With the exponential growth in AI model training and inference demands, the need for computing power has surged, driving a significant increase in network bandwidth requirements for AI data centers. This trend has accelerated the development of high-speed optical modules, which serve as critical components in data centers and high-performance computing systems by enabling high-speed, high-capacity data transmission.

There are two primary methods for increasing bandwidth in optical modules:

- Increasing the bit rate per channel, either by directly raising the baud rate or by maintaining the baud rate while adopting more advanced modulation schemes such as PAM4.

- Expanding the number of transmission channels, either by increasing the number of parallel optical fibers or by employing Wavelength Division Multiplexing (WDM) techniques such as CWDM and LWDM.

Based on the transmission method, optical modules can be classified into parallel optical modules and WDM optical modules. Parallel optical solutions are particularly cost-effective for short- to medium-distance transmissions, whereas WDM solutions are more advantageous for long-distance transmissions as they significantly reduce fiber costs.

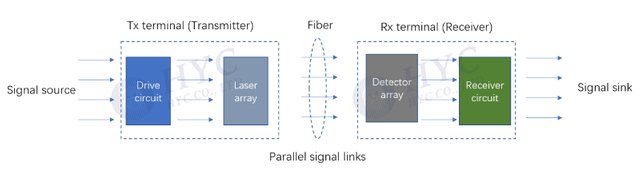

Parallel optics transmission

For parallel optics transmission, parallel optical modules at both ends of the link contain multiple transmitters and receivers, utilizing multiple optical fibers to transmit and receive signals through multiple paths. Common parallel optical module types include SR4, SR8, PSM4, DR4, and DR8.

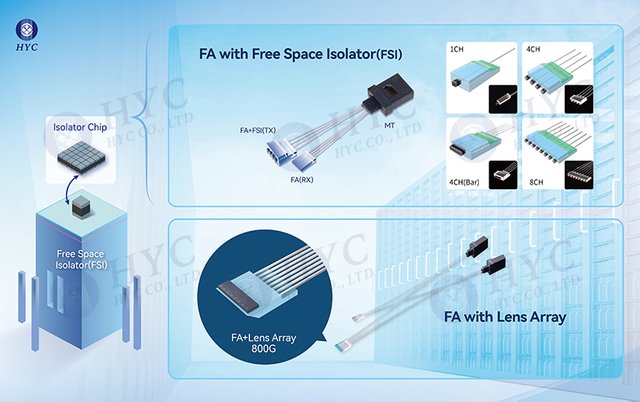

MT(MPO) and fiber array (FA) assemblies are key components for parallel optical interconnections, which can be integrated into optical modules to connect external and internal optical connections. The compact size and multi-channel capability of MT ferrules make them ideal for high-speed parallel optical transmission. Since different optical module types and manufacturers have unique internal structures, MT-FA and MT-MT jumpers are highly customized. Various configurations include MT-FA, MT-2×Mini MT, MT-FA with isolators, and MT-FA with lens arrays.

FA with isolators or lens array products are widely used in high-speed optical modules. The primary function of an isolator is to effectively prevent optical signal reflections, allowing only unidirectional light transmission based on the non-reciprocal properties of Faraday rotation. In traditional optical modules, isolators are typically used as standalone components. Integrating a fiber array with an isolator simplifies module design, optimizes space utilization, and reduces coupling time while ensuring high-quality signal transmission.

Lenses play a crucial role in optical transceiver modules by facilitating optical coupling. Since laser emissions are divergent, lenses help collimate or focus the light beam to improve transmission efficiency. On the receiving end, as data rates increase, photodiodes (PD) receiving area becomes smaller, making direct fiber-to-PD coupling less efficient. This is where lens arrays become essential, as they effectively improve coupling efficiency by focusing light onto the PD. Additionally, they simplify optical module packaging, reduce manufacturing steps, and lower production costs. Both FA and lens arrays can be customized based on beam profile, angles, and specific customer requirements to achieve precise optical coupling.

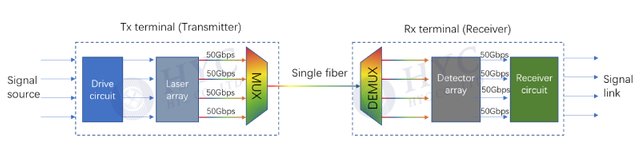

WDM optics transmission

WDM technology enables the transmission of multiple wavelength signals over a single optical fiber, significantly increasing fiber transmission capacity. It has been widely adopted for medium- to long-distance optical communication and data center interconnects. Typical WDM optical module types include FR4, FR8, and LR4.

