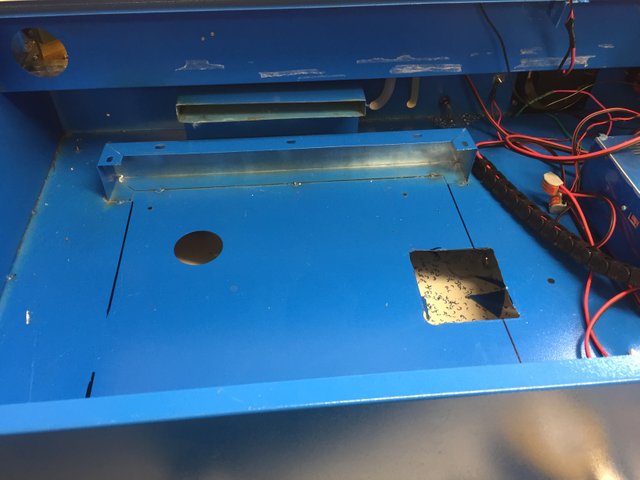

Here I measure out the area that needs to be cut out

Using the Air nibbler tool I start to cut out the base of the K40 laser cutter sheet metal.. It only just gets through this material so it takes some time

All cut out - there is a lot of mess - Those metal ring cut thingos get everywhere.

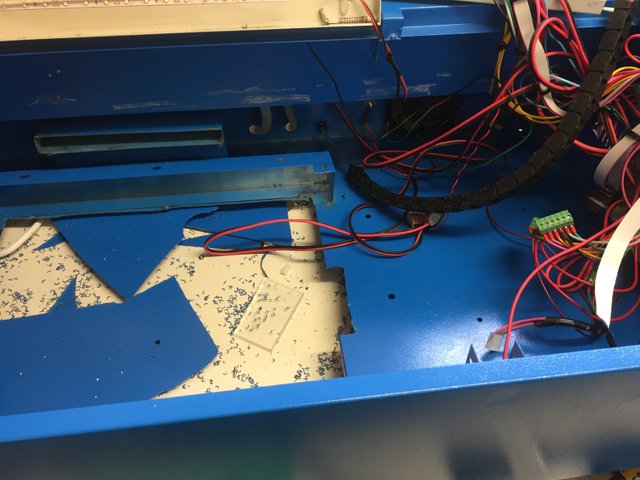

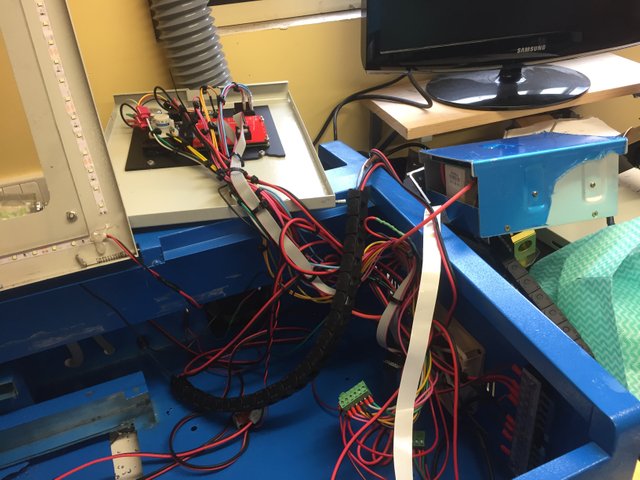

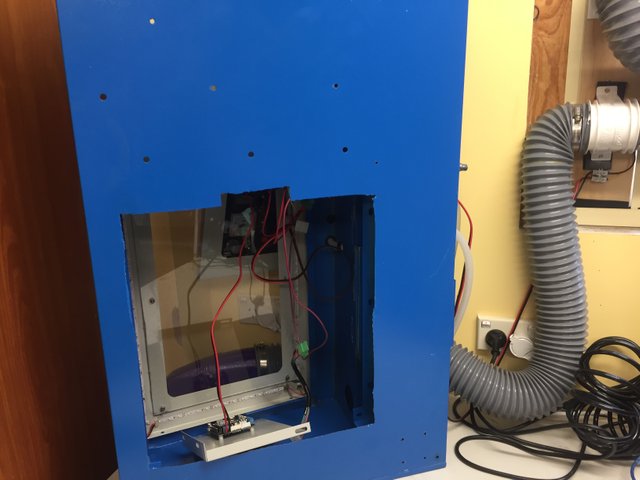

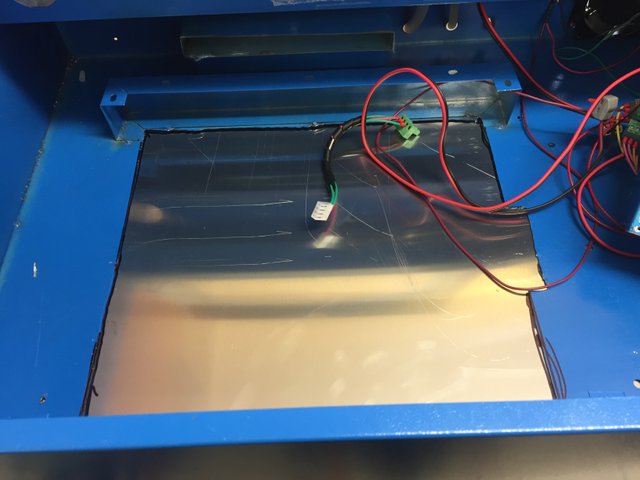

I need to make room to work, so I start to remove the inside guts of the laser cutter

All that remains is the control board and a few wires

Here is a 1000mm x 500mm sheet of 3mm aluminium flat sheet that was bought and cut at paramount browns earlier today (see previous blog post)

I put the laser cutter down on the aluminium sheet where I want it - center of the sheet - and then draw out where the hole needs to be cut out of the sheet

As we can see here there is 95mm on each side sticking out - this is intentional.

