Archeological evidence has revealed that we even import iron nails from abroad, we produced iron 2900 years ago and even sold it abroad. This is a survey of our ancient iron technology.

Prehistoric times

According to the Mahavamsa, our metal technology dates back to 3000 BC. The fact that we knew metal technology in prehistoric ages is also proved by the precious items found in the great stone burials. In the past, the first metal used in our country was copper. It has become clear that the production and use of iron started after that.

About 5000 years after the use of copper metal in Sri Lanka, the production and use of iron took place. Evidences are also found in historical sources that Sri Lankans who produced very high quality iron exported those metals to foreign countries. It is clear from the archaeological excavations of Sigiriya Alakol Lake that the iron technology of Sri Lanka dates back to 900-1000 BC (more than 2900 years from today).

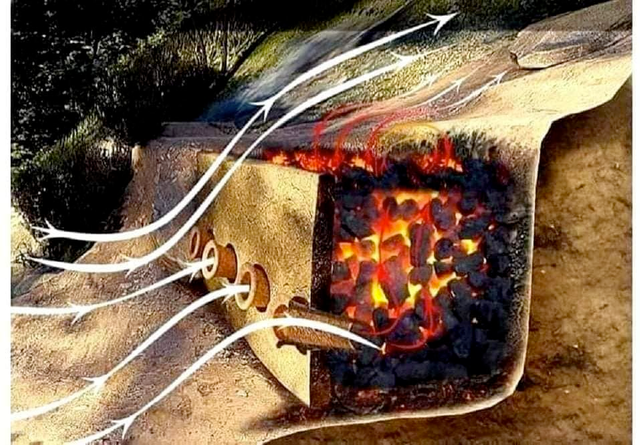

In order to separate the iron metal from iron-rich rocks found in the natural environment, they must be heated to high temperatures. A temperature of 1538 degrees Celsius is required to melt iron. Thus, it is necessary to have an efficient technology to obtain a high temperature. Iron furnaces used in the past to separate iron from iron ore Balangoda Samanalaweva. It has been found in Sigiriya Alakola Lake and Wewala in Dambulla, Panirendawa in Puttalam district, Ridhigama etc.

Scholars like Robert Knox, John Davy, Ananda Coomaraswamy have mentioned about our old traditional metal technology in the Kandy era. The traditional metal technology that existed until the beginning of the last century was then lost to us.

Connection with India

Dr. Siran Deraniyagala and Dr. Sudarshan Senaviratne have pointed out that Sri Lanka's metal industry has connections with the great stone culture groups of Peninsular India. Sudarshan Seneviratne has mentioned that Hematite and Limonite as well as Magnetite were the main metal raw materials used to obtain iron in the prehistoric era of Sri Lanka. Archaeological research has revealed that hematite and limonite can be identified on the surface of the earth in the North-Central Province and the North-West Province.

AD B.C. It has now been recognized that the technology of producing metals occurred in the North-Central and North-West Provinces, Anuradhapura Valley, Yanoya Valley, Ibbankatua, Andarawewa, Yapahuwa Pingwewa Galsohon Kanatta, Polpithigama etc. between 1000-800. The development of metal technology in Sri Lanka after 700 BC has been confirmed by the metal artifacts found in Anuradhapura and the north-western Pomparippu. By that time, our artisans knew how to produce good iron and steel.

Balangoda Iron

Balangoda Samanalaweva is a major place that provides examples of the ancient technology of iron extraction in Sri Lanka. The area where the iron furnaces were located was submerged in the Samanalaweva reservoir. Ananda Kumaraswamy mentions that iron was produced around Balangoda even at the beginning of 1900. Ananda Coomaraswamy's Medieval Sinhala Art Work, printed in 1908, has included many facts about the iron industry in Ceylon.

According to him, at that time, only Balangoda was producing iron from Sri Lanka's iron ore. He met two old men in Balangoda who knew how to turn iron into steel. He mentions that with the death of those two, that industry also belongs to the past:

Iron ore is smelted by the Yamannu of Chaturaba near Balangoda. The ore is collected and put into the furnace to extract the iron. Before smelting, the ore pieces are broken into small pieces and heated to remove moisture. The fireplace is powered by coal. The bottom of the stove is covered with sand. In between, the winds are constantly blowing. After three hours or so, the iron is set. The Sri Lankan steel industry is already dead. Steel was not made for trade recently. Also the old people who make it cannot live long. But few families are partially engaged in iron smelting. (Medieval Sinhala Art- 187 pages)

Coomaraswamy mentions that the iron made in this way is soft and one lump weighs about six pounds. He says that one ball of iron produced is sold to Acharin for making weapons for fifty cents.

Samanalaweva iron furnaces

Ancient iron furnaces were first found during the archeological survey conducted in 1988 in the areas under the reservoir before the construction of Samanala Lake reservoir. There, 139 places related to iron were found. Later, in the early 1990s, further archaeological excavations in Samanala Lake Valley revealed clear evidence of iron production technology.

Iron was mined in Samanala Lake around the third century BC. Natural wind power has been used to light the stoves used for that purpose. Facts were revealed about 41 places with stoves.

Pieces of natural stone containing iron are cut into clay furnaces and charcoal is added to it. After lighting the fire in the evening, the furnace burns until the next morning due to the force of natural wind currents and the iron is separated.

Iron-rich rocks such as limonite and hematite have been used to extract this iron. Charcoal obtained by burning trees known as 'Marang' or Iron Marang is used to light the fire in these stoves. Marang trees can still be seen around Balangoda today.

Archaeological factors

During the archaeological explorations, Galevalahinna P., located south of Belihul Oya, was first discovered

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Upvoted! Thank you for supporting witness @jswit.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit