Compliment of the season to you my reputable Steemians. I strongly believe that you all are enjoying the love of the season. Today, I'll be sharing my yuletide traditional garri processing experience with my family. Enjoy your reading...

INTRODUCTION

Every family has what unites them together during the yuletide and my family don't just use only celebrations to unite us together but also work. It's a custom in my family to process garri during the yuletide before Christmas which will be consumed throughout the festive season until the next year. I love this part of union because I love frying garri (LOL).

GARRI PROCESSING PROCESS

Garri is a popular and mostly consumed food in South-East of Nigeria. It is either soaked and drunk with room temperature water or made with hot water and swallowed with a Nigerian soup. Garri is a by-product of cassava tubers. Traditional garri processing has six (6) stages.

Stage one: Cassava Uprooting

It takes a cassava tuber at least 12 months to be matured for harvest. By this time, one can go and harvest the tubers which is later processed into garri.

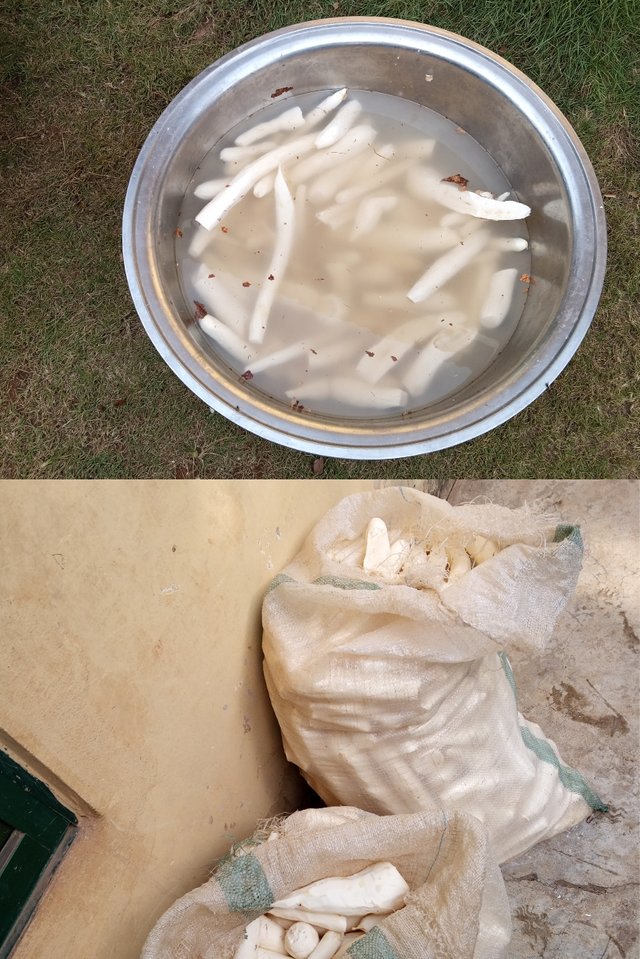

Stage two: Peeling and Washing

After uprooting the cassava from farm, the tubers are peeled and washed with neat water. The washed tubers are then packed in bags and taken to where they would be grated.

Stage three: Grating/Grinding

The machine used for grinding cassava is known as Cassava Grinder. The machine grinds cassava tubers into a molten form which is later poured in a porous strong bag for drying.

Stage four: Drying

After grating the cassava, the molten/ground cassava is poured in a porous bags like empty rice bags in moderate quantity to ease the drying. The bags are closed and stacked in a framework with a wide base. Some hard woods are placed on top of the stacks and a heavy duty hydraulic jack is used to squeeze out water from the ground cassava. For yellow colour garri, the ground cassava is mixed with desired quantity of red oil adequately before pouring into porous bags.

Stage five: Sieving and Frying

After drying the ground cassava, it is sieved using a plastic or metallic sieve to remove chaffs. The sieved garri is fried in a big frying pan to dry very well.

Stage six: Cooling and Storage

This is the final stage. The fried garri is allowed to cool before storage. The garri can be stored in bags or plastic containers depending on your choice.

CONCLUSION

Garri processing is my family custom that I always anticipate whenever I travel home. It's a lovely activity that everyone in the house loves to engage in and more especially, it unites us together. A big thank you to @kingreechy for his mentorship.

Thank you for reading my article.

Hello @mazikenechukwu greetings from Venezuela, I really liked your publication because here in Venezuela we also process cassava, they make cakes called "Casabe" and we call toasted cassava flour "mañoco". Peoples united by their food.

I only speak Spanish, I used a translator.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Wow! This is interesting to know. I hope the cake will be very delicious... Thank you for reading my publication.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Please @mariita52 I need your up vote on the publication... 🙏

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Yes friend, I already voted for your publication, but my voting power is very low.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Okay. Thank you

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit