Understanding MIG Welding Machines: A Comprehensive Guide

MIG (Metal Inert Gas) welding, also known as Gas Metal Arc Welding (GMAW), is a popular welding process used in various industries for its efficiency and versatility. In this blog, we’ll explore the fundamentals of MIG welding machines, their components, advantages, and applications.

What is a MIG Welding Machine?

A MIG welding machine uses a continuous solid wire electrode fed through a welding gun, which is melted and fused to the workpieces. The process uses an inert gas, typically argon or a mix of argon and carbon dioxide, to shield the weld from contamination, ensuring a clean and strong weld.

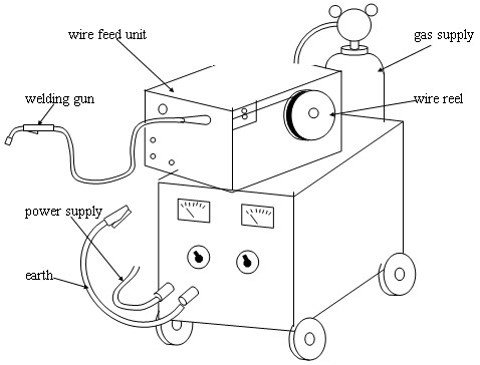

Key Components of a MIG Welding Machine

- Power Supply: Provides the necessary voltage and current for welding.

- Wire Feed System: Automatically feeds the welding wire at a controlled speed.

- Welding Gun: Delivers the welding wire and gas to the weld area.

- Gas Cylinder: Contains the inert gas used for shielding.

- Regulator: Controls the flow of gas from the cylinder to the welding gun.

Advantages of MIG Welding

- Speed and Efficiency: MIG welding is faster than other welding processes due to the continuous wire feed.

- Ease of Use: It requires less skill compared to other methods, making it accessible for beginners.

- Versatility: Works well on a variety of metals and thicknesses, including aluminum and stainless steel.

- Clean Process: The inert gas shielding minimizes contamination, resulting in high-quality welds.

Common Applications

MIG welding is widely used in various fields, including:

- Automotive Industry: For manufacturing and repairing vehicle components.

- Construction: Used in fabricating steel structures and components.

- Home Projects: Ideal for DIY enthusiasts working on metal fabrication.

Conclusion

MIG welding machines are invaluable tools in modern welding practices, combining speed, efficiency, and versatility. Whether you're a professional welder or a hobbyist, understanding how these machines work can enhance your welding projects and lead to better results. Consider exploring different models and features to find the right MIG welder for your specific needs.

Final Thoughts

If you have experience with MIG welding, share your insights and tips in the comments below! Let's create a community of welding enthusiasts who can learn from each other’s experiences.