Japan’s newest bullet train, the N700S, is reusing aluminum alloy from one of its predecessors in a small but significant step forward in the horizontal recycling of aluminum. It looks set to create a pathway for more widespread systematic materials recycling.

It is the first time in the world that aluminum alloy from a decommissioned high-speed rail car has been used in a new one via horizontal recycling – a process that turns the majority of the original product back into a product that is similar to the first.

In this case, the product is parts for luggage racks on the Central Japan Railway Company’s N700S bullet train, which began service on July 1 for travel between Tokyo and cities in western Japan, including Osaka and Kyoto. It is one of the fastest trains in the world.

The luggage racks located above the seats of the new bullet trains. (Image: harita.co.jp)

Already aiming for more

The newly developed recycling method gives the luggage rack parts a materials recycling rate of 10%. But the company aims to do better, and by working with other firms and the aluminum industry, it has helped create a recycling process and a material certification method that may pave the way for broader materials recycling.

“In the future we want to increase the utilization rate (of recycled materials) and explore what other avenues are available in expanding cyclical utilization to other parts of the carriage structure,” a representative of Central JR told The Nikkan Kogyo Shimbun newspaper.

(Image: harita.co.jp)

How to reuse aluminum

The low melting point of aluminum means it can easily be melted and reused. Doing so uses about 97% less energy compared with the amount required at the time of smelting. About 40% of the aluminum alloy used in Japan is recycled, but in fields where the material’s quality and performance must be maintained, it is difficult to reuse aluminum for the same purpose. Recovered aluminum usually contains additives so is typically down-cycled for use in die-casting, for example.

In the Central JR project, however, an efficient new screening method of waste aluminum has enabled it to be recycled at a higher level. Under Laser Induced Breakdown Spectroscopy, a laser analyzes pieces of scrap aluminum alloy on a conveyor belt to determine what additives they contain and group them accordingly. The method was jointly developed by Harita Metal Co., Ltd. and the New Energy and Industrial Technology Development Organization.

Taking a long-term view

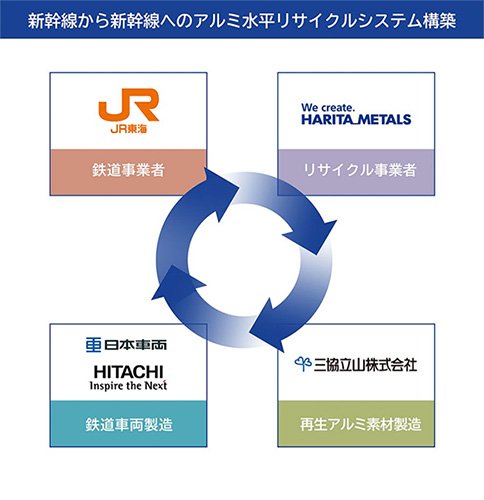

The Japan Aluminium Association also played a role in realizing the horizontal recycling of aluminum in the project. It set up a committee to promote the horizontal recycling of aluminum carriages that includes railway operators, recycling firms, and manufacturers of train carriages and aluminum parts. The committee is developing a process certification method for quality assurance and for other issues.

With these structures in place, Central JR has more than luggage racks in its sights. “Both in Japan and overseas, we want to lead initiatives in the horizontal recycling of aluminum,” said the Central JR representative.

Harita Metal, in a press release, said that it aims to expand the parts range that can be recycled and to further improve the technique. It says it is also researching how to apply the technology to other resources, such as iron and copper. It sees these efforts as helping to create a circular economy that adds value by using resources efficiently and realizes a sustainable society by reducing environmental impact while maintaining economic growth.

A partnership to create a circular system for recycling materials. (Image: harita.co.jp)

Where there’s a will there’s a way

Technological developments are giving us hundreds of new ways to process old things. Now that corporate thinking is catching up with environmental commonsense, companies are recognizing the financial motivation to lead recycling and other developments that help create a sustainable economy. Technologies that they develop can be sold to industries throughout the world to benefit them financially.

Japan is good at taking an industry-wide approach to new technologies and establishing industry standards, which hopefully will hasten the expansion of new techniques for the reuse of resources.

(This article was originally published on Zenbird Media.)

Additional Resources

Zenbird Media Homepage

More on recycling in Japan

More articles surrounding circular economy