.

Normal tenacity filament 4.5-5.0”

Staple fibre 3.5-4.0”

2.Elastic plastic nature:

Polyester filaments or staple fibres are as plastic as they can be seen from their distortion on repeated stretching and straining. This is entirely due to the Vander Waal’s forces which hold the polyester polymer system together.

- In case of 2% extension.

- Breaking extension 20-30% and

- Elastic recovery 97-100%

3.Hygroscopic nature: Polyester filaments and staple fibre are hydrophobic. The lack of polarity and the extremely crystalline structure of polyester polymers resist the entry of water molecules into the polymer system.

MR%: 0-0.4%.

1.Effect of acid:

Source

The ester groups of the polyester polymers are resistant to acid hydrolysis. This resistance is further increased by the extreme crystallinity of the polyester polymer system which prevents the entry of any acid and water molecules into the filament or staple fibre.

2.Effect of alkali:

Source

Alkaline conditions during laundering may hydrolyze the polyester polymers at their ester groups. The extreme crystallinity of the polyester polymer restricts the hydrolysis to the surface of the polyester filament or staple fibre.

3.Effect of bleaches:

Normally polyester textile materials do not need to be bleached. If bleaching is required this is done by using Sodium Chlorite.

4.Sunlight: The acid resistance of polyesters protects polyester textile materials from the slightly acidic conditions that occur in polluted atmospheres. The benzene rings of the polyester polymer provide stability to the whole polymer, enabling the polymers to withstand the detrimental effect of the sun’s ultra violet radiation.

5.Dye ability: It is very difficult for dye molecules to penetrate the extremely crystalline polymer system of polyester fibres. Only the relatively small molecules of disperse dyes are used to dye or print polyester fibres.

6.Biological agents: Resistant to moths, mildews, fungus.

7.Solvents: Resistant to all dry cleaning solvents.

8.Flammability: Burn slowly.

Source

Thermo plasticity:

‘Thermo plasticity’ means capable of being shaped or moulded when heated. Thermoplastic fibres heated under strictly controlled temperatures to soften and made them to form a flat, creased or pleated configuration. When cooled, thermoplastic fibres will retain the desired configuration.

Source

The polyester fabric has wrinkle free appearance and easy to care in use. It requires little or no ironing, are easy to launder and quick to dry.

I)Apparel use: Men’s, women’s, children’s wear, tropical suiting, blended with cotton, wool, acrylic, nylon etc. for dresses, goods and other purposes.

II) Domestic use: Upholstery, floor covering, carpet etc.

III) Industrial use: High tenacity PET for tire cords, v-belt, ropes, fire hoses, sail cloth, conveyor belts, paper making.

You have been upvoted by @tarpan A Country Representative from BANGLADESH we are voting with the Steemit Community Curator @steemcurator07 account to support the newcomers coming into steemit.

Follow @steemitblog for the latest update. You can also check out this link which provides the name of the existing community according to specialized subject

There are also various contest is going on in steemit, You just have to enter in this link and then you will find all the contest link, I hope you will also get some interest,

For general information about what is happening on Steem follow @steemitblog.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit