What is a Manual Globe Valve?

The Manual Globe Valve is one type of valve used in pipe systems to regulate fluid flow. Here are some salient features about it:

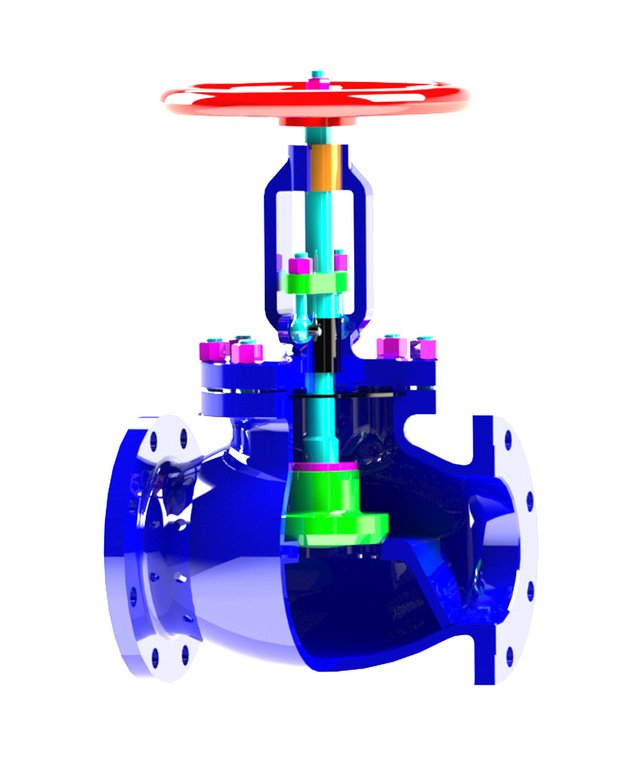

Design: Has a spherical body that may be adjusted to control flow via a moveable plug or disc.

Operation: Handwheels or levers are used to raise or lower the valve's stopper manually.

Control: Offers exact control over pressure and flow rate.

Construction: Metals are usually used for durability.

Application: Frequently utilized in gas, oil, and water pipeline systems when throttling and flow control are required.

Flow Path: The fluid travels through a globe-shaped chamber to reduce noise and turbulence.

Pressure decrease: Because of the obstruction in the flow channel, there is a pressure decrease.

Maintenance: Frequent maintenance is necessary to guarantee correct operation and stop leaks.

Installation: Although it may be put in any orientation, it is often done horizontally to simplify operation.

Benefits: It offers superior flow control compared to other valve types, such as gate valves, particularly at lower flow rates.

Advantages of Manual Globe Valves:

The following are a few benefits of manual globe valves:

Precision Control: This feature makes it perfect for applications needing precision regulation as it enables fine-grained adjustment of pressure and flow rates.

Throttling Capabilities: Unlike gate valves, primarily used for on/off control, these valves are effective in throttling or modulating flow.

Leak Prevention: When closed correctly, it usually creates a tight seal that lowers the chance of leakage.

Versatility: Fits well with oil, gas, and water systems, among other uses.

Flow Efficiency: The globe valve's construction minimizes noise and turbulence in the flow channel.

Manual Operation: Easy to use with a lever or handwheel, this device doesn't need additional power sources or control systems.

Maintenance: They require less maintenance because they have fewer moving components than certain automated valves.

Adaptability: Easily put in any direction; however, horizontal placement is most usual for optimum functioning.

Economical: frequently less expensive than intricately programmed valves, particularly in smaller systems.

Qualities of Top Globe Valve Manufacturers:

The following are the crucial qualities of top Globe Valve Manufacturer:

Superior Materials: Because of their strength and resistance to corrosion, premium materials like brass, stainless steel, or alloy metals are recommended.

Dependable manufacture: Advanced engineering and production methods guarantee precise and trustworthy valve performance.

Thorough Testing: Extensive testing protocols that validate functioning, pressure resistance, and leak-stopping capabilities.

Innovative Design: State-of-the-art layouts that boost efficiency overall, minimize pressure drop and increase control.

Certification and Compliance: Following industry rules and guidelines to guarantee dependability and safety.

Superb Customer Service: Prompt customer support and technical assistance for installation, maintenance, and troubleshooting.

Broad Product Selection: Providing a varied range of globe valves to satisfy different application requirements and standards.

Expertise and Reputation: A person's trustworthiness and dependability are attested to by their extensive industry experience and reliable track record.

Sustainable Practices: Sustainable practices refer to using environmentally friendly techniques and sustainable ways of manufacturing.

Advantages of Buying from Leading Globe Valve Manufacturers:

Purchasing from reputable globe valve manufacturers has the following benefits:

Trustworthy suppliers offer premium valves that pass stringent testing to guarantee performance and dependability.

The valve is more resilient to wear and has a longer lifespan when premium materials and cutting-edge manufacturing processes are used.

Accurate pressure and flow regulation are provided by precision control, which makes them perfect for systems that need that kind of control.

Availability of sophisticated, optimized designs that improve utility and efficiency.

Reputable producers provide dependable customer support for upkeep and repairs along with warranties.

Products frequently comply with industry standards and laws to guarantee safety and interoperability with a range of systems.

What is a Manual Gate Valve?

Design: The flow passage may be opened or closed by moving a gate or wedge-shaped disc up and down.

Operation: A handwheel or lever manually raises and lowers the gate.

Function: This is mostly employed for completely open or fully closed situations rather than flow regulation or throttling.

Flow characteristics: When fully open, it offers minimum resistance and pressure drop, enabling unhindered flow.

Uses of Gate Valves:

Control Flow: A mechanism used in municipal water delivery systems to regulate water flow.

Isolation: Perfect for separating pipeline segments for upkeep.

High Pressure: Fits high-pressure uses in pipes serving the oil and gas industry.

Corrosion Resistance: Frequently constructed using materials resistant to hydrocarbon-induced corrosion.

Advantages of Manual Gate Valves:

The following are a few benefits of a Manual Gate Valve:

Unrestricted Flow: When gate valves are fully open, fluid has a clean, direct passage, reducing flow resistance and pressure drop.

Simple Design: Compared to other valve types, they have fewer moving components, which makes maintenance and repair easier.

Durability: Built using sturdy materials that increase its strength and lifespan, such as steel, cast iron, or stainless steel.

Suitable for On/Off Control: Better suited for situations when a valve must be completely open or closed than for throttling or controlling flow.

Cost-Effective: They are a cost-effective option for various applications since they are frequently less expensive than complex valve types.

Versatile Application: Suitable for pipelines carrying gas, oil, and water, among other fluids and systems.

Minimal Pressure Drop: Gate valves are perfect for situations where a straight, unhindered flow is required since, when completely open, they provide very little resistance to flow.

Full Passage: The design is efficient for high-flow applications since it permits full fluid passage with no impediment while the valve is open.

Deciding Which Valve Is Best for Your Needs:

Utilization Conditions: Assess your needs and decide if a gate or globe valve will provide complete flow separation.

Pressure and Temperature: The valve's material and design should withstand the pressure and temperature levels in your system.

Maintenance and Durability: Depending on your application, assess the valve's predicted lifespan and simplicity of maintenance.

Cost considerations: To choose the valve that best suits your needs, consider its price against its durability and performance.

Manufacturer Reputation: To guarantee quality and dependability, use valves from respected manufacturers. A trustworthy supplier of globe valves or gate valves may deliver goods that satisfy industrial requirements and give excellent customer service.