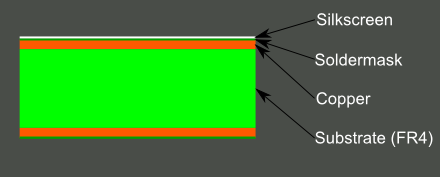

PCB的构成

- 玻璃纤维,也就是FR4,构成PCB的基层;

- 铜箔,PCB中构成电子电路互联的导线;

- 阻焊,也就是所谓的绿油层,保护电路,防止短路;

- 丝印,PCB中元器件等的信息标志。

PCB制作流程

- 在制作其它层前,先制作内部的玻璃纤维层(芯板层),是其它层的基础;

- 添加铜箔层,在玻璃纤维的上下各添加一层铜箔;

- 添加铜箔式样,将PCB设计的层压合板放在铜箔层的上面,来指示PCB设计中需要的铜箔;

- 确定铺铜式样,将层压合板和铜箔上铺上光刻胶卷,并放到紫外光灯下照射,这样铜箔就会被腐蚀出PCB设计中需要的线路;

- 清洗,将PCB放在化学试剂中清洗,去掉不需要的铜,保留需要的铜箔线路;

- 给铜箔刷绿油以保护铺铜线路;

- 添加丝印,成为“裸板”;

- 安装元器件。

参考文章

Printed Circuit Boards from 10,000 Feet – An Introduction for Electronics Beginners

Thank you so much for being an awesome Partiko user! We have just given you a free upvote!

The more Partiko Points you have, the more likely you will get a free upvote from us! You can earn 30 Partiko Points for each post made using Partiko, and you can make 10 Points per comment.

One easy way to earn Partiko Point fast is to look at posts under the #introduceyourself tag and welcome new Steem users by commenting under their posts using Partiko!

If you have questions, don't feel hesitant to reach out to us by sending us a Partiko Message, or leaving a comment under our post!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit