Namaste steemit

Hello friends, how are you all, hope all is well, today I am going to write my seventh post about my subject. Today in this post we discuss Powder Metallurgy in the manufacturing process. So let's start with the topic.

| What is Powder metallurgy |

|---|

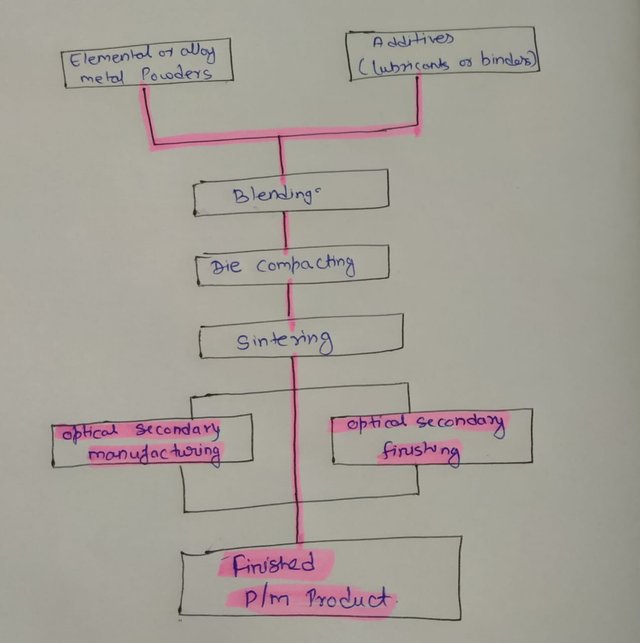

Powder metallurgy is the name given to the process by which powdered material is blended, pressed into the desired shape(compacted), and then heated (sintered) in a controlled atmosphere to bond the contacting surface of the particles and established the desired properties.

Manufacturing of powder

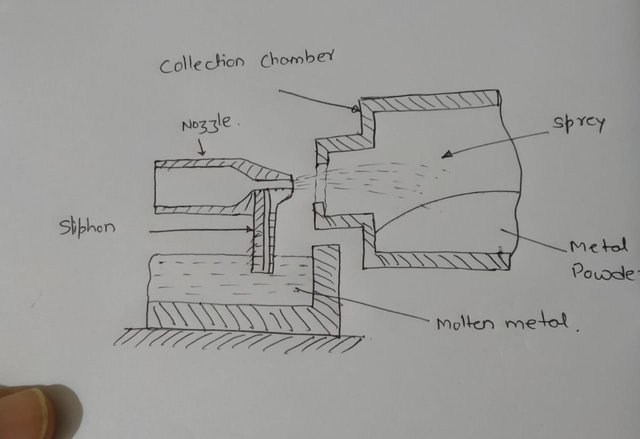

| Atomization using a gas stream |

|---|

|

|---|

Molten metal is forced through small orifice and is disintegrated by a jet of compressed air, you do not guess or water jet. It is used for low melting points, brass, bronze, Zn, Tb, Al, Pb, etc.

| Reduction |

|---|

Metal oxides are turned into pure metal powder when exposed to below melting point gases resulting in a product of cake of sponge metal.

The irregular sponge-like particles are soft, readily compressible, and give compact of good Pre-sinter ("green") strength

Used for Copper, iron, tungsten, Cobalt, Ni, and molybdenum.

| Electrolytic Deposition |

|---|

- Use of iron, copper,

Silver - Process is similar to electroplating.

- For making copper powder copper plates are placed as an anode in the tank of electrolyte whereas the aluminum plates are placed in the electrolyte to act as cathode. When DC is passed, the copper gets deposited on the cathode. The cathode plate is taken out and the powder is scrapped off. The Powder is washed then dried, and pulverized into desired grain size.

- The cost of manufacturing is very high.

Granulations - as metals are cold they are stirred rapidly.

machining - magnesium used as a coarse powder.

Milling - Rollers and Crushers are used to break down metals. for brittle material

Shooting - It means molten metals are dropped in water, and used for low melting point materials.

Condensation - metals are boiled to produce metal vapors and then condense to obtain a metal powder. Used for zinc magnesium cadmium.

|

|---|

| Characteristics of metal Powder: |

|---|

Fineness: refers to a particle size of powder, which can be determined either by poring the Powder through a sieve or by microscopic testing. Standard sieves with mess sizes vary between (100) and (325) and are used to determine particle size and particle size distribution of powder in a certain range.

Particle size distribution: refer to the amount of each particle size in the Powder and have a great effect in determining the flowability, apparent density, and final porosity of the product.

Hii, can also we do tutorial Post ?

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Yes you can .

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thankyou 😊

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit