Most opaque materials begin to let the light through if we cut them into a sheet thin enough. A team of researchers at the University of Michigan has achieved a thin sheet of silver that is transparent, and can revolutionize the way we manufacture mobile phones.

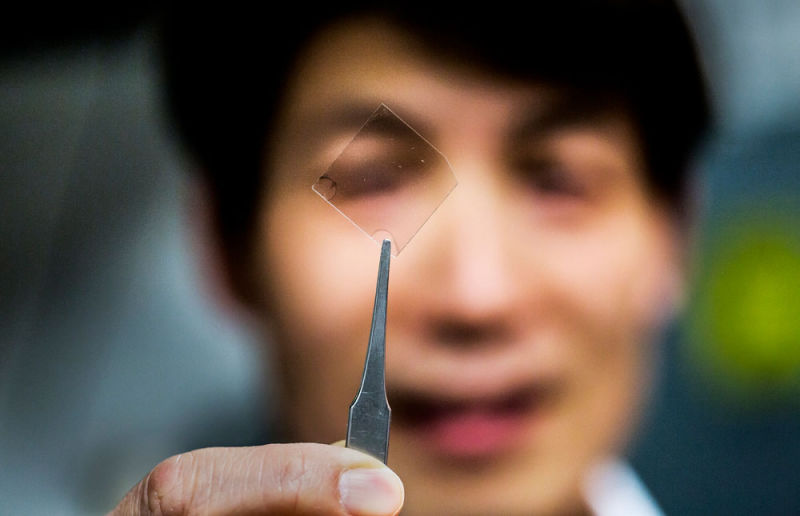

Silver is not an easy-to-cut material. In fact, it was considered impossible to fabricate a sheet of less than 15 nanometers (about 100 silver atoms) because of the tendency of the metal to form clusters at the molecular level. The equipment has solved this problem by adding 6% aluminum. The result is a sheet of only 7 nanometers that also does not tarnish in contact with the air like the normal silver objects.

What is the point of creating a sheet of silver of that thickness? The first answer is probably in your pocket: the mobiles. The screens of today's smartphones need a transparent sheet that contains the electrodes to give tactile support to the screen. The most used material for this medium is Indium Oxide, and Indium is an increasingly scarce and increasingly expensive metal.

The silver foil not only offers a 92.4 transparency, but in turn is an excellent conductor of electricity. In other words, it is an ideal candidate to replace the electrode layer of the current screens with a thinner one that, moreover, is flexible.

Moreover, the silver of this thickness exhibits a series of very unusual properties of light polarization that would allow its use to develop optical cables of a thickness suitable for use in microelectronics. Traditional optical fiber does not withstand such extreme reduction as to serve in an integrated circuit. Transparent silver could be the start of a new generation of optical chips.