So using a 260mm by 240mm aluminium sheet that was also cut earlier, I then neaten up the lines marked on the main sheet

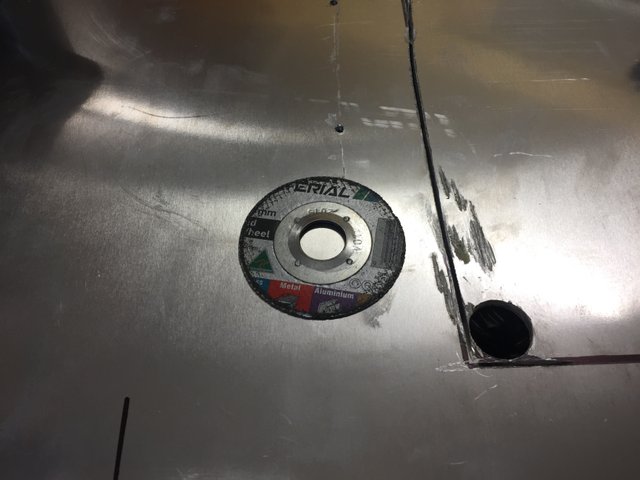

As you can see here, I drilled a 20mm hole in one of the corners in the hope that I could use the air nibbler. Unfortunately the 3mm is too thick for that.. So I bust out the dremel tool and try to start cutting. Turns out it was useless. Being a softer material, the cutting disk caught and there wasn't enough torque in the dremel tool to overcome this.

So I tried with my angle grinder with a cutting disk. I only had half a cutting disk left after a previous job so I only managed to cut a little bit before this disk was worn out.

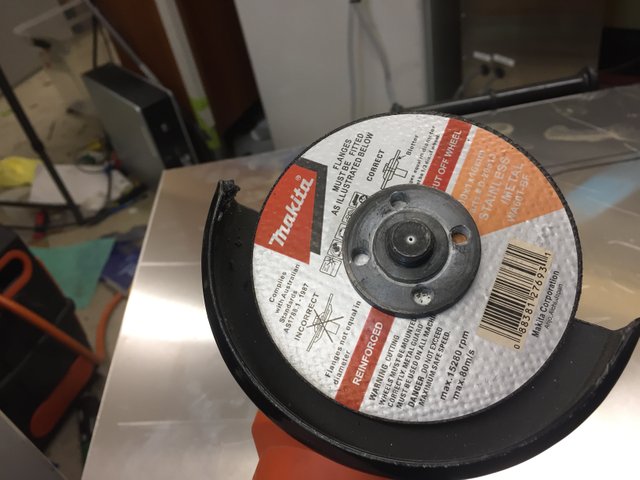

A quick 30 minute trip to Bunnings in the rain let me pick up another 12 cutting disks in a handy dandy container!

Installed the cutting disk onto the angle grinder

Cut out the hole. As you can see saftey was paramount and the work piece was secured correctly before using the cutting wheel......... OK don't do what I did here.. ever. I used my wheely bin as a make shift table. You can see the apprentice marks all over this as a result... also, it didn't help with making a straight cut.. oh well

I cleaned up the edges with a sanding flap disk on the angle grinder

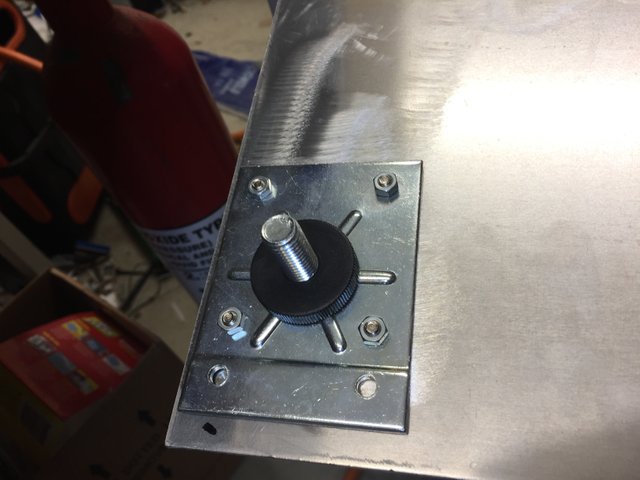

Here I am installing the legs to the bottom of the sheet.

The legs are secured with 4mm screws and nuts

Congratulations @rativiv! You have completed the following achievement on Steemit and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Join our Discord Channel to connect with us and nominate your own or somebody else's posts in our review channel.

Help us to reward you for making it ! Join our voting trail or delegate steem power to the community account.

Your post is also presented on the community website www.steemmakers.com where you can find other selected content.

If you like our work, please consider upvoting this comment to support the growth of our community. Thank you.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit