How To Produce Liquid Soap In Nigeria

Liquid soap is becoming a very popular product in the country today. Many use it for domestic purposes at home to wash clothes and kitchen utensils; restaurants and eateries are not left out too. One interesting thing that makes the demand for liquid soap to be very high is the fact that it is easier and cheaper to use than every other washing substances. Little wonder a lot of people are now venturing into the business.

Capital for production is usually very low and one may not require any further teaching since internet has made everything beautiful in this generation of ours.

This is for those who may wish to produce liquid soap by themselves.

Note that there might be other methods used for production, this particular one is one of the best because it is the product of so many researches and expertise, me I Chose the method too.

You may however, stick to whatever method that will best work for you in future. You can start the business today on your own and specialize in the production and marketing of liquid soaps to make a lot of money for yourself.

Liquid Soap

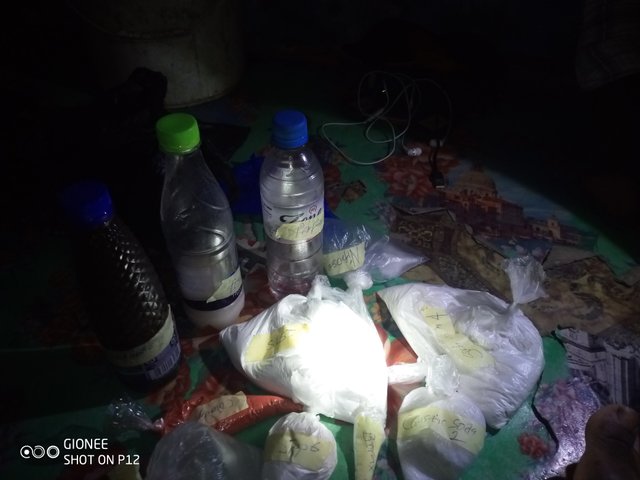

CHEMICALS REQUIRED AND THEIR PROPORTION

The Chemicals required to produce liquid soaps are not far-fetched and are not expensive; they are readily available in our main markets.

Just ask traders around where you can buy chemicals for liquid soap and you will be directed accordingly.

The under listed are for the production of about 20 litres of the soap.

The vendors that sell the chemicals can advise you on the quantities for a smaller volume production like 15 litres or even 10 litres, or as the case may be:

Nitrosol (or Antisol)…….……… 1/8kg (i.e 125g).

Caustic Soda…………………..……1/16kg (i.e 62.5g)

Soda Ash (Sodium carbonate) ,,..1/8 Kg

SLS (Sodium Lauryl Sulphate) ….1/8kg

Sulphonic Acid………………..……..1 ½ Ltr

STPP……………………………….… 1/16Kg

Texapon ………………………….…1/8kg

Foam Booster………………………1/6 Ltr

Formalin………………………………10Cl

Colour (As desired)

Glycerine (Optional)

Perfume (As desired)

Vitamin E (Optional)

DESCRIPTION AND FUNCTIONS OF CHEMICALS USED FOR LIQUID SOAP PRODUCTION

Water:

Water is the main solvent needed for the process to dissolve the various ingredients and also during fermentation phase. It is very essential in the production of liquid soap.

Nitrosol/Antisol:

Nitrosol

This serves as a thickener in the production of the liquid soap. It comes as a whitish substance and has the texture of a powdered milk. Nitrosol will dissolve immediately in water, but Antisol takes longer time to dissolve in water.

Caustic Soda:

Caustic Soda

It is whitish crystalline substances that looks much like a sample of granulated sugar. It forms a strong base when dissolved in water and can be corrosive if in contact with the skin. It is an essential ingredient in the soap making process. This is the stain or dirt removing agent in the liquid soap.

Soda Ash (Sodium carbonate):

Soda Ash

This is also a whitish substance but with much coarse grains, it serves to regulate the concentration of the Caustic Soda which ordinarily is corrosive to the skin. It helps to neutralize it.

SLS (Sodium Lauryl Sulphate):

SLS

The SLS looks like rice grains and it’s whitish in colour too. It is a surfactant which helps to lower the surface tension of the aqueous solution. It is the main active foaming agent.

Texapon:

Texapon

The Taxapon is a pasty and jellylike substance, it also functions as a foaming agent and serves as foaming booster too. Many liquid soap producers don’t use Texapon and SLS together in same production; reason because both perform almost same function. They go with just one.

Sulphonic Acid:

This is a dark looking liquid substance. It serves to boost the performance of the SLS, it is also a foaming and cleaning agent. Please the word spells S-U-L-P-H-O-N-I-C and not S-U-L-P-H-U-R-I-C. The latter is very strong acid and can be very corrosive. please beware.