WDM can function as either a multiplexer (MUX) or a demultiplexer (DEMUX). A Demux separates incoming multi-wavelength WDM signals into individual wavelengths, and couples them into photodiodes for optical-to-electrical conversion. A Mux combines different wavelength signals from multiple laser sources into a signal, which is then efficiently coupled into a single output fiber.

WDM optical components consist of several discrete functional components. On the receiving end, these include fiber collimators, WDM blocks, mirrors, lens arrays, and prisms, while the transmitting end typically includes collimators, isolators, and WDM blocks. Precision alignment is required between these discrete components to ensure optical performance. As the demand for high-speed and high-density modules grows, integration has become increasingly important, which can simplify optical coupling processes, enhance production efficiency and improve product consistency.

There are two main technologies used for implementing WDM optics technology in optical modules:

- Thin-Film Filters (TFF), based on free-space optics;

- Planar Lightwave Circuit (PLC)-Based Solutions, including Arrayed Waveguide Gratings (AWG), Echelle Diffraction Gratings (EDG), and Cascaded Mach-Zehnder Interferometers (MZI).

Among these, TFF (using the Z-Block technology) and AWG are the most commonly used and representative MUX/DEMUX subcomponents.

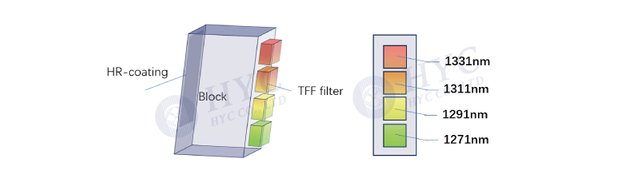

TFF technology in optical modules typically utilizes the Z-block method. It is based on a free-space optics design, combined with collimators, and incorporates four CWDM wavelength filters to perform multiplexing and demultiplexing. The transmission wavelengths of each filter are 1271nm, 1291nm, 1311nm and 1331nm respectively.

The diagram below shows the typical structure of a Z-block. In the center is a processed rhombohedral prism (also a parallelogram-shaped glass substrate), with the backside of the prism coated with a high-reflection film. On the opposite side, WDM filters for different wavelengths are applied. Each filter only allows light signals of the current channel's wavelength to pass through, while reflecting the other wavelengths, thereby selecting a specific wavelength beam for transmission.

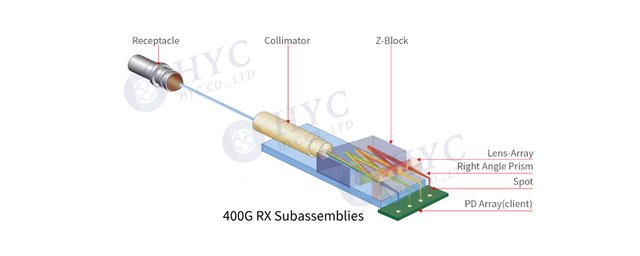

A typical 400G Rx optical integrated subassembly based on Z-block technology which integrates all key components of 400G ROSA, including receptacle, collimator, Z-block, lens array, prism, and baseplate. With just one coupling step to assembly into transceivers, greatly simplifying the process.

Z-block technology offers the benefits of low loss and good channel quality but involves complex manufacturing processes. Several key assembly control factors must be considered:

- Z-block surface dimensional accuracy: Critical for maintaining collimator beam quality.

- Focal spot position tolerances (X/Y/Z axis): Optical simulation techniques are required to ensure precise alignment with the PD.

- Mechanical and environmental reliability: High shear force and HAST requirements ensure product reliability and stability in applications.

HYC provides fully customized optical coupling solutions for optical transceivers, covering both PD-to-Fiber and LD-to-Fiber connections, including 2-channel, 4-channel, 2×4-channel LAN-WDM/CWDM Block and BIDI Block, tailored for ROSA, TOSA, BOSA, etc.

As optical networks and data centers advance toward ultra-high speeds, greater capacity, and higher integration, optical transceiver modules are adopting more compact and highly integrated solutions. This trend is fueling a rapid surge in demand for both parallel optical subassemblies and WDM optical subassemblies.

About HYC Co., Ltd

Founded in 2000, HYC is a leading global manufacturer of innovative and reliable passive optical components. HYC designs, develops, manufactures, and sells a comprehensive line of passive optical devices that enables 5G/6G, data center, data communication, FTTH, aeronautical communication networks.