From design to implementation.

Blacksmithing is one of the oldest professions on the planet, I imagine that since man has dominated iron, he is making functional pieces and arts, I think that will not change, well for a long time.

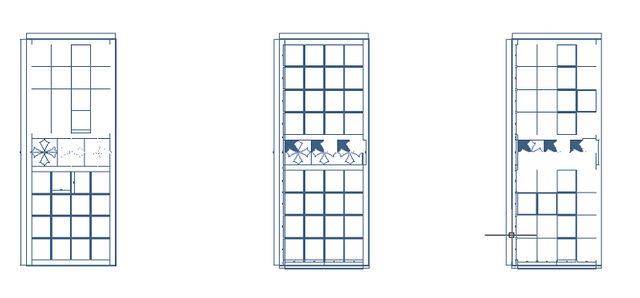

Today I will show you the stages of construction of a metallic door that will be placed in a basement, the design came out like this, because of the material that it had, later I will explain it to you because the designer should adapt to the materials that it had, well that in the In case of having limited resources, but despite this, a beautiful design came out in my opinion and fully functional.

The tools that were used were the following.

- Welder, electrodes and welding mask.

- Safety equipment, gloves, glasses and others that you deserve.

- Hammer, punch, press, pliers.

- Drill, emery and polisher.

The main skeleton of the door was made by making boxes to embed each piece, it was made in this way because security was required, since it is the first door in the work and it will be used as a warehouse for materials; In addition to this, it was polished iron that does not reach 1mm in thickness, the greatest structural strength is sought.

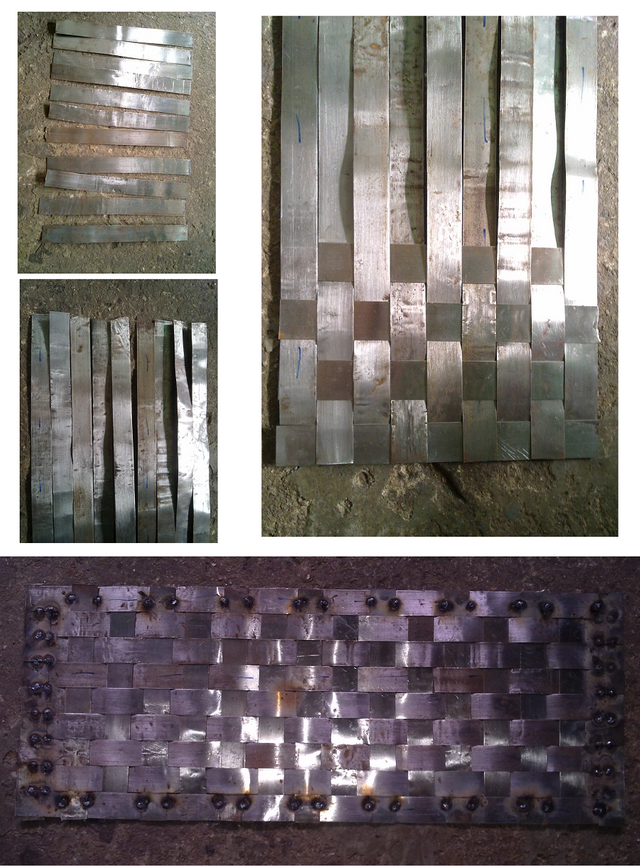

Once the skeleton of the door is made; We proceeded to weld and cover the quadrants, these quadrants were covered with sheets. They are cuttings that I was sold in different smithies and they were cheaper if instead I bought the complete piece; These were scored and bent with a metal bender.

Then they were fixed in their space, giving it small weld stitches so that it was well fixed and giving strength to the door.

The central part was made a metallic "weave" to get enough flat surface to cover the central part of the door, as seen in the figure the metal slats were intertwined, which in this case are strips that they gave me and I took advantage of them .

Subsequently, the contour was welded so that it would not come apart and the edges were bent to give it greater rigidity and strength to the structure.

Several stars were made which is the main motif of the door.

Once all the pieces had been fixed, we proceeded to weld the hinges and open the opening where the lock goes, in addition, additional pieces were cut out to be embedded.

Once made, it was taken to the site to be placed, the door was placed without a frame for reasons of economy, the hinge and lock brackets were fixed first; then it was fixed with cement or concrete to give it stability in place.

That's how I stay, the results were good, I was straight and level; We proceeded to paint it in the background to protect it from corrosion, while it is decided to paint it in its final color. I hope you like it, let me know what you think and if you have placed a door.