STPP (Sodium Tripolyphosphate):

STPP is a sodium salt of triphosphoric acid. It has the appearance of white crystal powder and looks very much like a table salt. It is a strong cleaning agent too and helps the SLS to work on its full potential.

Forming Booster:

This also comes in liquid form and has transparent looks. As the name implies, it makes the liquid soap to foam very well.

Formalin:

The preservative agent. It should be used if the soap is to be stored for a long time like six months, especially if one is producing for commercial purposes. Please you can do without this chemical. It is very harmful if abused, it can cause CANCER.

Colour:

This normally comes as a powder and should be diluted with water before adding to the soap mixture. The colour adds beauty to the finished product. Most producers go with green colour.

Glycerine:

Usually helps your skin to remain hydrated and soft after using the soap.

Perfume:

This gives your soap a sweet fragrance. Most people prefer the lemon, pineapple, ambipur. lavender or strawberry fragrance in their production.

Vitamin E:

Offers a great deal of protection to the skin. E.g from damage, wrinkles etc.

OTHER REQUIREMENTS

A big mixing bowl

Containers

Wooden spoon or stick for stirring

A pair of Scissors

Spoon

Measurement bowl or container

Hand glove

Nose mask

Rubber gloves

PROCEDURE

One really needs a great deal of patience during stirring to make sure any chemical added in any stage dissolves properly before adding the next one

For smaller volume production, eg 8litres or 10litres. follow same process but work on your ratios. The vendors selling these chemicals usually sell them already measured according to the volume of liquid soap to be produced. Just tell them how much volume you want to produce and they will give you the quantity of chemicals you require. It is advisable to start with small volume and grow big later. Measure out about 20 litres of water; then follow the underlisted steps:

Ferment the Caustic Soda before production process by dissolving with 1 litre of water and allowing for 24 hours or overnight.

Dissolve the STPP (Sodium Tripolyphosphate) in 1 litre of water before production and keep aside too. (Some people don’t use STPP for whatever reasons best known to them)

Mix the Texapon and Sulphonic Acid together. Mix very well and dissolve further with 2 litres of water. Stirring should be done gently until mixture is well dissolved and homogenous. Note that this particular step is exothermic process; meaning that heat will be generated if you do it well.

Dissolve the powdered colour with small quantity of water and keep aside.

Gently pour the dissolved mixture of Sulponic Acid and Texapon into the mixing bowl containing dissolved Nitrosol(or Antisol}. Stir very well and gently until mixture becomes homogenous. You need patience here.

Add the dissolved Caustic Soda into the mixing bowl above and stir very well.

Add the dissolved Soda Ash next and stir very well until even.

Next, add the STPP and stir properly

Add the Dissolved SLS and stir more.

Add Foam Booster to make it foam very well.

Add your Formalin and keep stirring

Vitamin E and Glycerine can be added at this point. Dont forget to stir and stir.

Finally, allow the lather formed to disappear, then add the dissolved colour and perfume, and stir properly.

Now add the remaining water. Do this gradually, small quantity at a time, stir each time and pay close watch on the thickness until the desired is attained.

Note: Following this order is very important; if otherwise, you may end up producing something you may not like. Some people also believe that the SLS and Texapon should not be used together, that it’s either one uses Texapon alone or SLS alone, but not the two. Like I mentioned earlier, there are diverse methods of production and one should stick to whichever that works for him. For me, I use the two.

More so, the manner one mixes the SLS, Texapon. STPP, Sulphonic and Foaming Booster doesn’t really matter. The important thing is that the Caustic Soda goes into the mixing bowl containing the Nitrosol/Antisol first, then followed by Soda Ash. Then these (SLS/Texapon. STPP, Sulphonic and Foaming Booster), Vitamin E and Glycerine, and Finally Colour and Perfume.

QUALITIES EXPECTED FROM A GOOD LIQUID SOAP

Your soap is expected to foam very well.

It must have a sweet fragrance.

The colour must be appealing.

Must be durable.

Must not cause any form of irritation to the skin.

PRECAUTIONS AND SAFETY DURING PRODUCTION

Wear rubber gloves

Use nose mask

Carryout production in a well-ventilated environment with good illumination.

In case of chemical splash to the face or delicate part of the body, wash very well with plenty water and see a physician as soon as you can.

Keep all chemicals out of reach of children.

Never taste any chemical with the tongue.

Wear your apron or other protective clothing before you commence production.

Most importantly, use your head. Don’t play with chemicals please.

Etc

Thanks for your time!

![IMG_20210207_164326_270.jpg](https://cdn.steemitimages.com/DQmNorQGDUkKQ7uJ4mSroGVQ4qV8ET3bbsJFXU3mXwnR2Uj/IMG_20210207_164326_270.